Automatic weighing and feeding device

A technology of gravimetric feeding and feeding device, which is used in loading/unloading, transportation and packaging, conveyors, etc., to achieve the effects of high equipment utilization, improved quality, and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

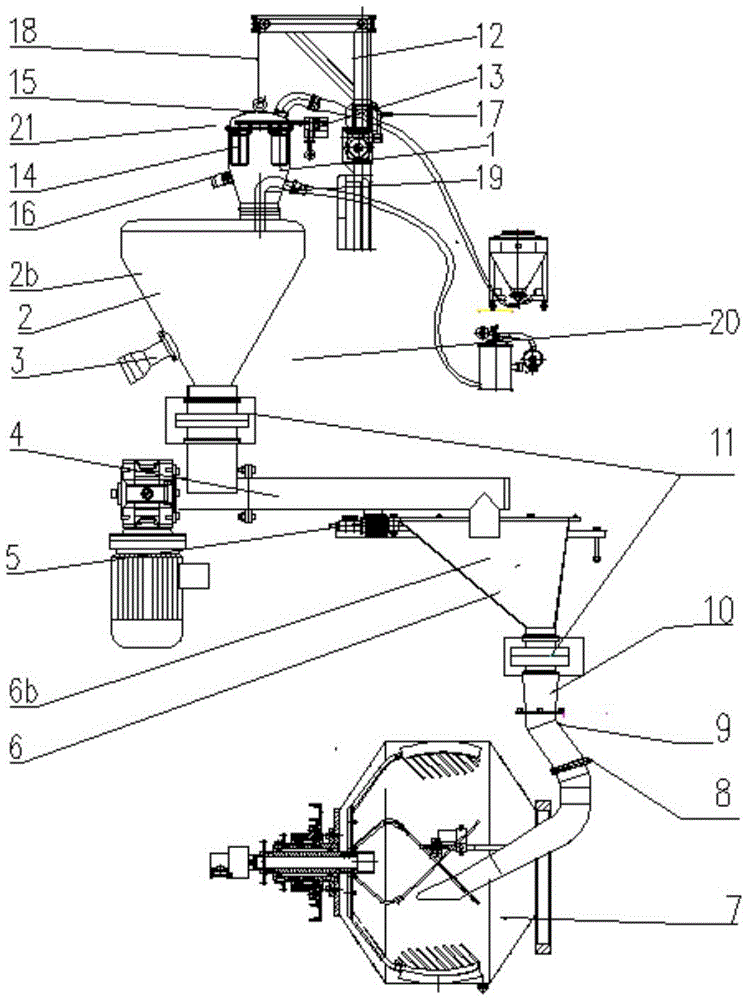

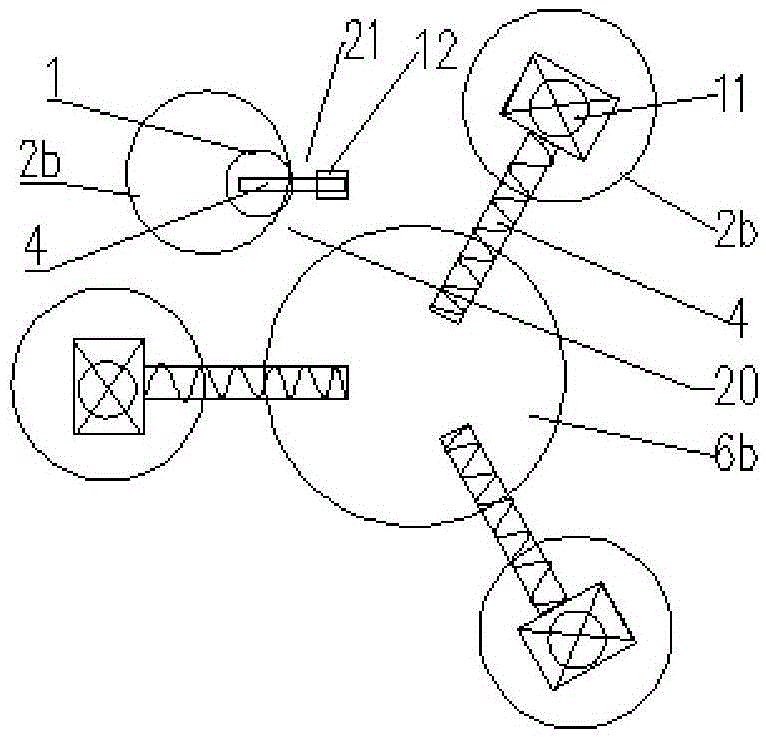

[0018] In order to better understand the technical solution of the automatic weighing feeding device of the present invention, the self-weighing weighing feeding device will be further described through examples and in conjunction with the accompanying drawings.

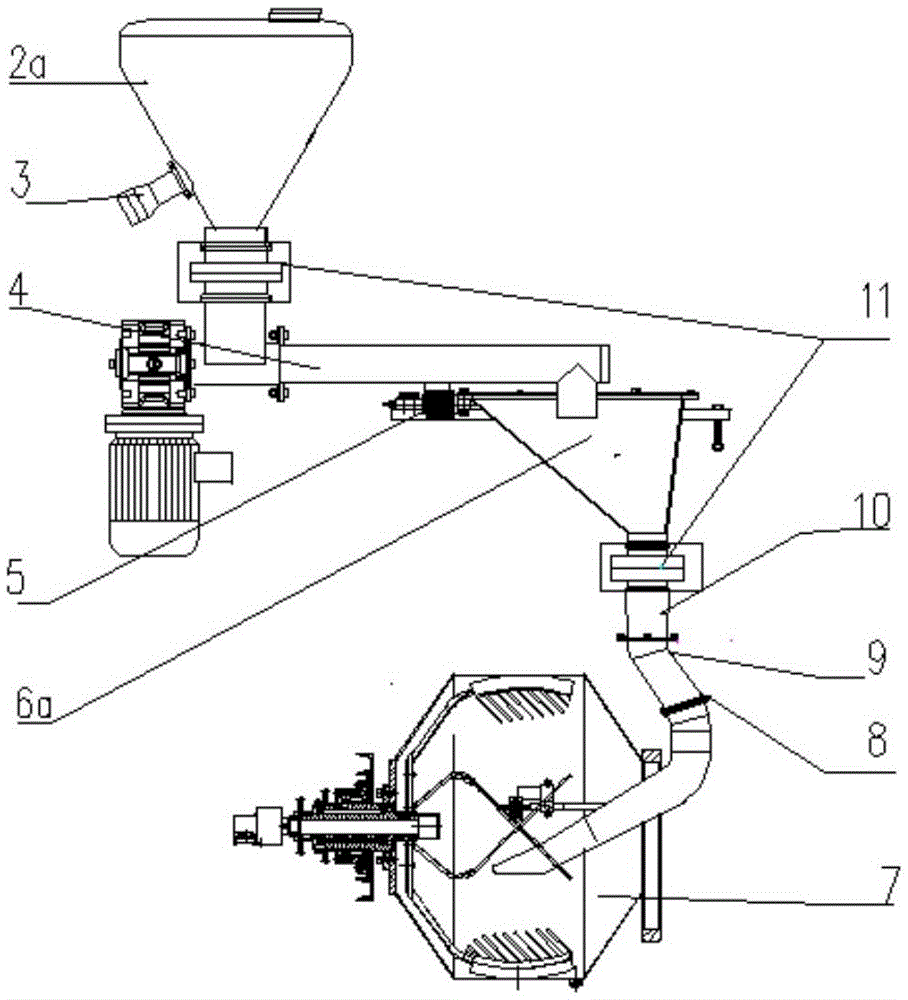

[0019] Such as figure 1 shown. The automatic weighing feeding device of the present invention comprises hopper 6, corresponding feeding device 20 and controller etc., and its feeding device comprises storage tank 2, and hopper 6 is the common hopper 6a without weighing sensor, and storage tank 2 These are common storage tanks 2a and corresponding conveyors. Its conveyor is a screw conveyor 4 . The storage tank 2a is connected to the ordinary hopper 6a through its screw feeder 4, and the screw feeder 4 is connected to the controller with an electrical signal, and the controller is used to measure the hopper 2a accurately through the screw feeder 4. Automatic dosing. When the material is metered and conveyed, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com