Cell culture sedimentation device

A settling device and cell culture technology, applied in the field of machinery, can solve the problems of difficulty in magnification and blockage of rotating screen cells, and achieve the effects of convenient and reliable operation and easy magnification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

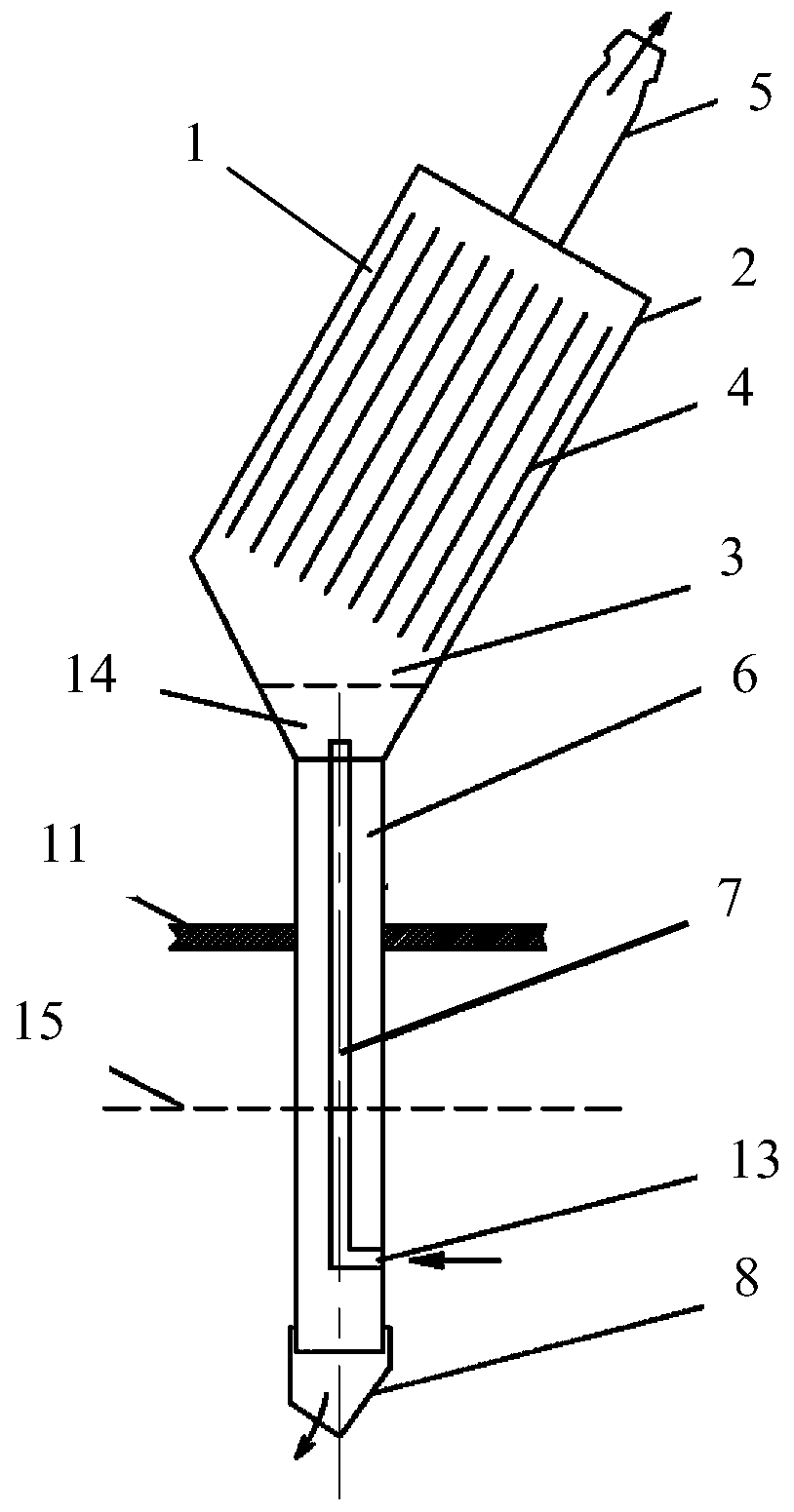

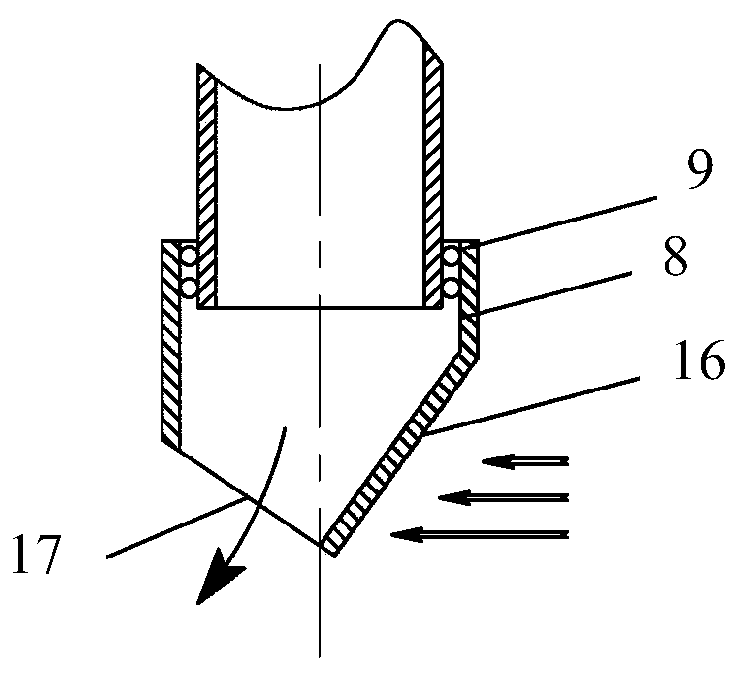

[0019] like figure 1 and figure 2 As shown, the cell culture settling device of the present invention includes a container 1, wherein the container 1 includes a settling chamber 2 and a transition chamber 3, the settling chamber 2 is provided with a settling unit 4, and the upper part of the container 1 is provided with a The liquid collection pipe 5, the liquid collection pipe 5 communicates with the upper part of the settling chamber 2, the transition chamber 3 is connected to the bottom of the settling chamber 2, the diameter of the transition chamber 3 decreases from top to bottom, and the lower end of the container 1 is connected with an outer pipe 6. The upper end of the outer tube 6 communicates with the transition cavity 3, and an inner tube 7 is arranged inside the outer tube 6. There is a gap between the outer wall of the inner tube 7 and the inner wall of the outer tube 6, and the upper end of the inner tube 7 extends to the transition cavity 3 and communicates w...

Embodiment 2

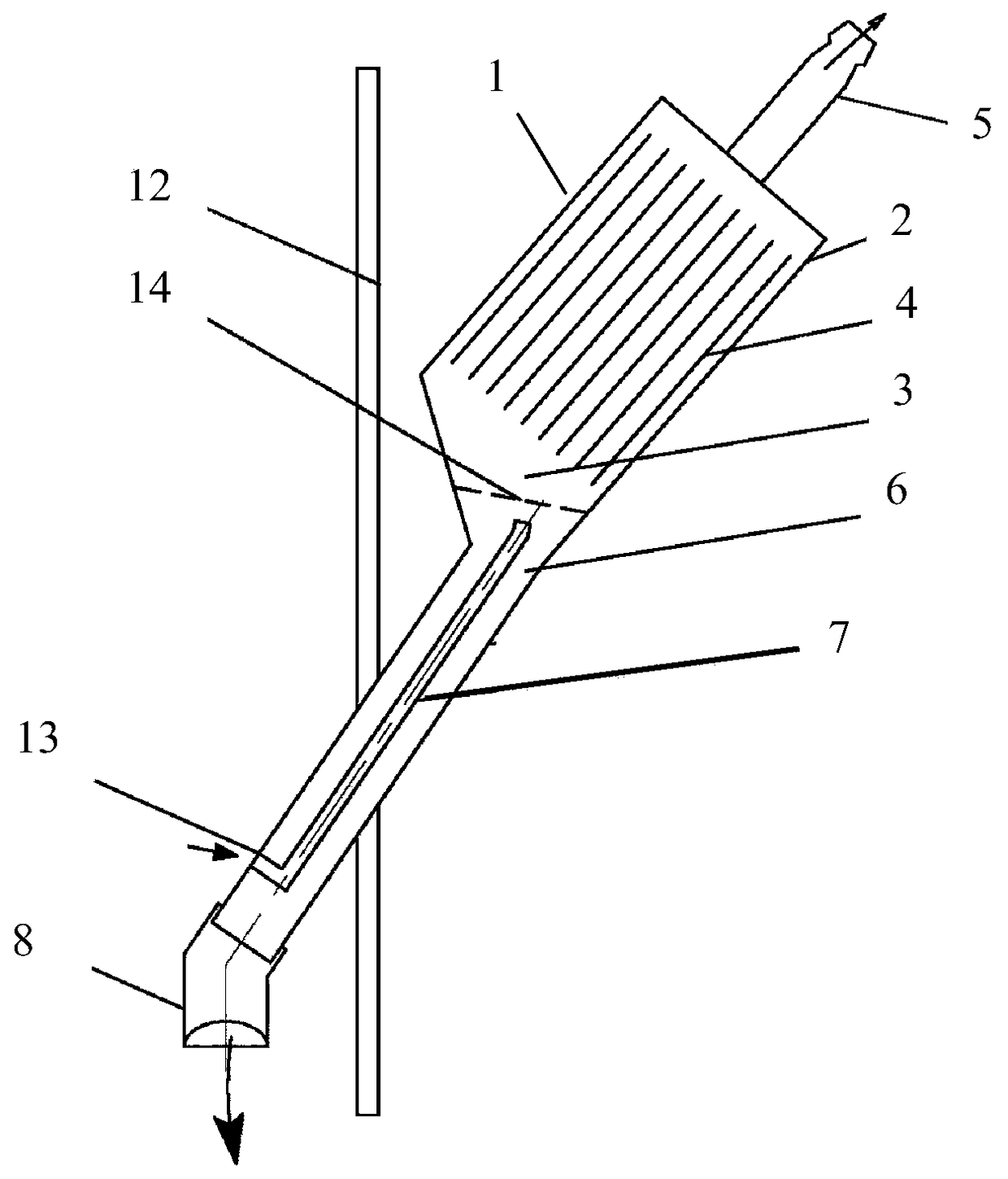

[0027] like image 3 and Figure 4 As shown, the outer tube 6 is fixedly arranged in the side wall of a tank body 12, the outer wall of the outer tube 6 is connected to the side wall of the tank body 12, and the axial direction of the outer tube 6 is 10-50 degrees to the axial direction of the tank body 12. The included angle is , the container 1 is located outside the tank body 12 and above the connection between the outer tube 6 and the tank body 12 .

[0028] Further, the end tube 8 has a bend of 100-170 degrees in the axial direction.

[0029] The specific working principle of Embodiment 2 is: the outer tube 6 is fixed on the side of the tank body 12 . The liquid collection pump lifts the culture solution 15 in the tank into the transition chamber 3 through the end tube 8, the outer tube 6 and the inner tube 7. Under the action of the slope at the outlet of the end tube 8, a negative pressure is generated at the outlet of the end tube 8. When the liquid level 14 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com