A transmission screw rod of carbon fiber composite material

A technology of carbon fiber materials and composite materials, applied in transmission devices, belts/chains/gears, mechanical equipment, etc., can solve problems such as no technical descriptions or reports, no data collected, etc., to ensure smoothness and high reliability, Lightweight and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

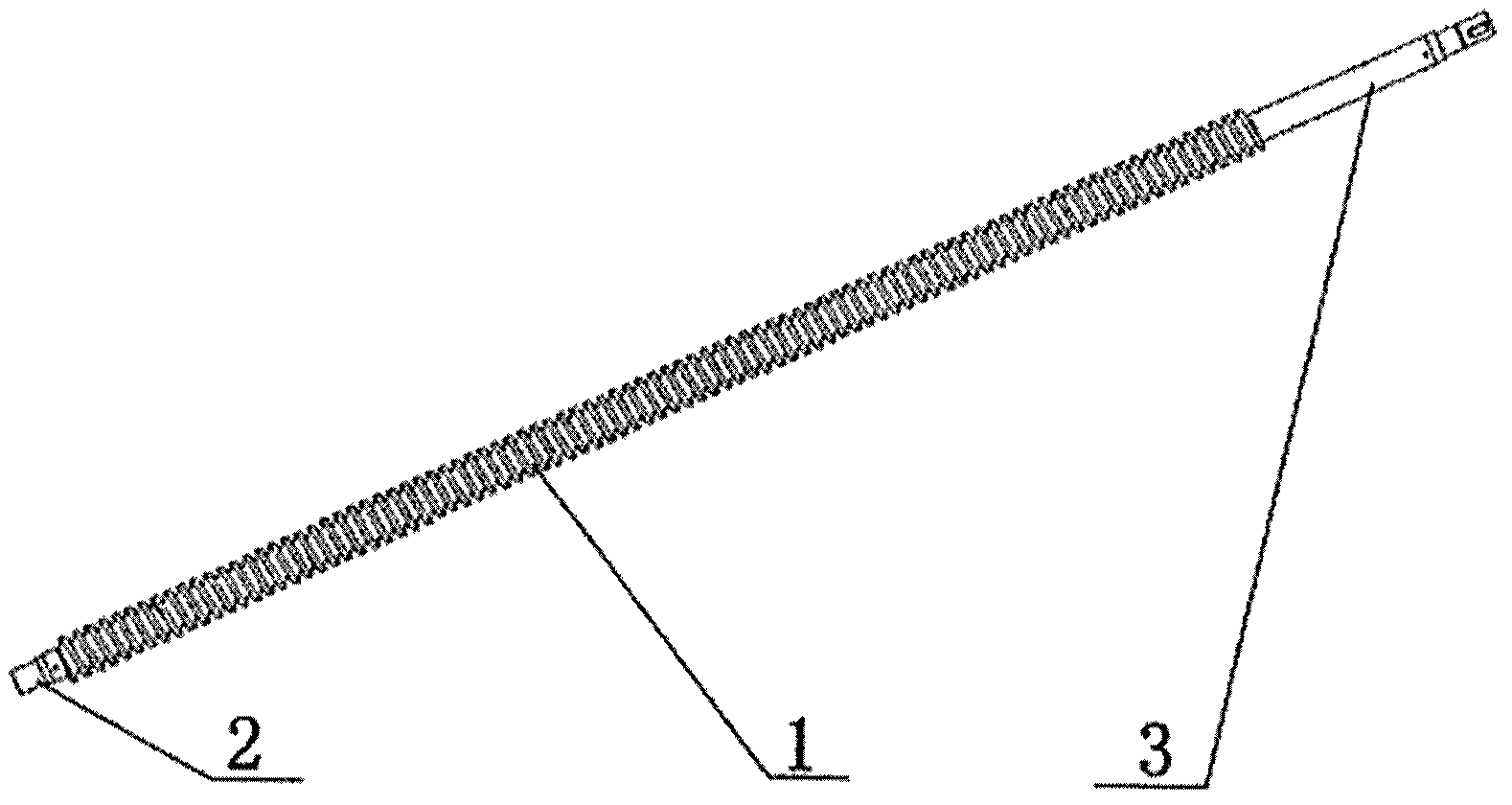

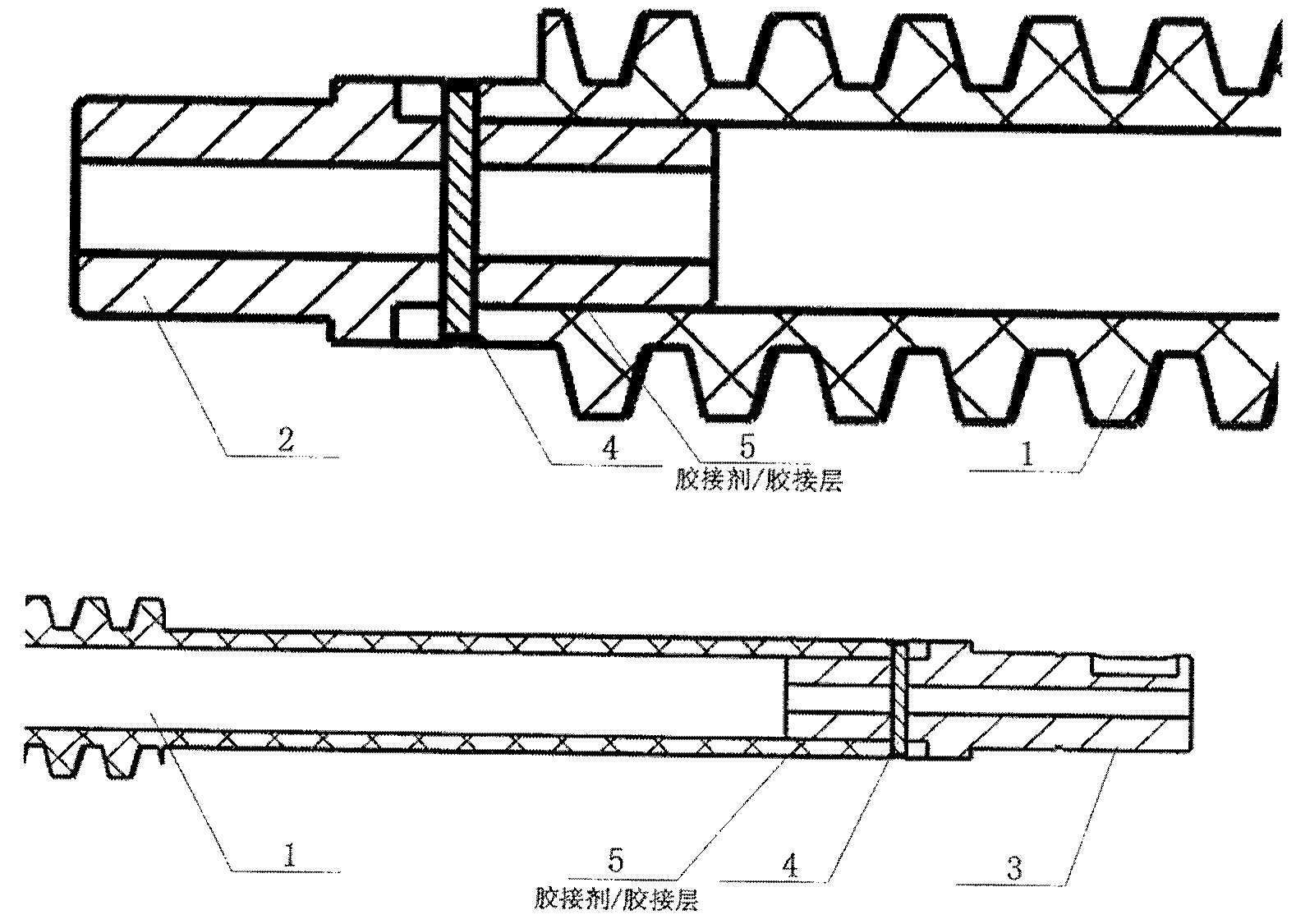

[0013] attached figure 1 and figure 2 Shown is the axonometric view of the transmission screw rod structure of the carbon fiber composite material of the present invention. It can be seen in the illustration that the screw rod is composed of the screw rod main body [1], joint 1 [2], joint 2 [3], pin [4], glue Adhesive [5], the main body of the screw rod is made of full carbon fiber material M55J, on this basis, the composite material is reinforced, and its molding adopts mature processes such as molding and winding to complete the molding of the screw rod. The transmission part adopts trapezoidal screw teeth, and double-start threads are adopted at both ends of the screw rod. The nominal diameter of the thread is not less than 26mm, the pitch is 8mm, and the lead is not greater than 16mm. The joint is connected to the main body of the carbon fiber screw rod 1; the adhesive 5 is selected from J133 structural glue, which is used for the connection between the joint and the mai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thread length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com