Method for processing hole by laser

A laser processing and laser technology, used in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of poor roundness and cross-section effect, burrs block small holes, and the cutting section is not rough enough and smooth, etc., to improve the processing quality. efficiency, improve processing efficiency, and avoid the effect of poor processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings. Preferred embodiments of the invention are shown in the accompanying drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein. On the contrary, the purpose of providing these embodiments is to make the disclosure of the present invention more thorough and comprehensive.

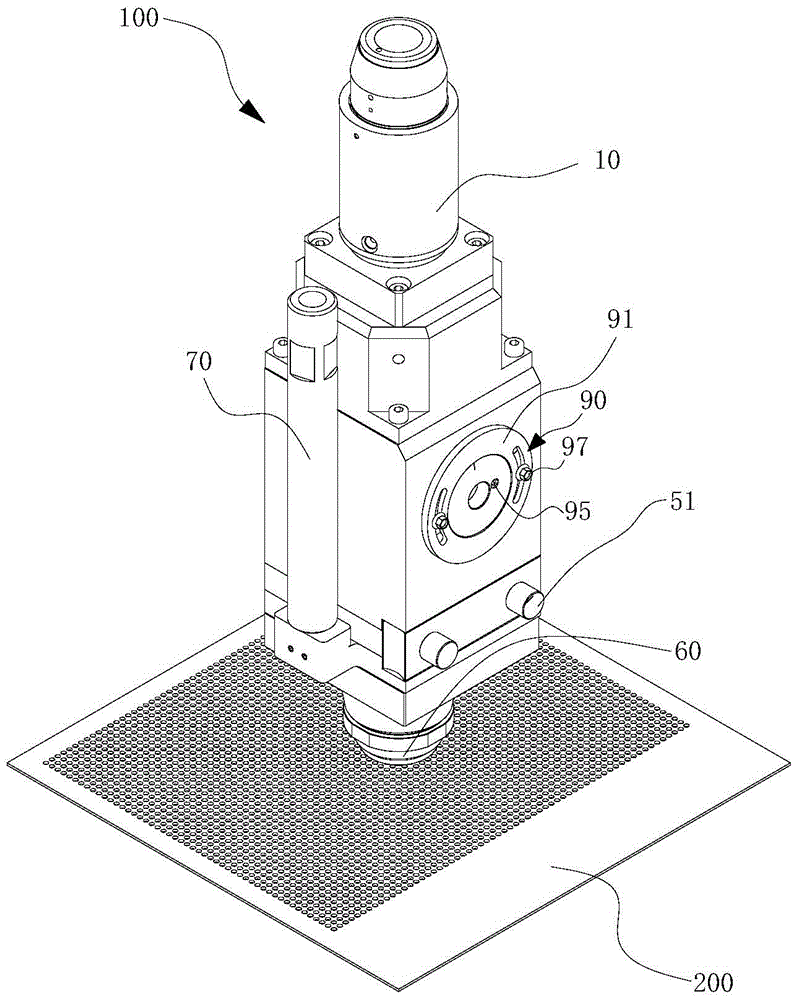

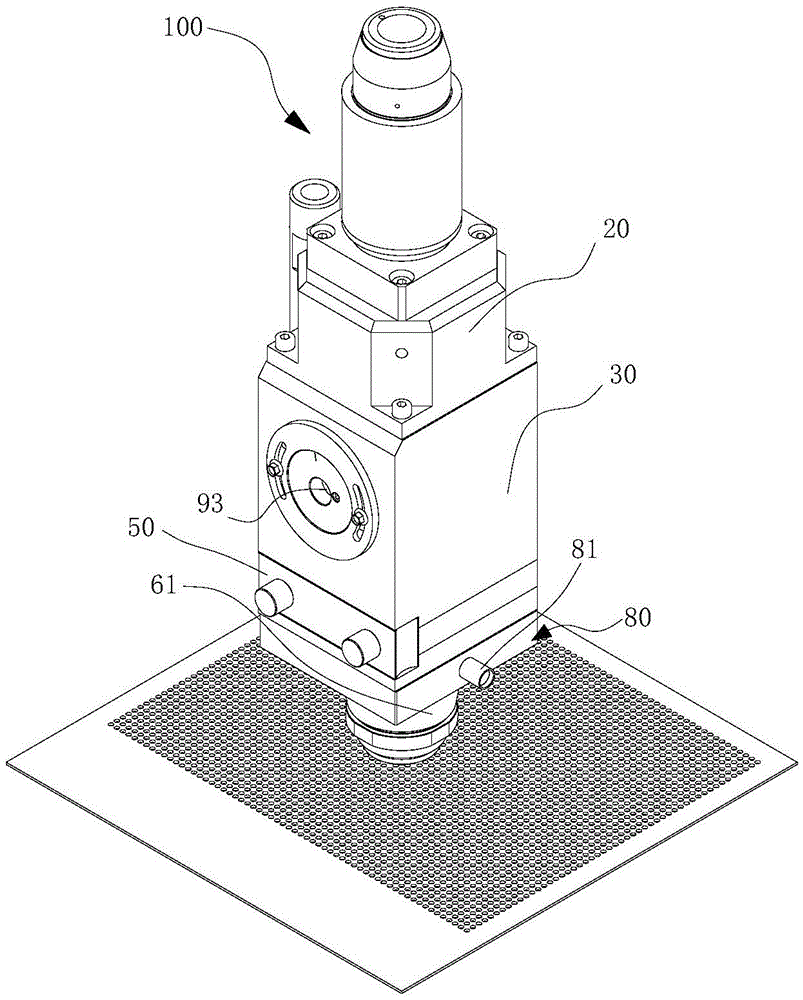

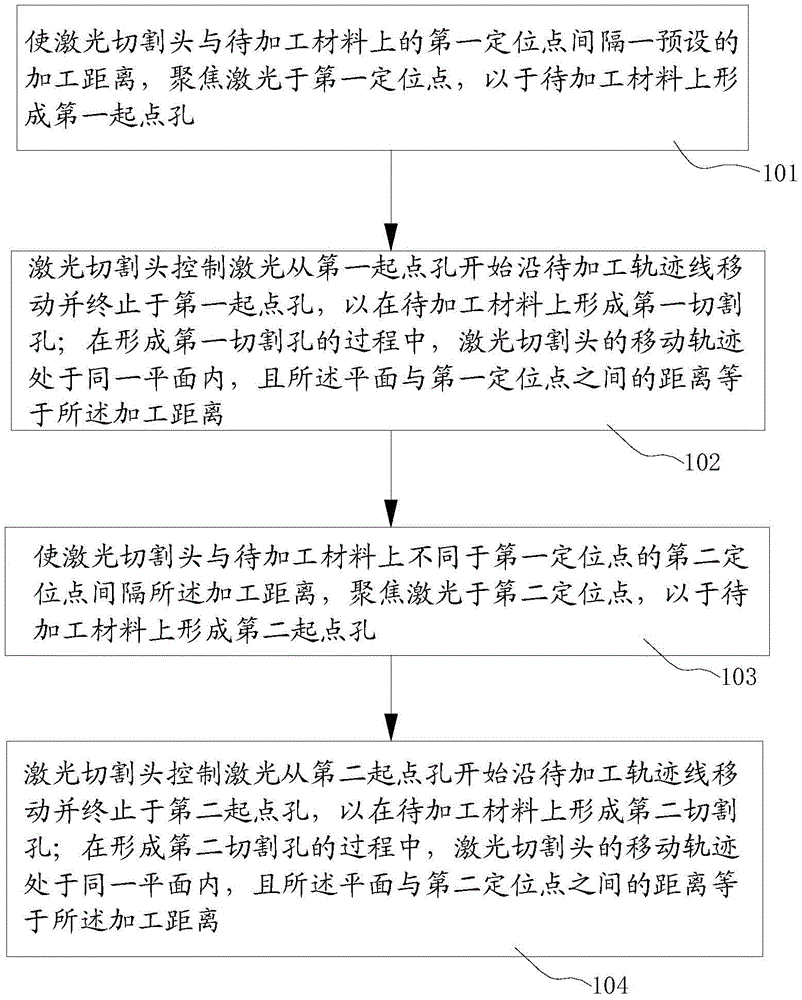

[0022] see figure 1 and figure 2 , the method for adopting laser machining hole of one embodiment, the laser cutting head 100 that it adopts comprises laser connector 10, collimating mirror base 20, focusing mirror base 30, protective mirror base 50, nozzle 60, air pipe joint 70, follow-up assembly 80 and focus adjustment assembly 90. Laser connector 10, collimator mirror holder 20, focusing mirror holder 30, protection mirror holder 50, nozzle 60 are conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com