Flexible pipe standard mark structure

A technology of flexible pipes and leveling standards, applied in height/level measurement, measuring devices, instruments, etc., can solve the problems of unsatisfactory accuracy, unsatisfactory use effect, large drilling diameter, etc., and achieve simple construction, strong applicability, The effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

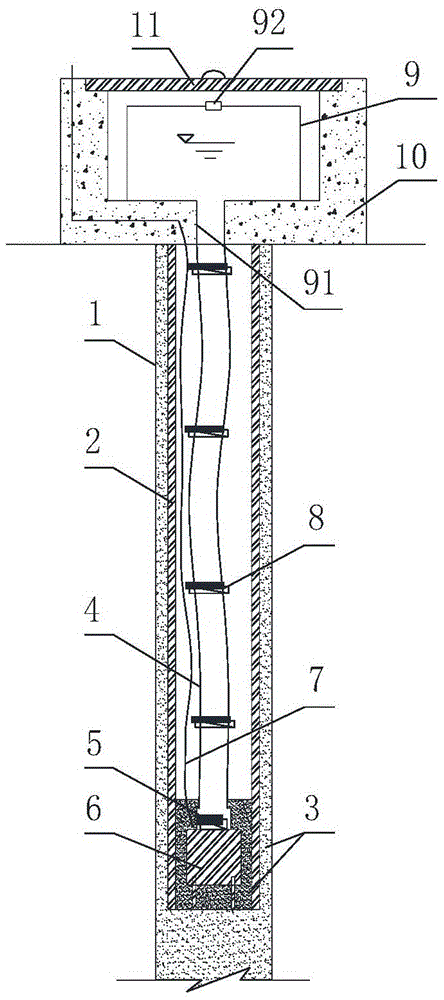

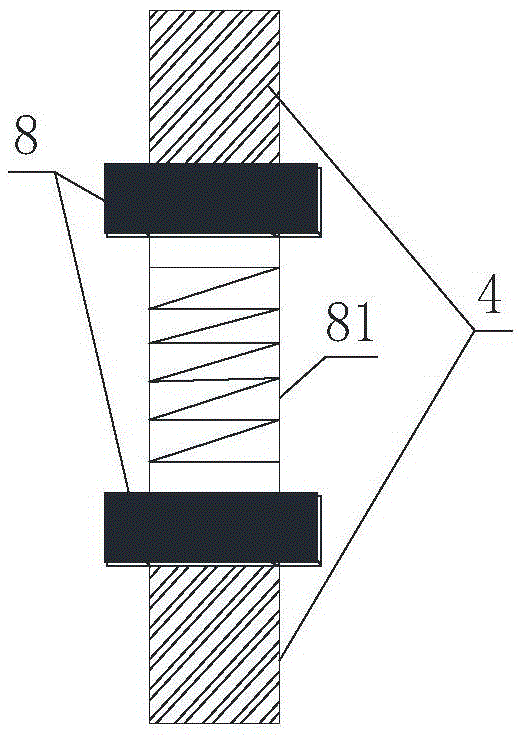

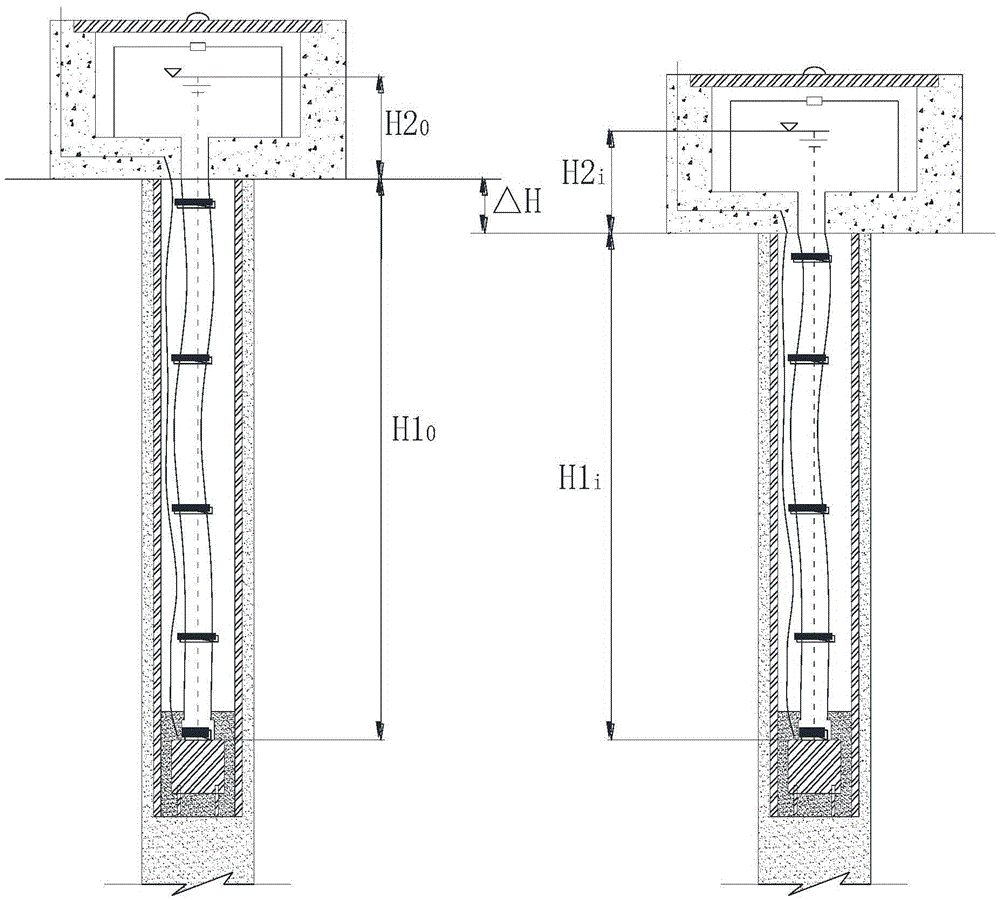

[0027] Such as figure 1 , figure 2 As shown, a flexible pipe leveling structure according to the present invention includes a borehole 1 and a steel protection pipe 2 installed in the borehole 1, the bottom of the borehole 1 goes deep into the bedrock, and the steel protection pipe 2 is fixed in the borehole 1 by cement mortar 3, and the hole wall of the borehole 1 is protected to avoid large lateral displacement of the borehole. The steel protection pipe 2 is also equipped with a flexible pipe 4, and the flexible pipe 4 The pipe 4 is installed in sections, and each section of the flexible pipe 4 is connected by a sealing joint 8, and the inside of the sealing joint 8 is provided with a freely retractable bellows 81, and the bottom of the flexible pipe 4 is consolidated There is a ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com