Device for balanced suspension of dip angle burners with double constant-force spring hangers

A constant-force spring and spring hanger technology, which is applied in the direction of using a variety of fuel combustion, combustion methods, combustion types, etc., can solve the problems of inability to use and directly arrange constant-force spring hangers in parallel, and achieve reliable suspension, The way of arranging the inclination and suspension is flexible and changeable, and the effect of solving the difference of expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

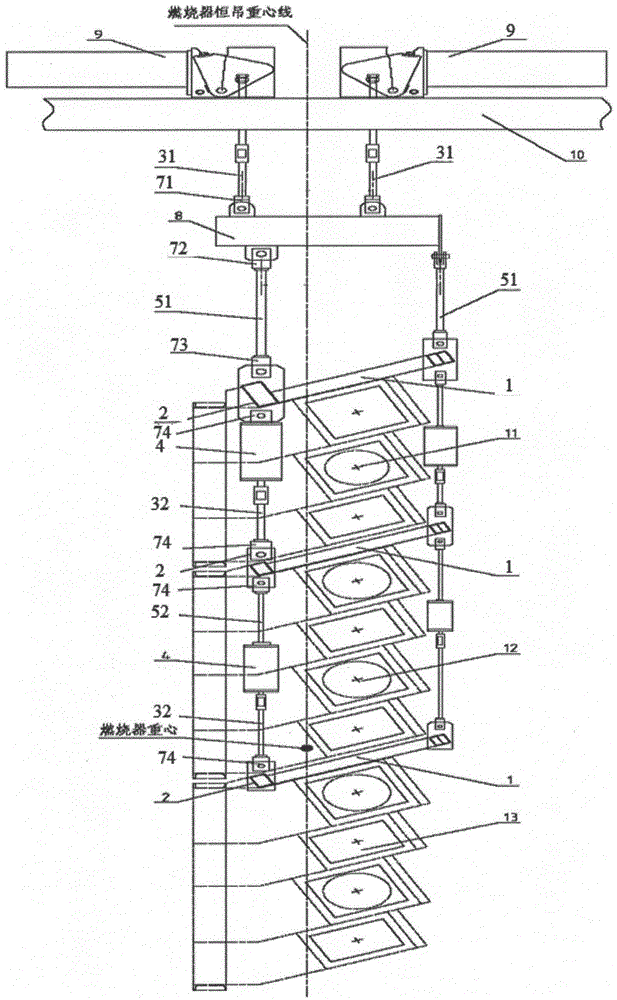

[0028] Such as figure 1 As shown, it is a schematic structural diagram of the double-constant-force spring hanger balanced suspension three-section hanger type inclination burner in Example 1, and the double constant-force spring hanger balance suspension three-section hanger type inclination burner Comprising a balance suspension beam 8, two constant force spring hangers 9 and a main burner, the main burner consists of a first group of inclination burners 11, a second group of inclination burners 12 and The third group of inclination burners 13 is formed, and the minimum distance between adjacent groups of inclination burners is 241mm. The structures of the three groups of inclination burners are slightly different, but they all form an angle of 22° with the horizontal plane.

[0029] A hanger 1 is provided on the top of each group of inclined burners. The included angle between the hanger 1 and the horizontal plane is consistent with the inclination angle of the inclination...

Embodiment 2

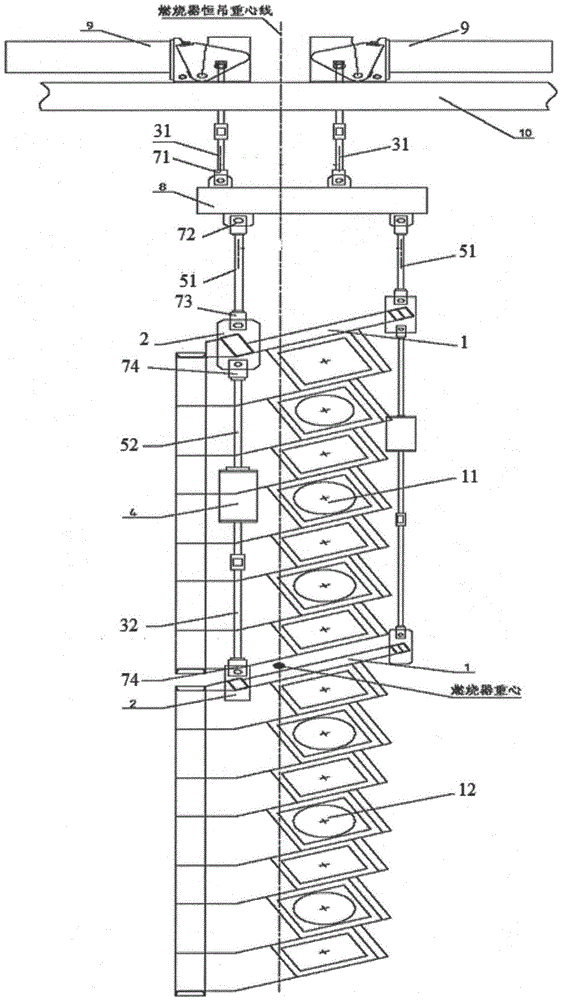

[0037] Such as figure 2 Shown is a schematic diagram of the structure of the double-constant-force spring hanger balanced suspension of the two-stage hanger-type inclination burner in Example 2. The double-constant-force spring hanger balanced suspension two-stage hanger-type inclination burner includes a balance suspension beam 8, two constant-force spring hangers 9 and a main burner, and the main burner is formed from top to bottom. The first group of oblique burners 11 and the second group of oblique burners 12 are arranged in sequence. The minimum distance between adjacent groups of oblique burners is 260mm. The structures of these two groups of oblique burners are slightly different, but they are all in line with the horizontal into a 25° angle.

[0038] A hanger 1 is provided on the top of each group of inclined burners. The included angle between the hanger 1 and the horizontal plane is consistent with the inclination angle of the inclination burner. The two constan...

Embodiment 3

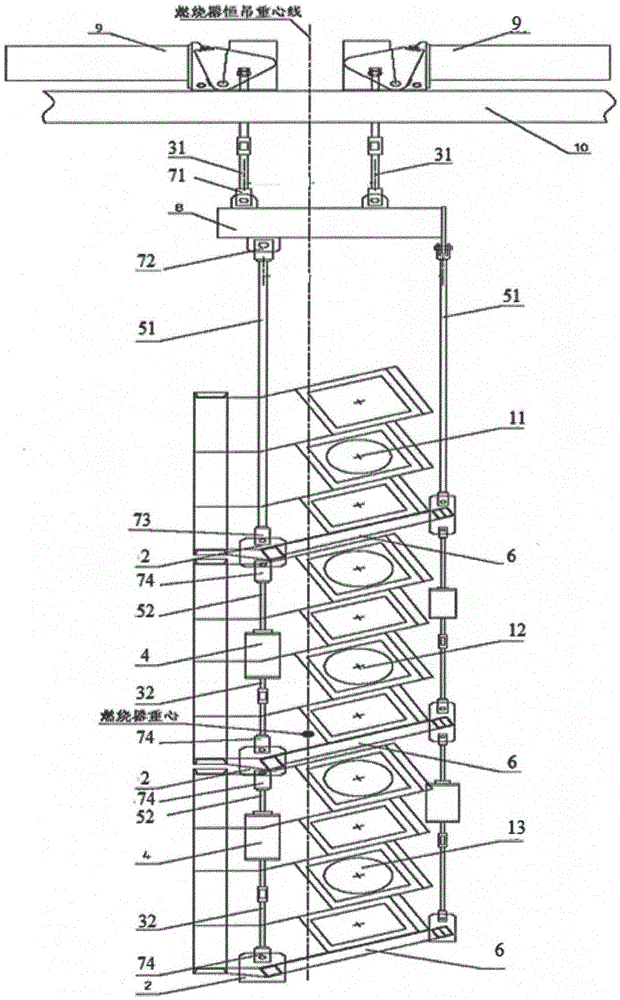

[0043] Such as image 3 As shown, it is a schematic structural diagram of a three-stage bracket-type inclination burner balancedly suspended by double constant force spring hangers in Example 3. The three-section hanger-type inclination burner with double constant-force spring hanger balance suspension includes a balance suspension beam 8, two constant-force spring hangers 9 and a main burner, and the main burner is formed from top to bottom. The first group of inclination burners 11, the second group of inclination burners 12 and the third group of inclination burners 13 arranged in sequence, the minimum distance between adjacent groups of inclination burners is 270mm, the structure of the three groups of inclination burners Slightly different, but both form an angle of 23° with the horizontal.

[0044] The bottom of each group of inclination burners is provided with a bracket 6 . The included angle between the bracket 6 and the horizontal plane is consistent with the incli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com