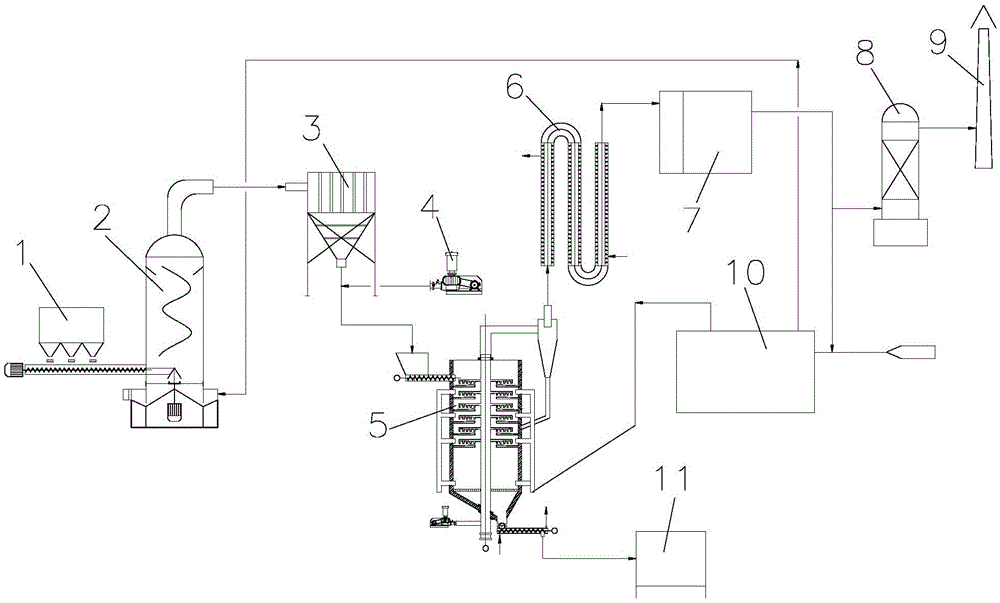

System for urban sludge flue gas drying middle-temperature pyrolysis carbonization

A technology for municipal sludge and flue gas waste heat, which is used in pyrolysis treatment of sludge, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Large resistance, low drying heat transfer efficiency, etc., to achieve the effect of reducing equipment investment, odorless operating environment, and saving energy consumption for transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

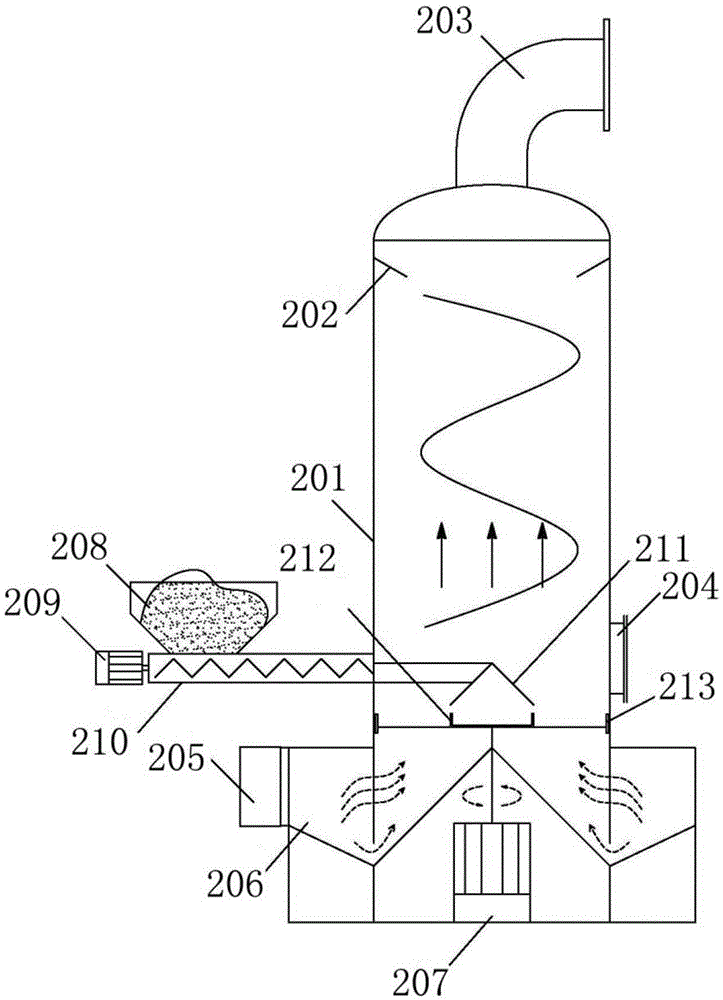

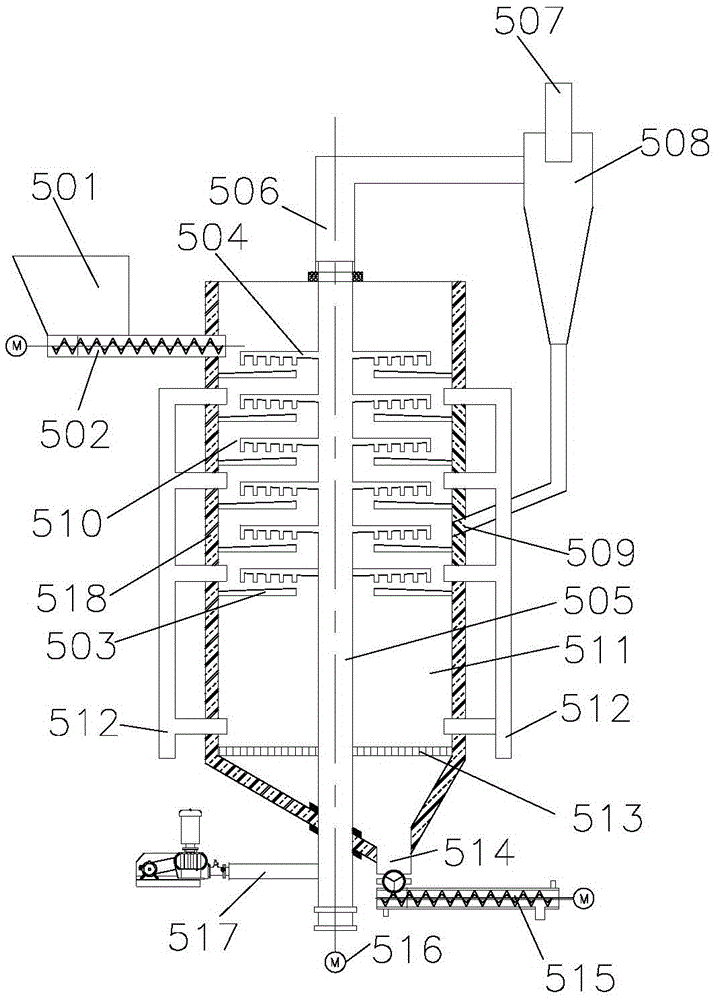

[0053] The dewatered sludge (water content 80%) of a sewage plant has a daily output of 20 tons, and the high solid content conveying pump is used to input the feed storage and metering system 1, and enter the low-temperature flue gas drying system 2 for drying to reduce the water content To 30-40%, the reduction is 5.71-6.67 tons. After drying, the sludge is sent to the medium-temperature pyrolysis carbonization system 5 through the pneumatic conveying equipment 4. The pyrolysis reaction temperature is 650-800°C. After the pyrolysis reaction, 2.42 tons of carbonized products and pyrolysis gas are produced, and the discharge temperature is 150-200°C. The charcoal at ℃ is cooled to below 30℃ by the water cooling unit and then sent to the subsequent resource utilization link. The pyrolysis gas at 600-750℃ is rapidly cooled and condensed to below 400℃ by the flue gas waste heat recovery system, and then sent to the flue gas drying system for dehydration The sludge is dried to a m...

Embodiment 2

[0062] The daily output of dewatered sludge (80% water content) in a sewage plant is 20 tons. After high dryness dehydration, the water content is reduced to 40%, and the reduction is 6.67 tons. The high solid content conveying pump is used to input the feed storage and metering system 1, and enter the low-temperature flue gas drying system 2 for drying, reducing the moisture content to 20-30%, and the weight reduction is 5.0-5.71 tons. After drying, the sludge is sent to the medium-temperature pyrolysis carbonization system 5 through the pneumatic conveying equipment 4. The pyrolysis reaction temperature is 650-800°C. After the pyrolysis reaction, 2.42 tons of carbonized products and pyrolysis gas are produced, and the discharge temperature is 150-200°C. The charcoal at ℃ is cooled to below 30℃ by the water cooling unit and then sent to the subsequent resource utilization link. The pyrolysis gas at 600-750℃ is rapidly cooled and condensed to below 400℃ by the flue gas waste he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com