Automobile diode device and manufacturing method thereof

A diode and automotive technology, used in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve problems such as reduced impact resistance and reliability, increased probability of contamination, and infiltration into plastic packages, and achieves consistency. Good, guaranteed reflow resistance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiments.

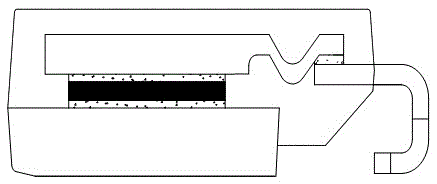

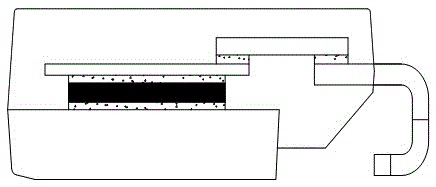

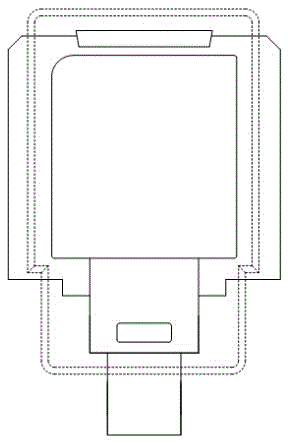

[0031] A diode device for automobiles in the present invention includes a lead frame 1, a diode chip 4, and an inner connecting piece 10 arranged in sequence. The lead frame 1 is composed of a lead frame pin 2 and a lead frame bottom plate 3. The diode chip 4 It is arranged on the lead frame bottom plate 3, and the diode chip 4 and the lead frame bottom plate 3 are connected by electrode pads A6. The inner connecting piece 10 is composed of an inner connecting piece body 5 and an inner connecting piece pin 7, so The inner connecting piece 10 is a special-shaped belt integral straight structure with upper and lower through holes 8, and the through holes 8 are on the inner connecting piece pins and above the lead frame pins 2, and the through holes 8 are A pin solder block 9 is provided, the inner connecting sheet main body 5 is arranged on the diode chip 4, and the inner connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com