A production process of welding chair back iron platform

A production process and seat back technology, which is applied in the field of welding seat back iron table production process, can solve the problems of equipment impact, long downtime and calibration time, restricting the development of seat welding production technology, and high clamping failure rate and scrap rate. To achieve the effect of reducing manual clamping errors, reducing equipment downtime and calibration time, and reducing the rate of defective clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

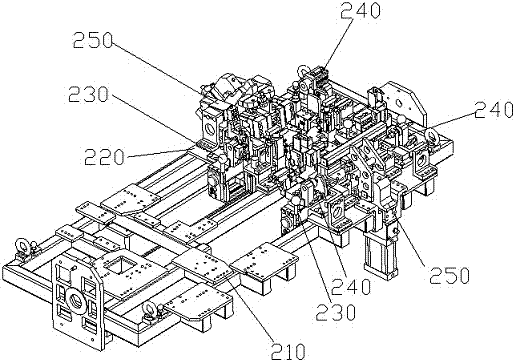

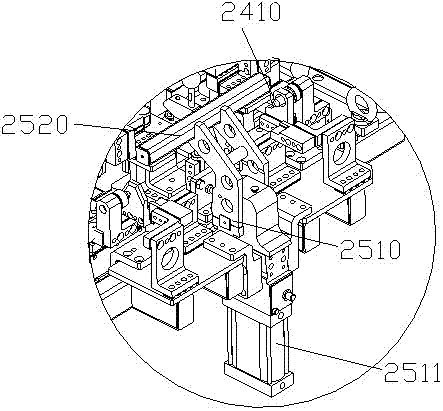

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

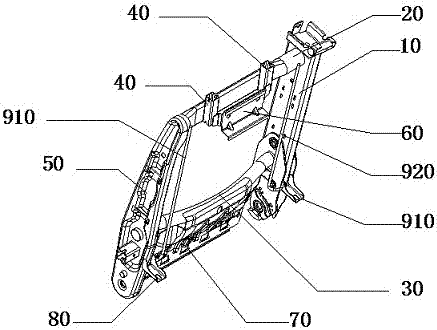

[0024] Such as figure 1 As shown, it is the overall structure of the molded car seat back in this embodiment. The car seat back frame mainly includes the upper pipe frame and the middle horizontal pipe frame, the back side square pipe and the pillow pipe, the support frame line, and the back panel fixing bracket. .

[0025] It mainly includes the following procedures:

[0026] a. Stamping forming: Stamping and forming the plates to form side panels, lower back panels, and fixing brackets for back panels, stamping and forming round tube materials into upper tube racks and mid-horizontal tube racks, and cutting and forming square tube raw materials into Dorsal square tube and pillow tube; support frame line adopts stamping or forging molding.

[0027] b. Riveting operation: Put the pillow conduit of the back side square tube workpiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com