Floating-type device for rock embedment mounting of steel pipe pile in water and construction method thereof

A floating device, steel pipe pile technology, applied in the direction of support device, sheet pile wall, earthwork drilling, etc., can solve the problems of poor construction stability, inability to carry out work, limited space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the present invention will be further described.

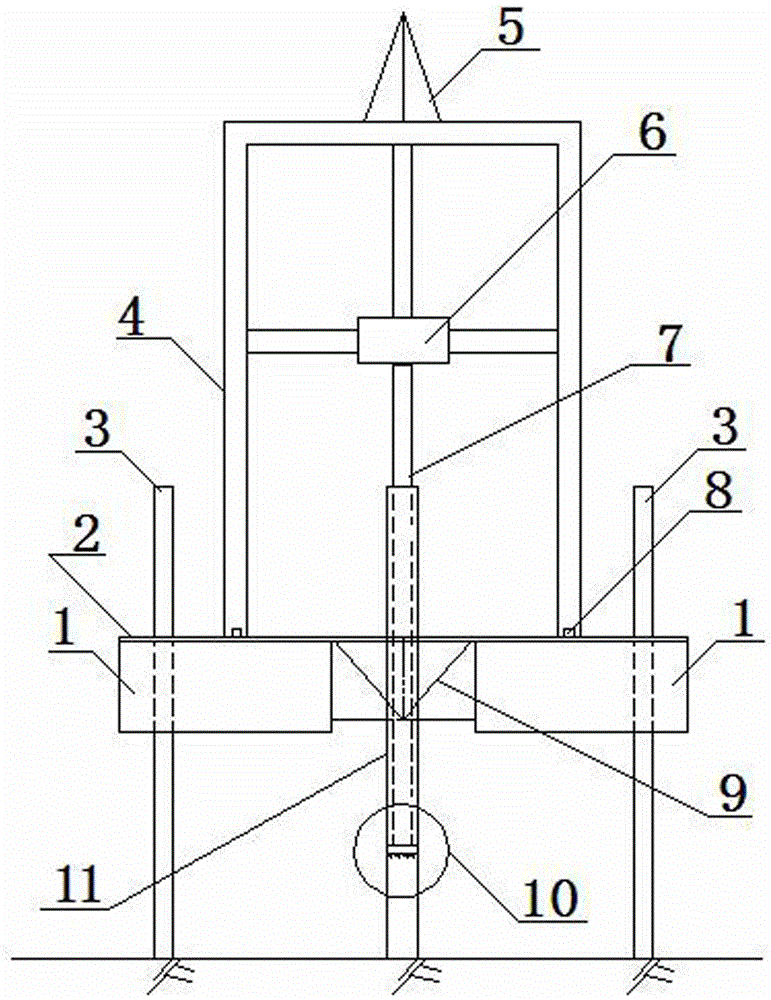

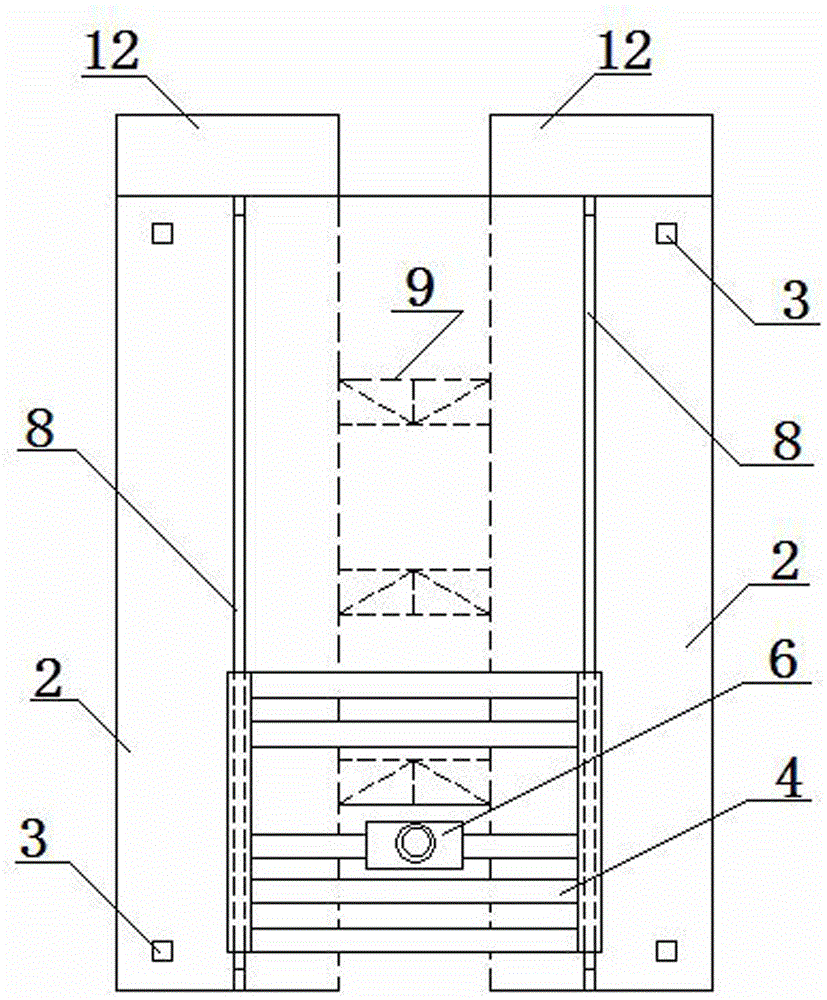

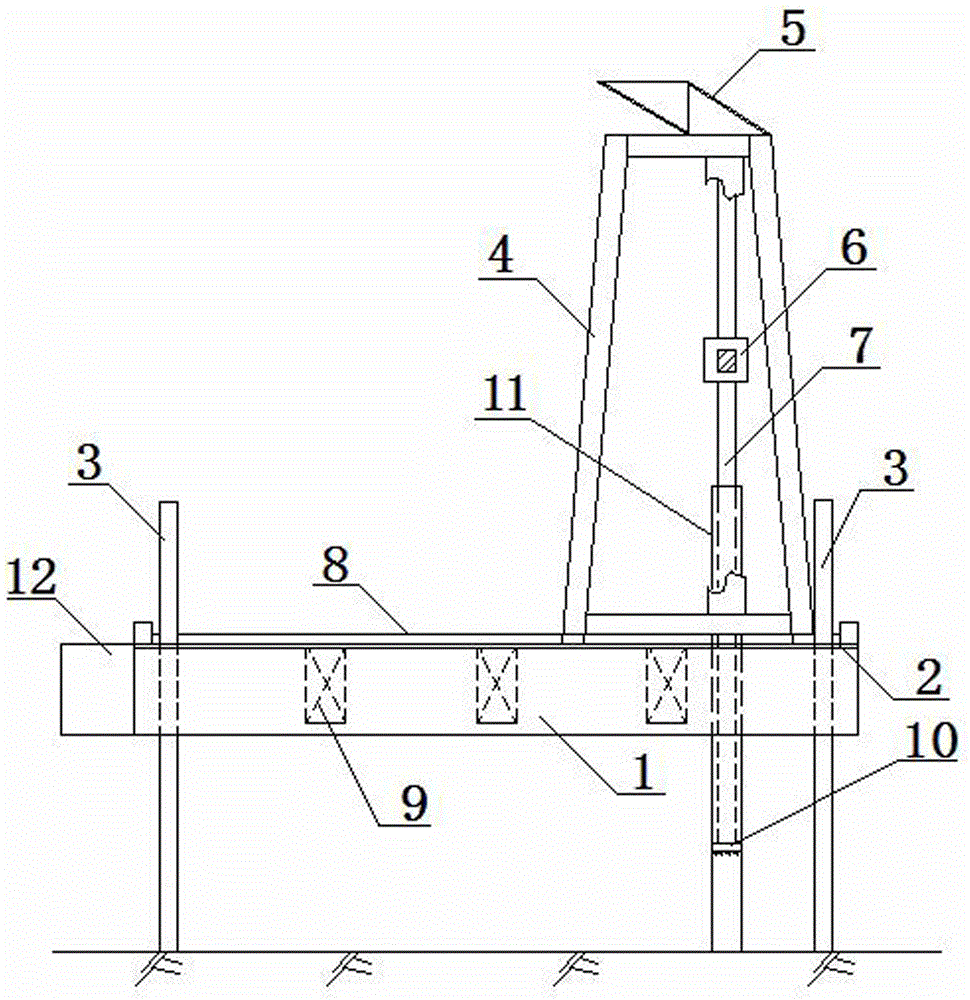

[0033] figure 1 Shown is a schematic view of the structure of the present invention, figure 2 shown, is figure 1 The schematic diagram of the top view structure, image 3 shown, is figure 1 The structure schematic diagram of the left view, as can be seen from the figure, the present invention comprises: pontoon 1, platform 2, hydraulic support column 3 and door frame 4. Among them, on both longitudinal sides below the platform 2, buoyancy tanks 1 are fixedly connected at intervals, and between the buoyancy tanks 1, several groups of trusses 9 are fixed at transverse intervals. The two ends of each truss 9 are respectively fixedly connected with the pontoon 1 on both sides; the platform 2 and the pontoon 1 are connected as a whole through the truss 9. The specific method is: the truss 9 is welded between the pontoon 1 at intervals, first The two buoyant tanks 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com