Acidic normal-temperature degreasing agent and preparation method thereof

A degreasing agent, normal temperature technology, applied in the field of acidic normal temperature degreasing agent and preparation, can solve the problems of affecting the surface quality and brightness of the steel plate, the decrease of the adhesion of the steel plate surface coating, and the inability to remove the slight oxide film, etc., to shorten the cleaning cycle, excellent Adhesion, the effect of high feasibility of preparation and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

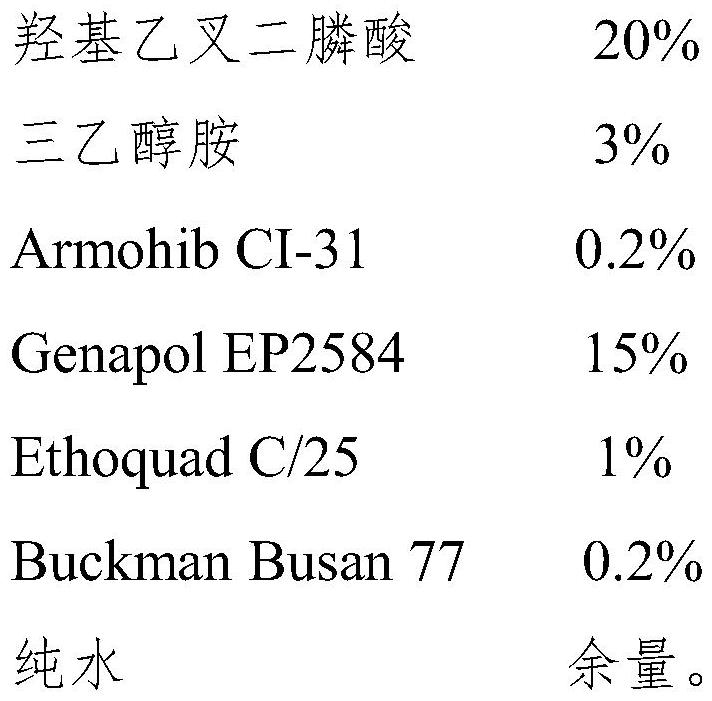

[0022] An acidic normal temperature skim, comprising the following mass percent component:

[0023]

[0024] Example 1 A method of preparation of an acidic normal temperature defective, including the following steps:

[0025] S1: In accordance with the above-mentioned mass percent, pure water is added to the stirred tank of the thermometer, the stirrer, and the drip apparatus, and the jacket of the stirred jacket is transferred into the cooling circulating water, stirred, and the hydroxy hem is bifid. Phosphonic acid and triethanolamine are sequentially added to pure water, stir evenly, and give a premix solution;

[0026] S2: When the premix solution is cooled to 10 ~ 35 ° C, the ARMOHIB CI-31, Ethoquad C / 25 and Buckman Busan 77 are first added to the primary premix solution prepared by step S1, stirred 10 ~ 30min, uniform solution, and obtain a secondary premixed solution;

[0027] S3: In accordance with the above-described mass percentage, GENAPOL EP2584 is added to the seco...

Embodiment 2

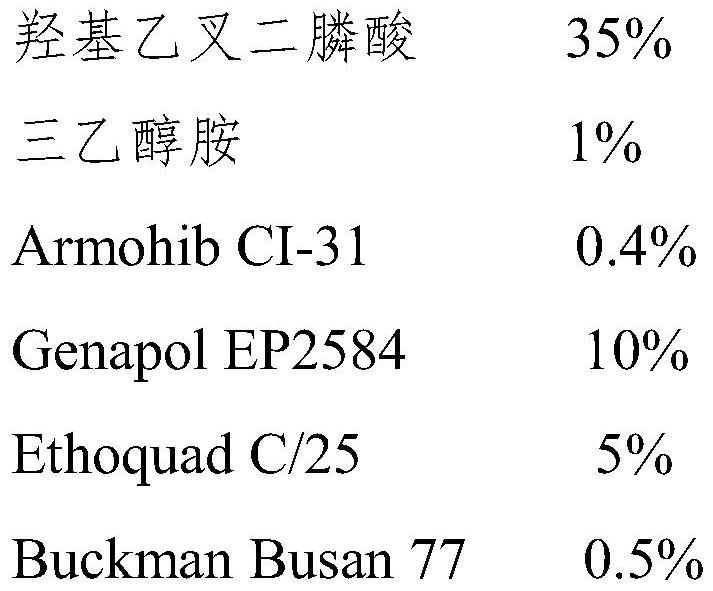

[0029] An acidic normal temperature skim, comprising the following mass percent component:

[0030]

[0031]

[0032] Example 2 The preparation method of an acidic normal temperature deactivated release agent is the same as the method of preparing an acid normal temperature defective agent in Example 1.

Embodiment 3

[0034] An acidic normal temperature skim, comprising the following mass percent component:

[0035]

[0036] Example 3 The preparation method of an acidic normal temperature degummia was the same as the preparation method of an acidic normal temperature defective in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com