Management device and management method

A technology for managing and managing yarn bobbins, applied in the field of managing and managing devices, can solve the problems of limited processing capacity of yarn bobbin types, complex structure of managing and managing machines, single managing and managing functions, etc., and achieves diversified management types, simple and compact structure, Manage powerful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

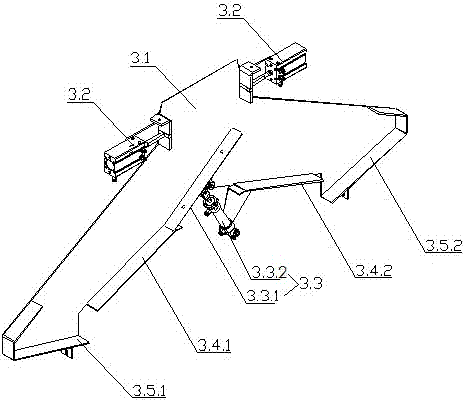

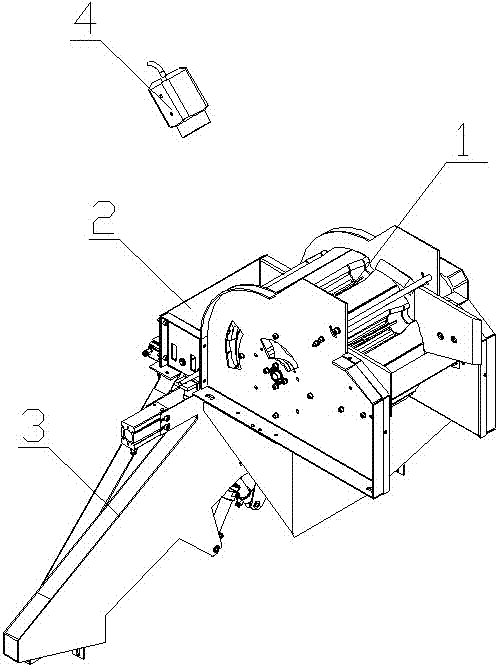

[0036] See Figure 1~Figure 12 , The present invention relates to a management device, which includes a transportation management mechanism 1, a primary management mechanism 2, a secondary management mechanism 3, and a detection control mechanism. The discharge port of the transportation management mechanism 1 and the primary management mechanism 2 The inlet of the first-level branching mechanism 2 is connected with the inlet of the second-level branching mechanism 3.

[0037] The pipe transport mechanism 1 includes a pipe transport mechanism support 1.1. The pipe transport mechanism support 1.1 is provided with a pipe transport roller 1.2. The pipe transport mechanism support 1.1 at the feed port of the pipe transport roller 1.2 is provided with a piece of obliquely downward pointing transport. The receiving plate 1.3 of the tube roller 1.2, the tube transport mechanism support 1.1 is also provided with a tube transport motor 1.4 that drives the tube transport roller 1.2, the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com