LED chip electrode and manufacture method thereof

A technology of LED chip and manufacturing method, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of poor lateral expansion ability of LED chip current and the influence of LED chip luminous brightness, so as to improve horizontal expansion ability and luminous brightness , The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

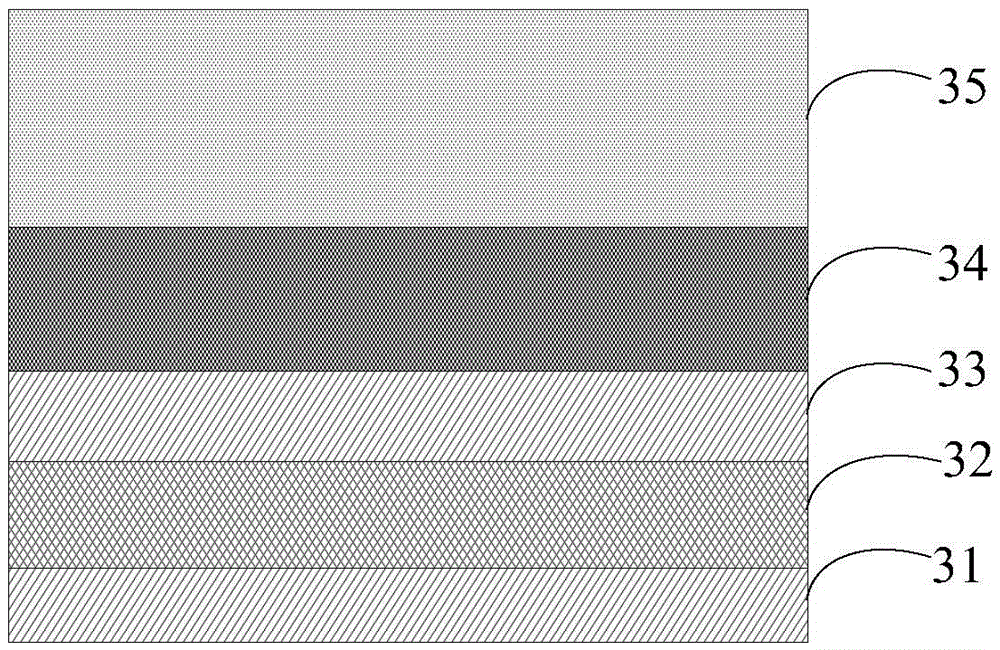

[0044] ginseng image 3 As shown, in a specific embodiment of the present invention, the LED chip electrodes sequentially include:

[0045] The first metal adhesion layer 31 is used to adhere to the semiconductor epitaxial layer and form an ohmic contact, its material is Cr, and its thickness is 5-150 Å;

[0046] The metal reflective layer 32 is used to reflect the light in the light-emitting area under the electrode to improve the luminous brightness of the LED chip. The material is Al and the thickness is 1000-3000 Å;

[0047] The second metal adhesion layer 33 is used to adhere the metal reflective layer 32 and the metal protection layer 34, and its material is Cr with a thickness of 50-500 Å;

[0048] The metal protection layer 34 is used to protect the metal reflective layer 32 and the second metal adhesion layer 33 below, and its material is Ti with a thickness of 1000-3000 Å;

[0049] The metal wiring layer 35 is used for welding the electrodes and external devices th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com