Carbon-fiber-based reinforcing ring of pipe penetrating through active fault area

An active fault, carbon fiber technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of large bending deformation of pipes, excessive stress and strain of pipes, etc., to avoid stress concentration, simple manufacturing process and construction. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

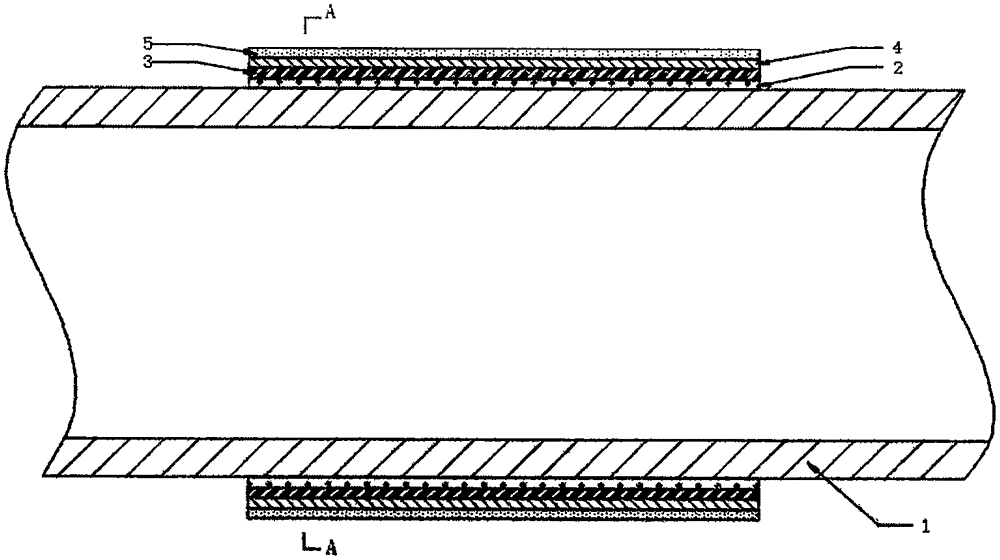

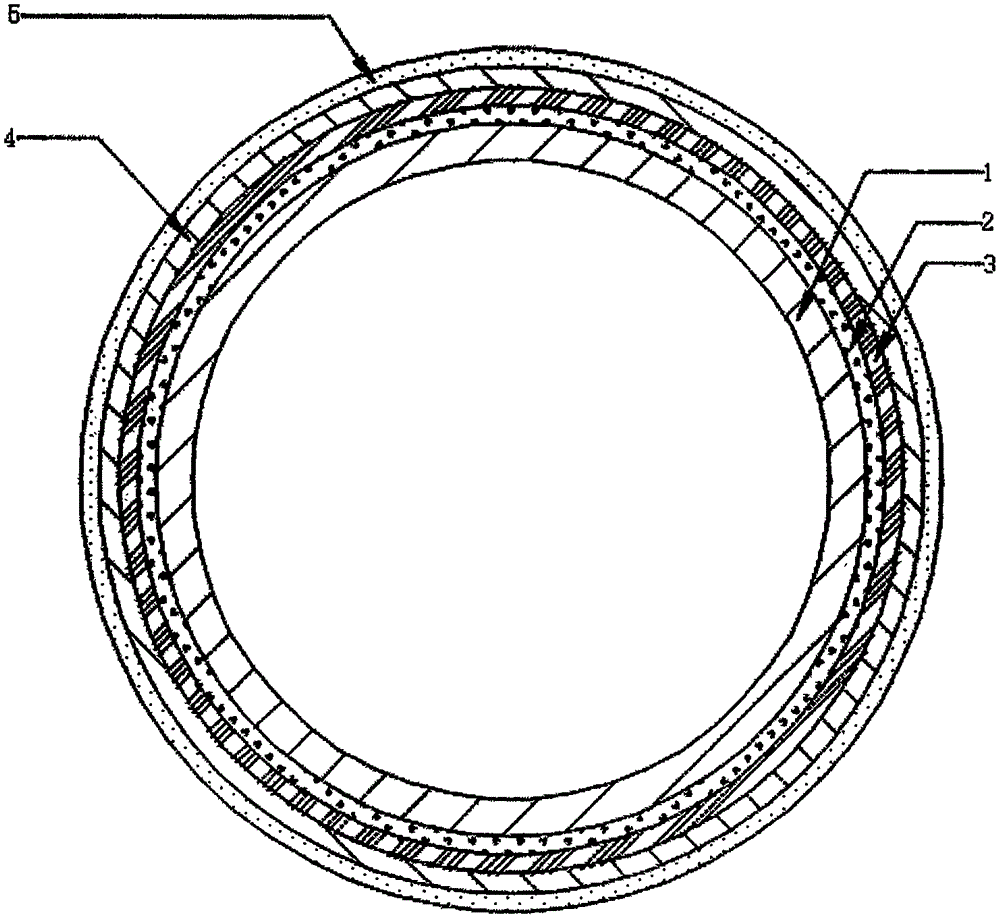

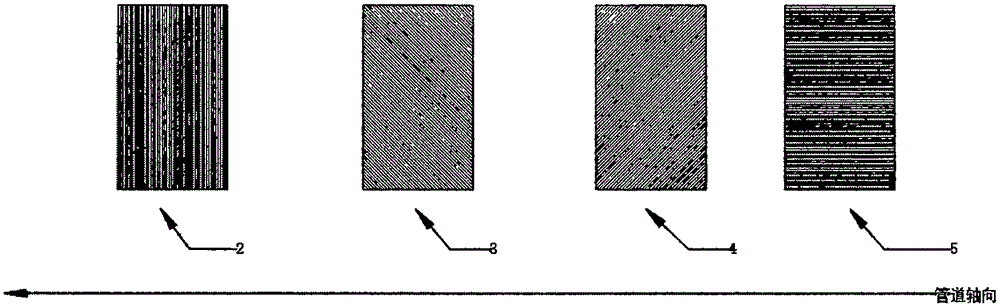

[0020] like figure 1 , figure 2 , image 3 As shown: 1 is the pipe wall of the pipeline passing through the active fault zone, the surface of 1 is the anti-corrosion layer of the pipeline, 2 is the carbon fiber cloth layer with a 90-degree angle between the texture in the reinforcement circle and the pipeline axis, and 3 is the texture in the reinforcement circle and the pipeline axis 4 is a carbon fiber cloth layer with a negative 45-degree angle between the texture in the reinforcement ring and the axial direction of the pipe, and 5 is a carbon fiber cloth layer with a 0-degree angle between the texture in the reinforcement ring and the axial direction of the pipe.

[0021] The fabrication and installation method of the present invention comprises the following steps:

[0022] (1) Pipe surface treatment

[0023] Sandblasting is used to treat th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com