Method using high bauxite crushed aggregates to produce and prepare sintered alumina

A high-alumina bauxite and sintered corundum technology is applied in the field of producing sintered corundum by using high-alumina bauxite scraps to achieve low cost, controllability and improved resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

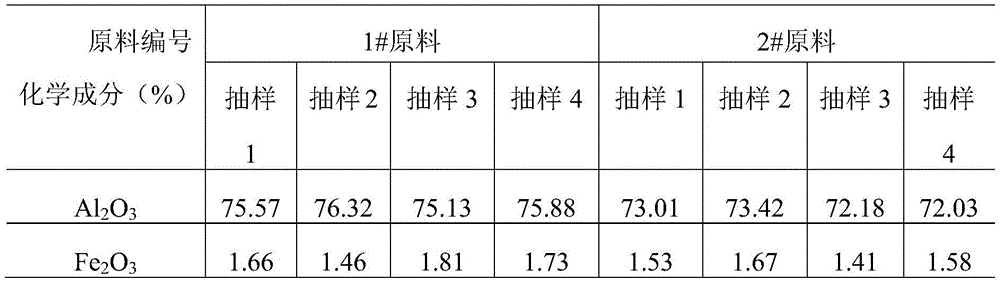

[0026] Two kinds of extra-grade refractory bauxite raw materials are used as raw materials, and they are sampled during crushing. The composition is shown in Table 1 below:

[0027] The production scale is 100t, and the production process is as follows:

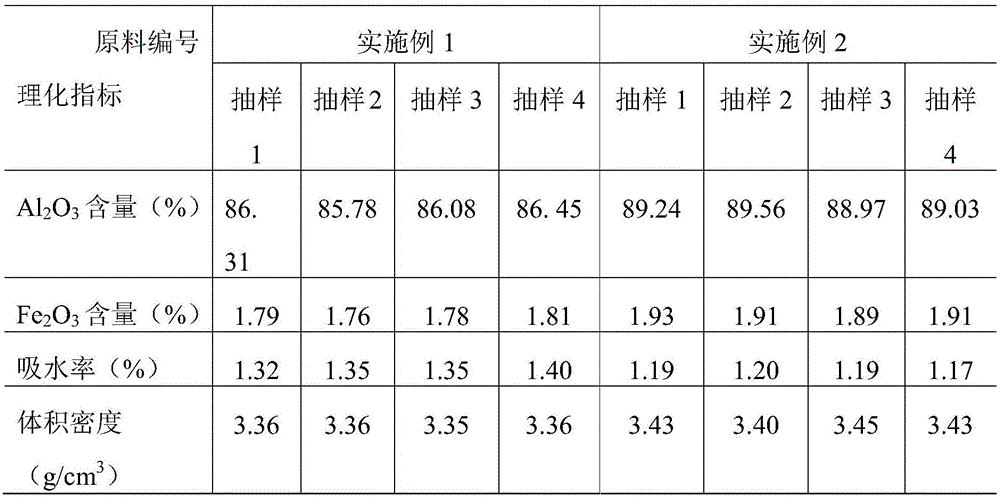

[0028] The two kinds of raw materials are crushed into granules of ≤5mm, and then uniformly mixed in the three-dimensional homogenization equipment, and then put into two raw material bins respectively; using online continuous detection and automatic batching, the system sets Al 2 o 3 The mass percentage is 86%; the material prepared according to the automatic system is transported evenly into the ball milling equipment through the belt, the ball milling is 12 hours, the particle size is 200 mesh, and the passing rate is 91%; after the slurry is iron-removed; after being dried and granulated by spray drying equipment The moisture content of the product is 6.5%; it is automatically loaded into the car after being pressed by a...

Embodiment 2

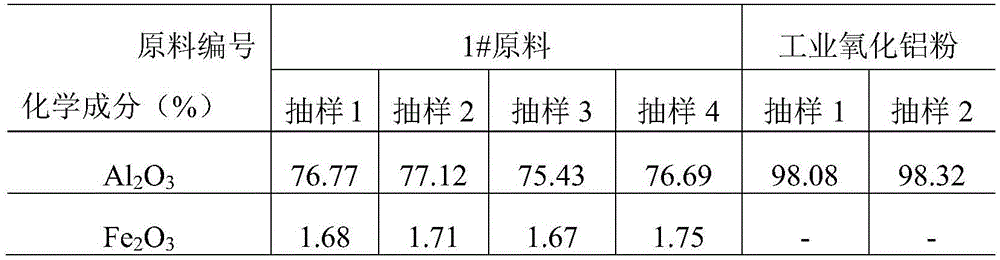

[0033] Super-grade refractory bauxite raw material scraps supplemented with alumina powder are used as raw materials. The scraps are randomly inspected when they are crushed. The alumina powder is inspected at the factory. Its composition is shown in Table 2 below:

[0034] The production scale is 100 tons, and the production process is as follows:

[0035] Crumble the raw materials into granules ≤ 5mm, mix them evenly in the three-dimensional homogenizer, and then transport them to the raw material bin, and transport the alumina powder to another raw material bin; use continuous online detection and automatic batching, and the system sets Al 2 o 3 The mass percentage is 89%; the material prepared according to the automatic system is transported evenly into the ball mill through the belt, the ball mill is 14 hours, the particle size is 200 mesh, and the pass rate is 93%. The moisture content of the product is 5.8%; it is automatically loaded into the car after being pressed b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com