Wind power cable clamp hanger

A technology of cable clamps and spreaders, which is applied in the directions of cable laying equipment, load hanging components, transportation and packaging, etc. It can solve problems such as piercing into the cable insulation layer, wire mesh sheath drawing, and cable insulation damage, etc., to achieve stability The effect of fixing cables, enhancing heat dissipation, and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

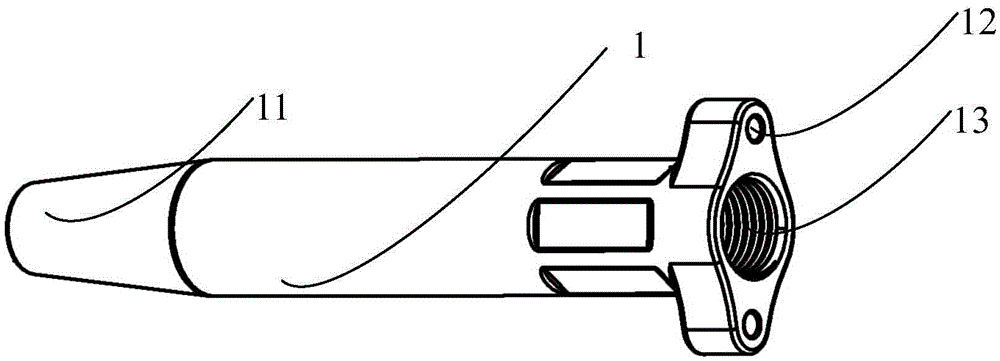

[0030] Such as Figure 1-Figure 6 As shown, the components of the wind power cable clamp sling include a cable sling body 1, a cable protective insulator 2,

[0031] Cable protection insulator 3, cable pre-tightening hollow bolt 4, cable pre-tightening hollow bolt positioning ring 5 and cable sling belt bolt ring 6.

[0032] Such as figure 1 As shown, the cable spreader body 1 is a round tube with an inverted conical lower end, a flange on the upper end, and a thread 13 inside, which is locked and combined with the external thread of the cable pre-tightening hollow bolt 41; the flange is provided with symmetrical longitudinal Through the hole 12, the cable hanger belt bolt ring 6 passes through the circular through hole and is combined with the cable hanger body 1.

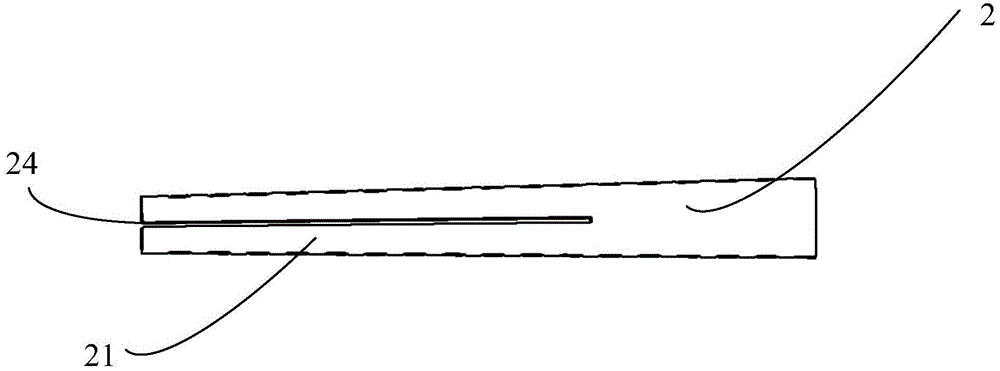

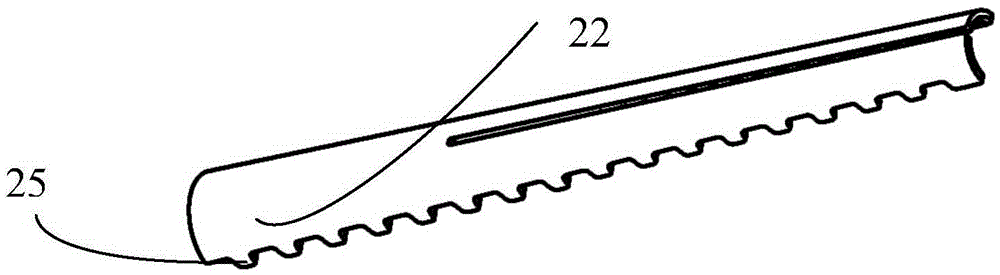

[0033] The cable protective insulator 2 provided in the cable spreader body 1 is in the shape of an inverted cone, and fits with the lower end cone 11 of the cable spreader body 1; Figure 2-3 As shown, the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com