Tyre six-component force testing device for eliminating unbalance loading

A test device and six-component force technology, which is applied in the direction of automobile tire testing, etc., can solve the problems of high-precision and large-range six-component force sensor, which are expensive, the measuring range cannot meet the requirements, and the tire load is large, so as to meet the mechanical characteristics test, The effect of simple and reasonable structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

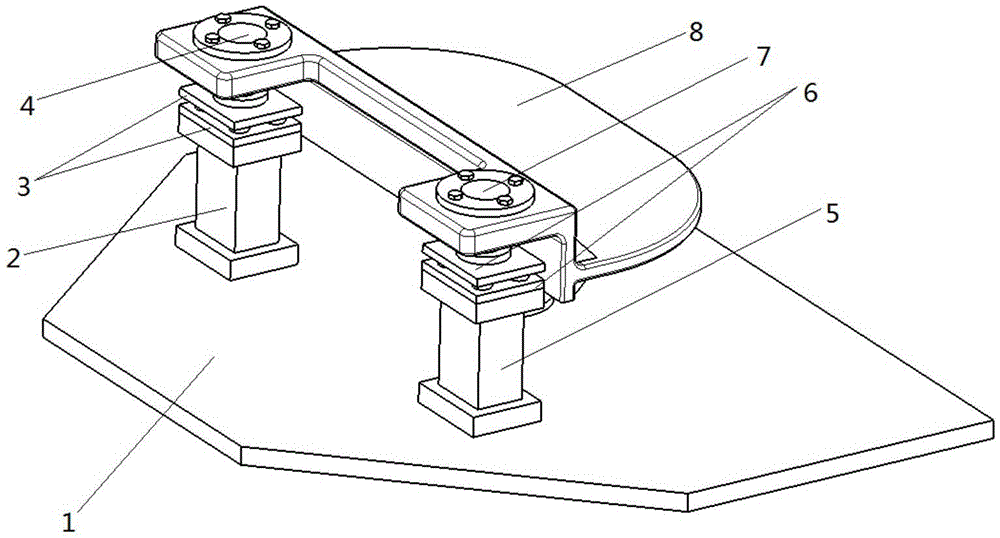

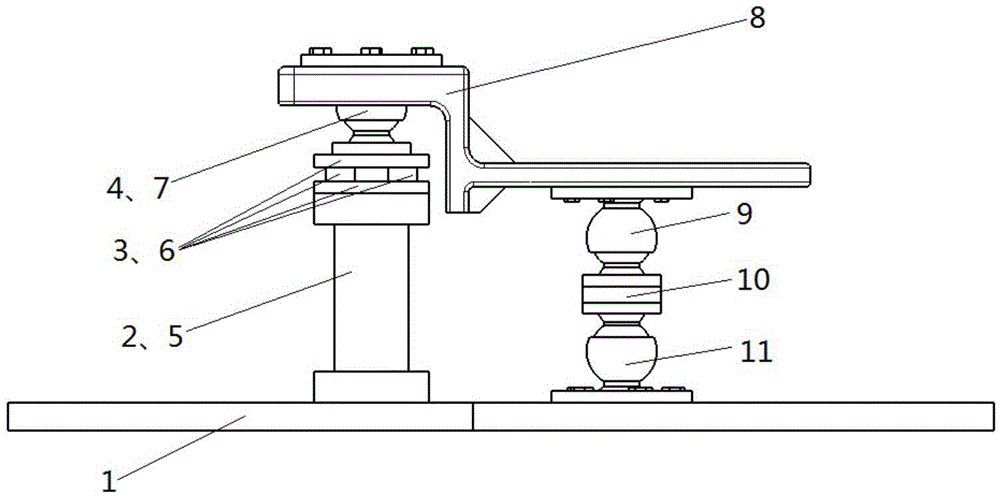

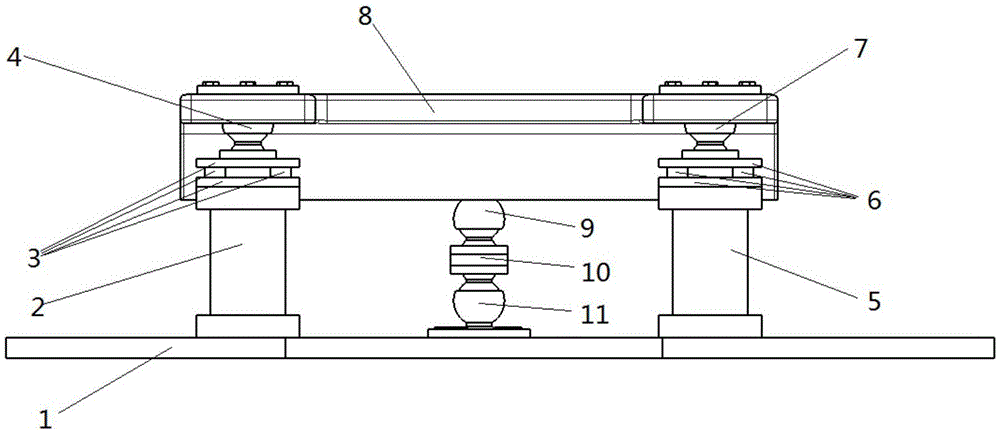

[0026] attached by figure 1 , 2 , shown in 3: the device includes base 1, pillar one 2, six-component force sensor one 3, ball joint one 4, pillar two 5, six-component force sensor two 6, ball joint two 7, bearing plate 8, ball joint three 9. Single component force sensor 10, ball joint four 11.

[0027] The upper end of the ball joint-4 is fixed on the bearing plate 8, the lower end of the ball joint-4 is fixed with the upper end of the six-component force sensor-3, the lower end of the six-component force sensor-3 is fixed on the pillar-2, and the pillar-2 is fixed on the On the base 1; the upper end of the ball joint 2 7 is fixed on the bearing plate 8, the lower end of the ball joint 2 7 is fixed to the upper end of the six-component force sensor 2 6, and the lower end of the six-component force sensor 2 6 is fixed on the pillar 2 5, the pillar Two 5 are fixed on the base 1.

[0028] The spherical hinge one 4 and the spherical hinge two 7 are symmetrically distributed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com