Air filter plate manufactured by sand and method for manufacturing filter plate through sand

An air filtration material and sand technology, applied in filtration and separation, membrane filters, separation methods, etc., can solve the problems of uncleaning, clogging, short service cycle, etc., achieve excellent filtration effect, reduce use cost, and increase service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

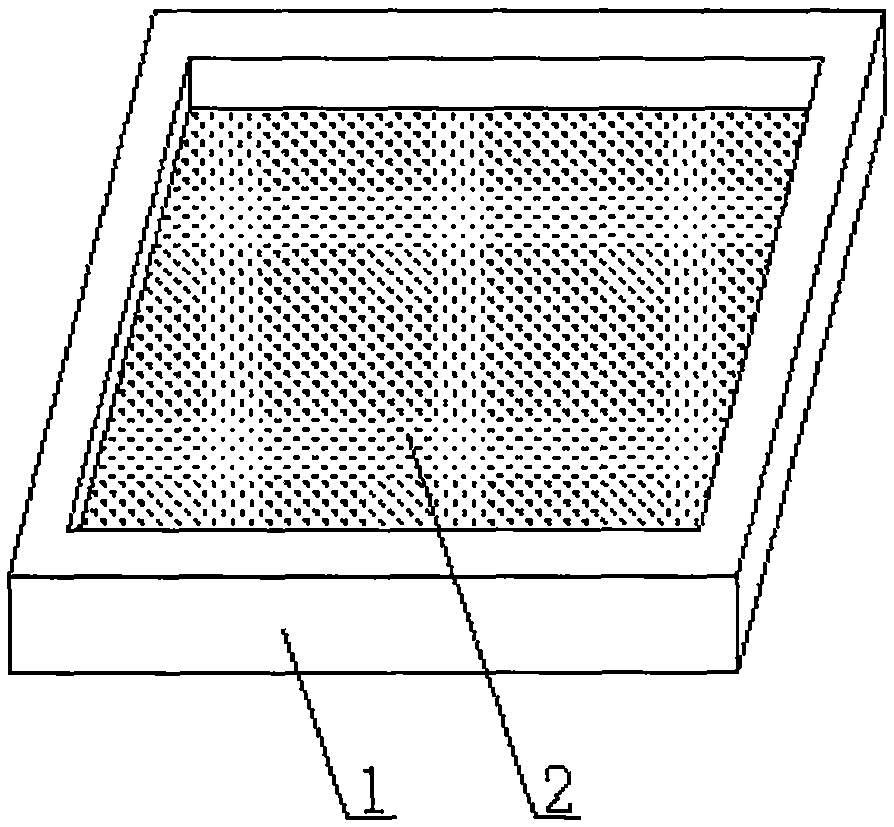

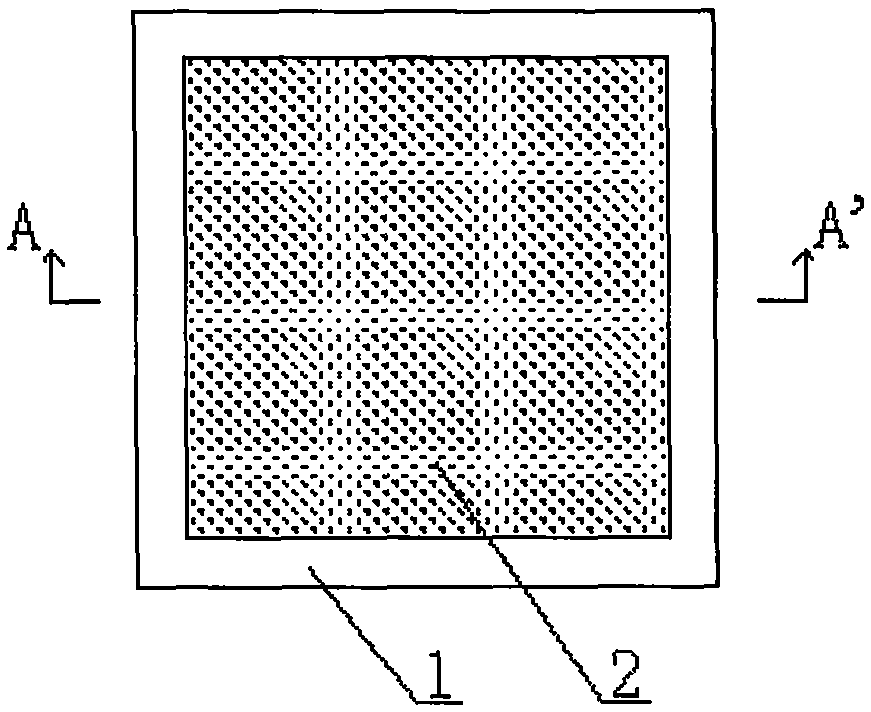

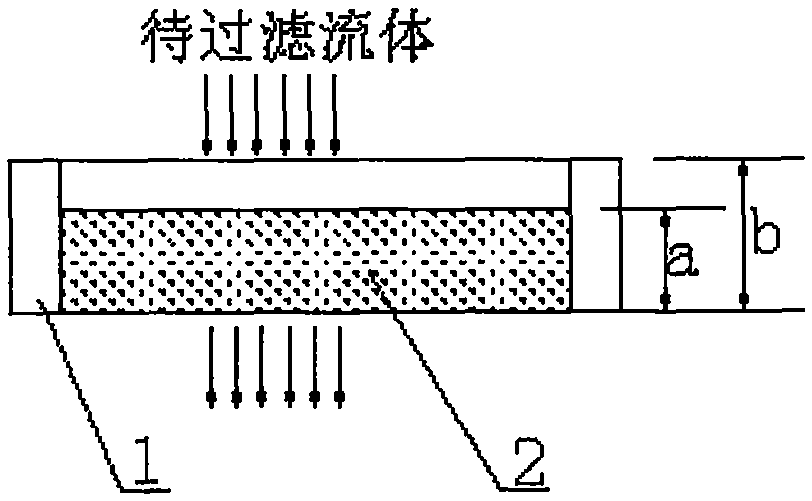

[0038] Such as Figure 1-3 As shown, it is a preferred embodiment of the present invention. This embodiment relates to a sand air filter plate for filtering fluid to be filtered. The filter plate includes a filter body 2 and a frame 1 surrounding the filter body 2 . In this embodiment, the filter body 2 is formed by pressing sand.

[0039] The frame 1 is not provided with top and bottom surfaces. The thickness a of each position of the filter body 2 is equal, and a is less than or equal to the thickness b of the frame 1 . In this embodiment, the thickness a of the filter body 2 is smaller than the thickness b of the frame 1 . Further, the incoming flow surface of the filter body 2 is lower than the frame 1 , and the outgoing flow surface of the filter body 2 is equal to the frame 1 . Further, the thickness a of the filter body 2 is 2 mm.

[0040] A method of utilizing sand to manufacture the filter plate, the specific steps are as follows:

[0041] S01: The frame 1 withou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com