Construction method of rear welded joints of a truss

A construction method and truss technology, applied in the direction of building, building structure, etc., can solve the problems of large columns and bad lateral pressure, and achieve the effect of improving the bearing capacity, improving the use efficiency and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

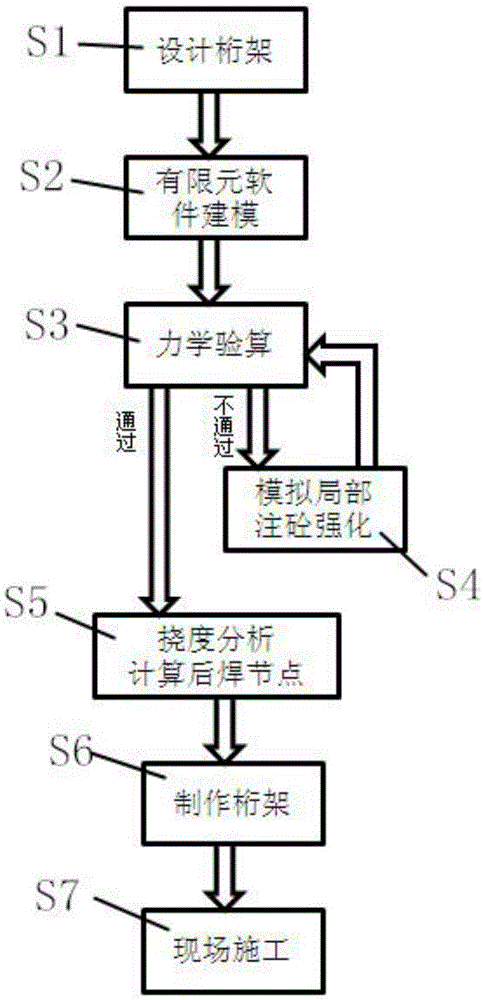

[0050] The construction method of welded joint after the truss of the present invention, as figure 1 , Figure 7 to Figure 9 shown, including the following steps:

[0051] S1: Collect building construction requirements, design truss 1 structure, such as Figure 9 As shown, the truss 1 is a two-way truss, including an upper chord 11, a lower chord 12, and a web 13 connected between the upper chord 11 and the lower chord 12, and the preferred truss 1 is a steel box truss;

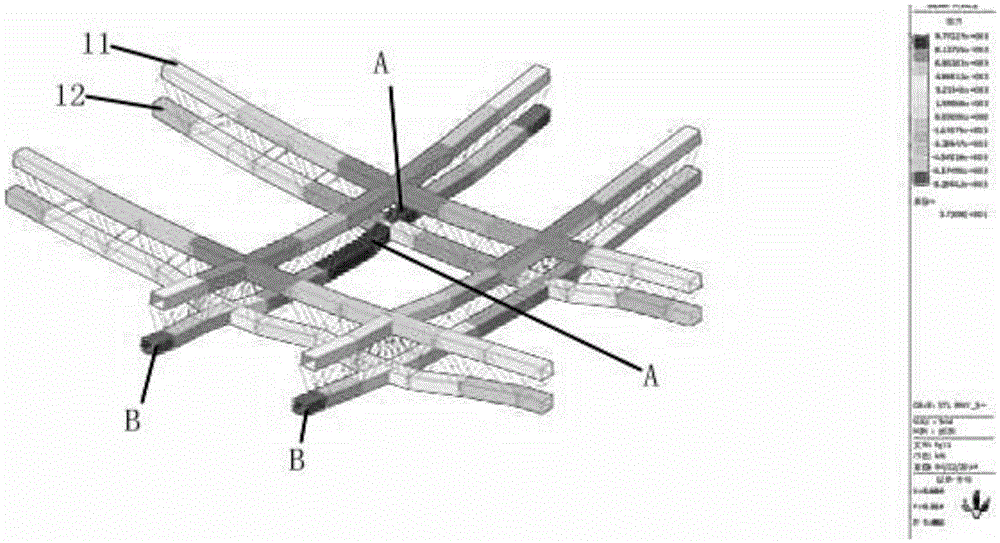

[0052] S2: Use finite element software to establish truss 1 and the structural model of the substructure and superstructure connected by truss 1, such as Figure 8 As shown, the truss 1 is connected to the superstructure and the substructure through a plurality of columns 4;

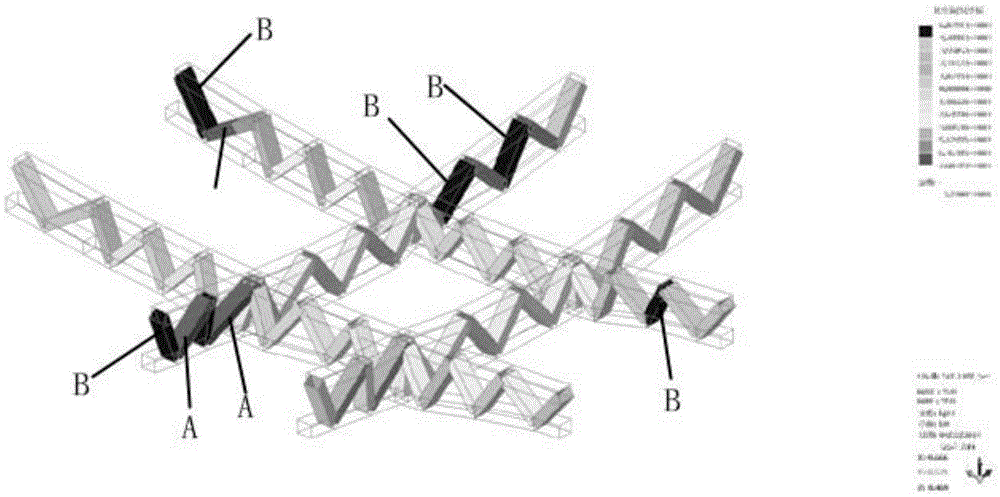

[0053] S3: Use finite element software to perform mechanical check on the model, and calculate the pressure value of the compressed chord or web 13 of the truss 1. If the pressure value of the chord or web 13 exceeds the preset value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com