Diversion nozzle material pull structure

A material handle and drainage groove technology, which is applied in the field of die-casting molds, can solve problems such as deformation, and achieve the effects of preventing deformation, firm and reliable connection, and stable molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

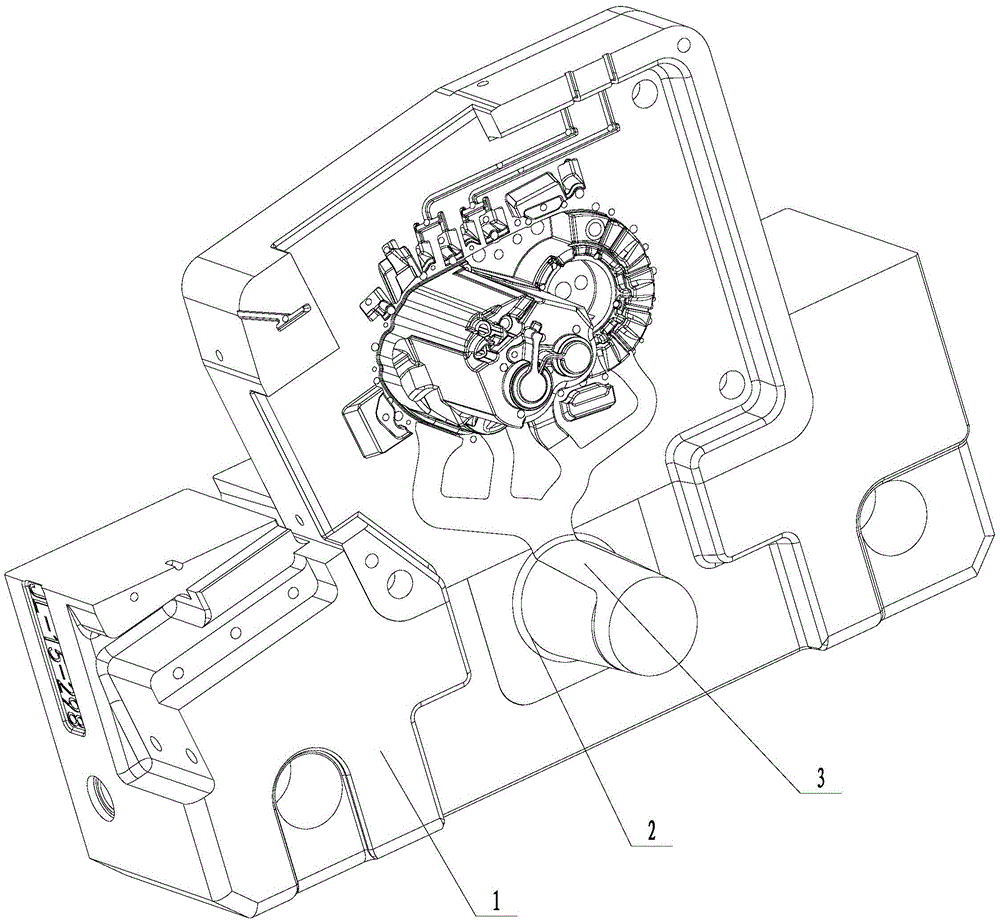

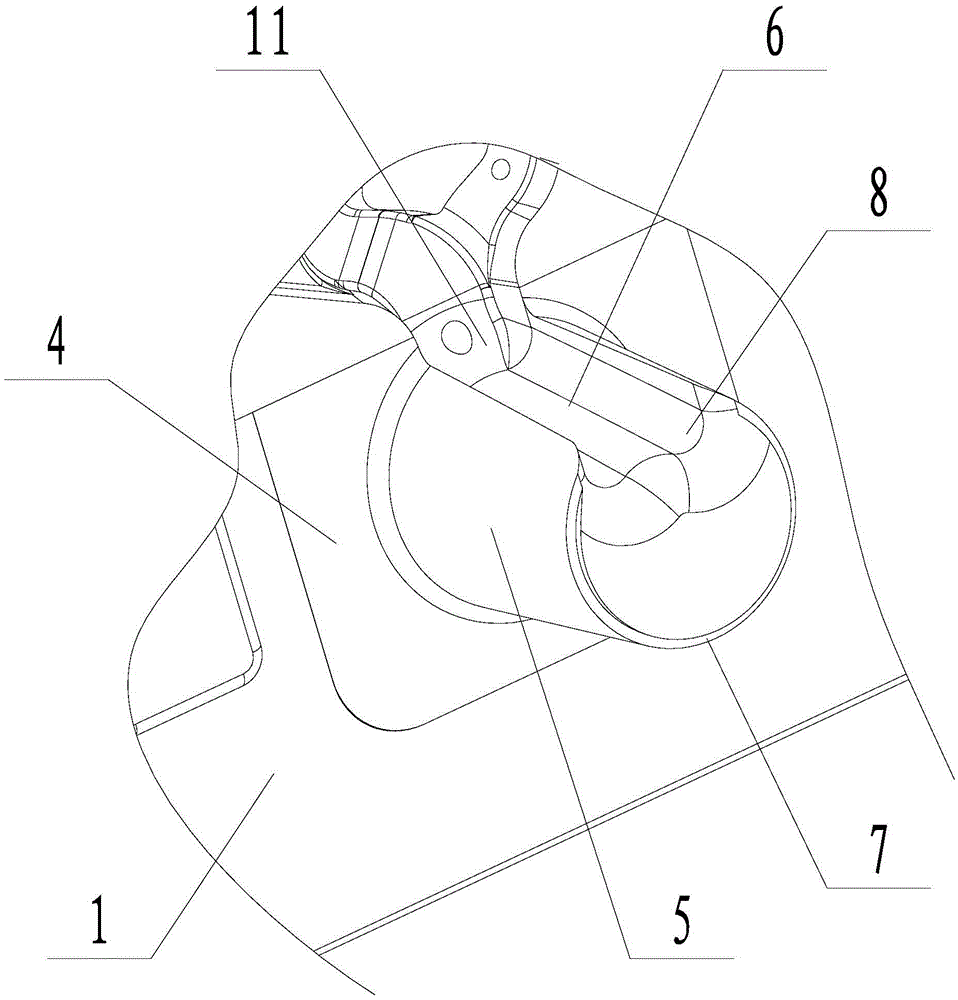

[0021] Embodiment 1: A kind of shunt nozzle pulling material structure (see attached figure 1 , attached figure 2 ), including the fixed mold frame 1, the shunt nozzle 2 installed on the fixed mold frame, the product material handle 3 is arranged between the shunt nozzle and the fixed mold frame, and the shunt nozzle includes a base 4 and a shunt nozzle arranged on the base The body 5 has a rectangular base, and the diverter nozzle is arranged vertically on the base. The body of the diverter nozzle is in the shape of a circular platform with a small upper part and a larger lower part. There is a drainage groove 6 on the side wall of the diverter nozzle body. There is a circle of holding groove 7 on the edge of the upper surface of the diversion nozzle body. Both ends of the holding groove are connected with the drainage groove. , the angle between the sides and the bottom of the holding groove is 88-92 degrees. The axial height of the holding groove from the upper surface o...

Embodiment 2

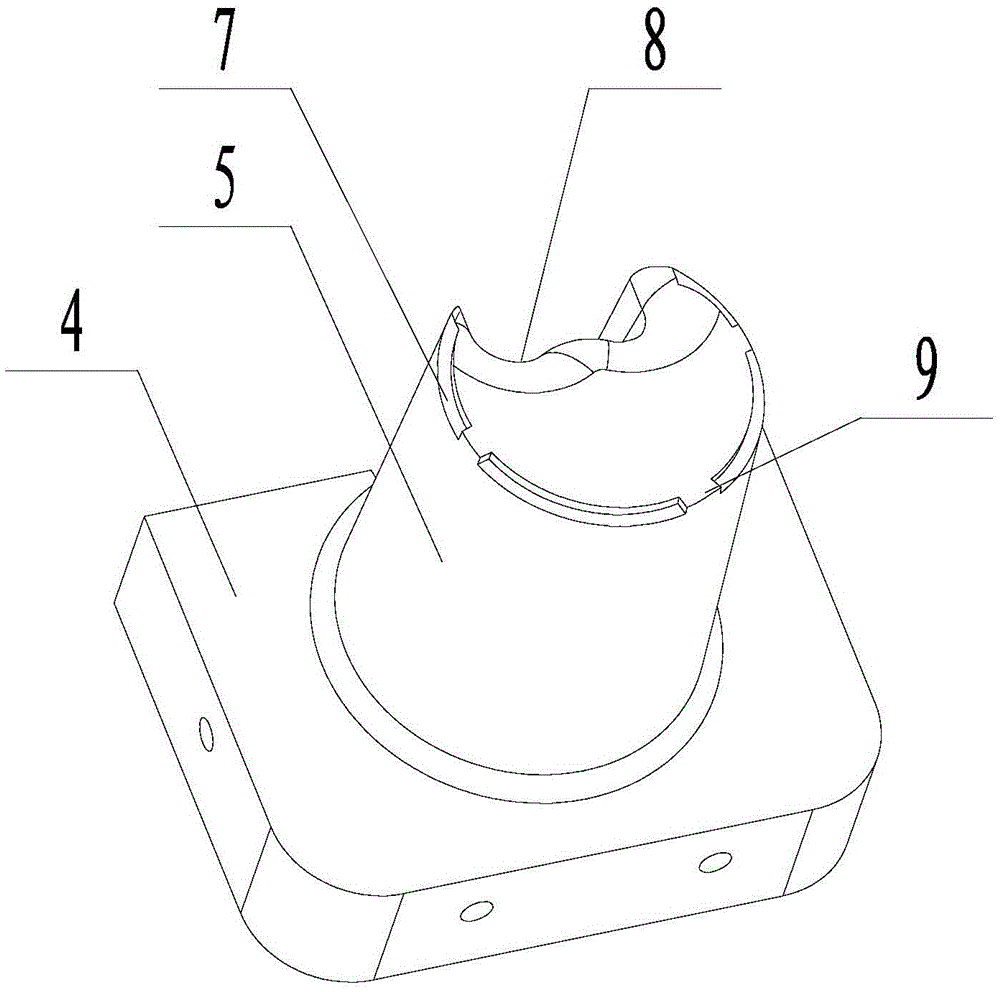

[0023] Embodiment 2: A kind of shunt nozzle pulling material structure (see attached image 3 ), including the fixed mold frame 1, the shunt nozzle 2 installed on the fixed mold frame, the product material handle 3 is arranged between the shunt nozzle and the fixed mold frame, and the shunt nozzle includes a base 4 and a shunt nozzle arranged on the base The body 5 has a rectangular base, and the diverter nozzle is arranged vertically on the base. The body of the diverter nozzle is in the shape of a circular platform with a small upper part and a larger lower part. There is a drainage groove 6 on the side wall of the diverter nozzle body. There is a circle of holding groove 7 on the edge of the upper surface of the diversion nozzle body. Both ends of the holding groove are connected with the drainage groove. , the angle between the sides and the bottom of the holding groove is 88-92 degrees. The axial height of the holding groove from the upper surface of the diverter body to...

Embodiment 3

[0024] Embodiment 3: A kind of shunt nozzle pulling material structure (see attached image 3 ), including the fixed mold frame 1, the shunt nozzle 2 installed on the fixed mold frame, the product material handle 3 is arranged between the shunt nozzle and the fixed mold frame, and the shunt nozzle includes a base 4 and a shunt nozzle arranged on the base The body 5 has a rectangular base, and the diverter nozzle is arranged vertically on the base. The body of the diverter nozzle is in the shape of a circular platform with a small upper part and a larger lower part. There is a drainage groove 6 on the side wall of the diverter nozzle body. There is a circle of holding groove 7 on the edge of the upper surface of the diversion nozzle body. Both ends of the holding groove are connected with the drainage groove. , the angle between the sides and the bottom of the holding groove is 88-92 degrees. The axial height of the holding groove from the upper surface of the diverter body to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com