Working method of submersible type aluminum-gallium alloy hydrogen manufacturing unit

A technology of aluminum-gallium alloy and hydrogen production device, which is applied in the production of hydrogen, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

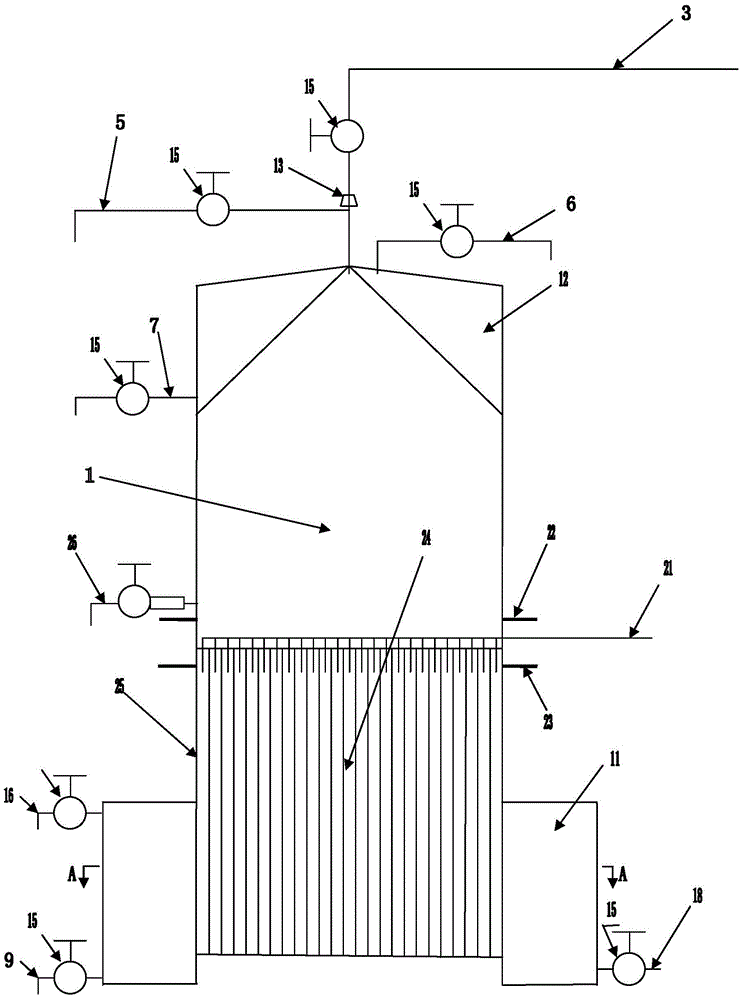

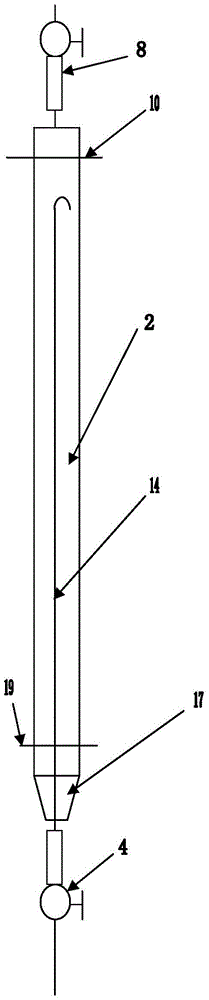

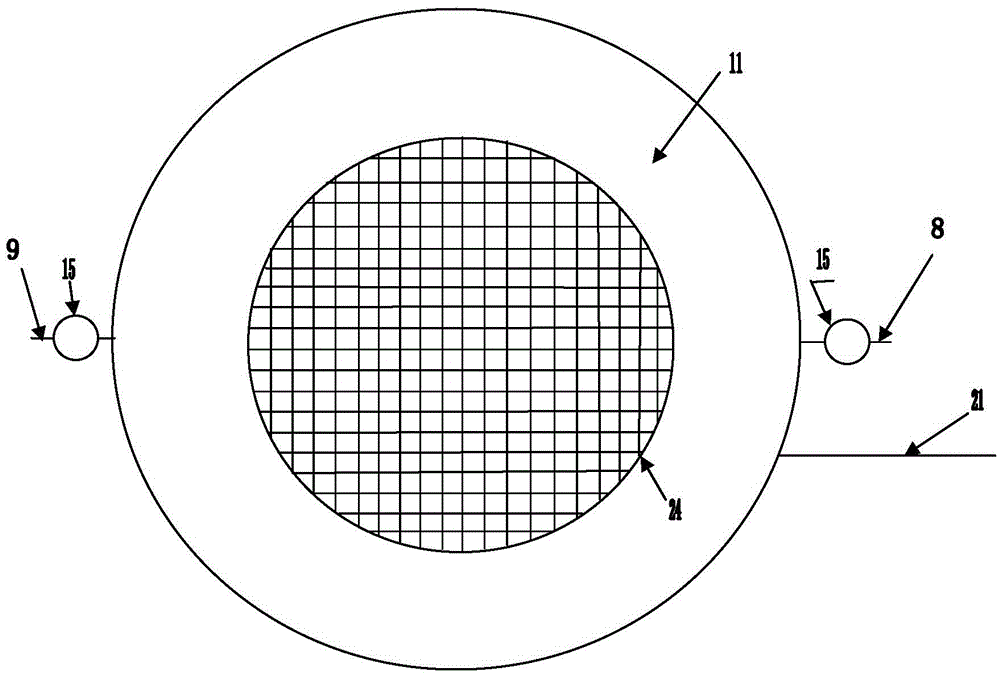

[0012] The submersible aluminum-gallium alloy hydrogen production device consists of cone-top barrel 1, aluminum-gallium alloy hydrogen generating rod 2, hydrogen gas collection pipe 3, seawater and hydrogen flow transmitter regulating valve and hydrogen alarm 4, cone-top barrel air discharge Pipe 5, upper pressurized water tank air discharge pipe 6, upper pressurized water tank drain pipe 7, hydrogen flow transmitter regulating valve 8, lower pressurized water tank drain pipe 9, hydrogen end flange connection tray 10, lower pressurized water tank 11 , upper pressure water tank 12, different diameter pipe water identification transmitter 13, sea water inlet pipe 14, instrument-controlled pneumatic valve 15, lower pressure water tank air discharge pipe 16, self-centering different diameter pipe 17, lower pressure water tank inlet Gas pipe 18, sea water inlet flange connection tray 19, cone top and barrel connection flange 20, signal and power cable 21, cone top barrel connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com