Waste animal and vegetable grease fiber membrane water-washing desalination method and process system thereof

A technology of animal and vegetable oils and process systems, which is applied in the field of waste animal and vegetable oils and fats fiber membrane water washing desalination method and its process system, which can solve problems such as coking and corrosion, achieve the effect of reducing consumption, reducing consumption, and ensuring desalination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

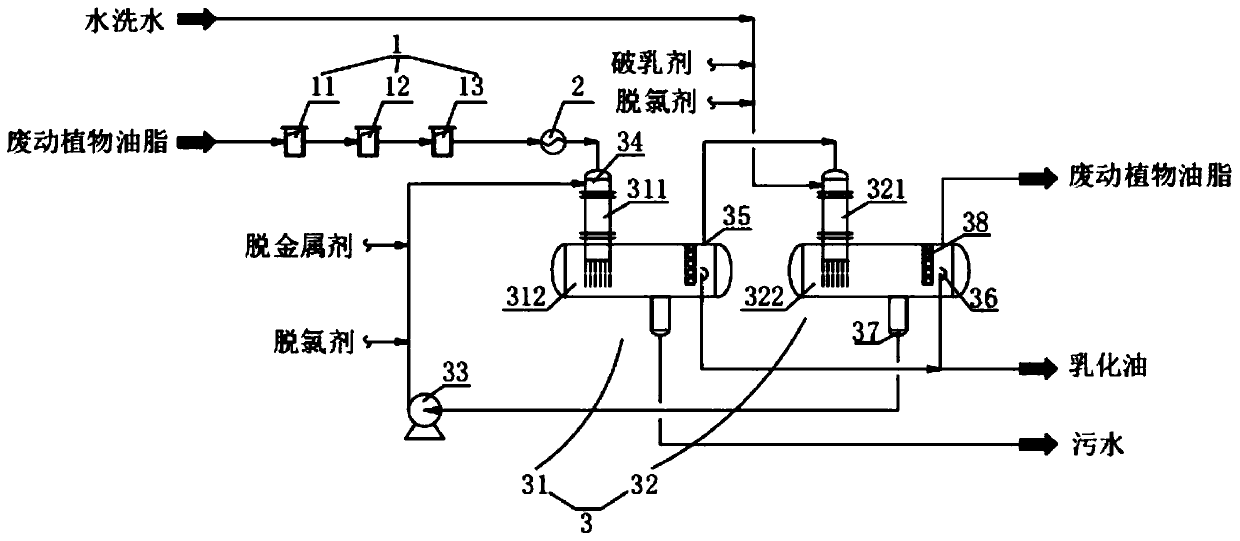

[0070] The raw materials of waste animal and vegetable oils from the tank area are filtered through three stages. The pre-filter adopts a filter with a filtration precision of 20 mesh; the filter of activated carbon or blue carbon adopts a filter with a filtration precision of 30 mesh; The precision reaches 25μm particles and the removal rate is over 98%. The operating temperature is 70°C and the operating pressure is 1.1MPa.

[0071] The fiber membrane is a hydrophilic fiber membrane, the washing water is deoxygenated water, and the volume ratio of the washing water entering the fiber membrane contactor to the waste animal and vegetable oil raw materials entering the fiber membrane contactor is 0.3. The operating temperature of waste animal and vegetable oil entering the first-stage fiber membrane contactor 311 is 120°C, and the operating pressure is 0.7MPa; the operating temperature of washing water entering the first-stage washing fiber membrane contactor 311 is 120°C, and ...

Embodiment 2

[0079] The raw materials of waste animal and vegetable oils from the tank area are filtered through three stages. The pre-filter adopts a filter with a filtration precision of 20 mesh; the filter of activated carbon or blue carbon adopts a filter with a filtration precision of 30 mesh; The precision reaches 25μm particles and the removal rate is over 98%. The operating temperature is 70°C and the operating pressure is 1.0MPa.

[0080] The fiber membrane is a hydrophilic fiber membrane, the washing water is deoxygenated water, and the volume ratio of the amount of washing water entering the fiber membrane contactor to the waste animal and vegetable oil raw materials entering the fiber membrane contactor is 0.1. The operating temperature of waste animal and vegetable oil entering the first-stage fiber membrane contactor 311 is 120°C, and the operating pressure is 0.7MPa; the operating temperature of washing water entering the first-stage washing fiber membrane contactor 311 is 1...

Embodiment 3

[0088] The raw materials of waste animal and vegetable oils from the tank area are filtered through three stages. The pre-filter adopts a filter with a filtration precision of 20 mesh; the filter of activated carbon or blue carbon adopts a filter with a filtration precision of 30 mesh; The precision reaches 25μm particles and the removal rate is over 98%. The operating temperature is 70°C and the operating pressure is 1.0MPa.

[0089]The fiber membrane is a hydrophilic fiber membrane, the washing water is deoxygenated water, and the volume ratio of the washing water entering the fiber membrane contactor to the waste animal and vegetable oil raw materials entering the fiber membrane contactor is 0.2. The operating temperature of waste animal and vegetable oil entering the first-stage fiber membrane contactor 311 is 120°C, and the operating pressure is 0.7MPa; the operating temperature of washing water entering the first-stage washing fiber membrane contactor 311 is 120°C, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com