Dust-separation anti-explosion lamp

An explosion-proof lamp and dust-proof technology, which is applied in the direction of gas-proof/water-proof devices, separation methods, lighting and heating equipment, etc., can solve the problems of ineffective prevention of explosion and heating on the surface of electrical equipment, and reduce the probability of dust explosions. The effect of reducing the probability of dust explosion and reducing the dust concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

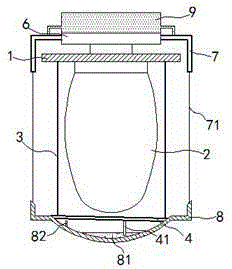

[0014] exist figure 1 In the shown embodiment, the dust-proof and explosion-proof lamp includes a base 1 and a lamp body 2; an explosion-proof curtain 3 made of a good heat-conducting material is wrapped around the periphery of the lamp body 2; the upper end of the explosion-proof curtain 3 is fixed On the base 1, the lower end of the explosion-proof curtain 3 is connected and sealed by an evaporation net 4; a drive turntable 6 is also installed on the base 1, and the drive turntable 6 is driven by a micro drive motor; A dust-proof cover 7 is installed on the drive turntable 6, and dust-proof wires 71 are evenly distributed circumferentially on the lower edge of the dust-proof cover 7; Dust-absorbing glue 81 is injected into the dust collection tray 8; the dust collection tray 8 is rotationally connected with the evaporation net 4; the angle between the evaporation net 4 and the two planes where the dust collection tray 8 is located is 3 -10 degrees; on the dust collection tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com