Peripheral pump

A technology of vortex pump and pump cavity, applied in the field of vortex pump, can solve the problems of short service life and high noise, and achieve the effect of enhancing stability, reducing noise, and being convenient to take.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

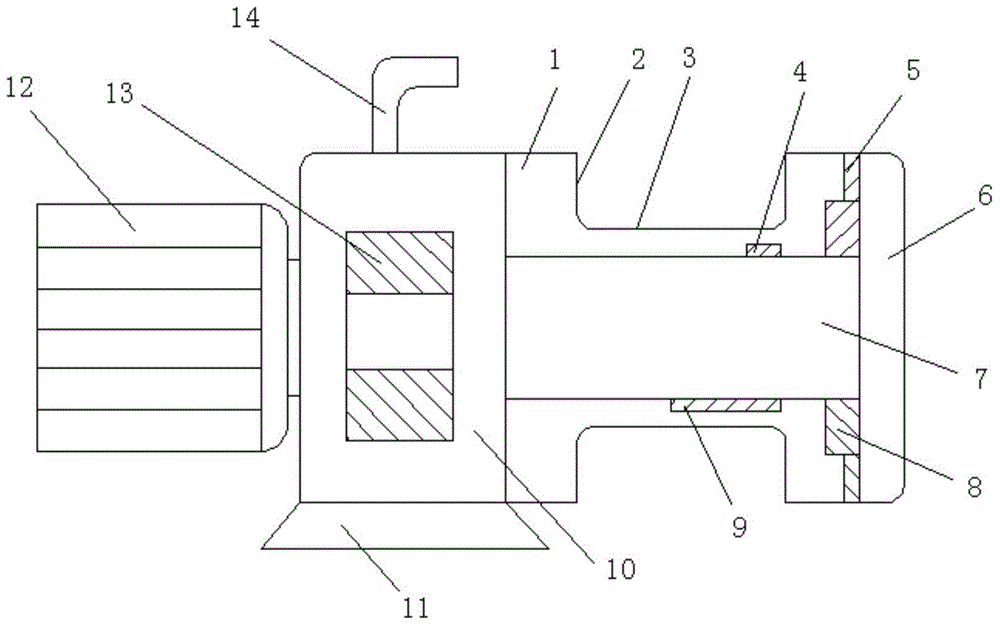

[0016] This embodiment consists of a pump chamber housing 1, an annular groove 2, an inner wall of the housing 3, a groove 4, a shock absorbing gasket 5, a pump cover 6, a pump body 7, a bump 8, a sealing ring 9, a connecting frame 10, Base 11, motor 12, coupling 13, handle 14 form.

[0017] The left side of the pump chamber casing 1 is provided with a connecting frame 10, the interior of the connecting frame 10 is provided with a coupling 13, the left side of the connecting frame 10 is provided with a motor 12, and the top of the connecting frame 10 is provided with a handle 14, which is convenient for the vortex pump. The bottom of the connecting frame 10 is provided with a base 11, which supports the entire vortex pump. The pump body 7 is wrapped by the inner wall 3 of the casing, and the outside of the pump body 7 is provided with a pump chamber casing 1. The pump cover 6 is connected by bolts, and the connection between the pump chamber shell 1 and the pump cover 6 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com