A free-form surface lens with high light extraction efficiency and its design method

A technology of curved lens and design method, which is applied in the fields of lens, optics, computing, etc. It can solve the problems of not considering the light output efficiency of the lens, and achieve the effect of simple design method, small loss of light energy and great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

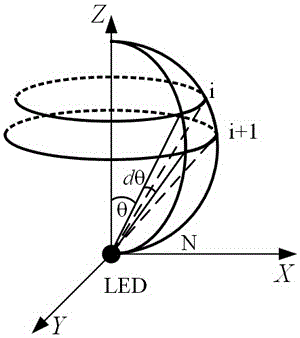

[0053] S1. In this embodiment, the XOZ plane is selected as the incident surface, the light source is located at the coordinate origin O, and the light distribution curve of the light source, that is, the spatial intensity distribution of the light energy of the light source is Lambertian. Divide the light energy emitted from the light source into N=200 parts, then each equally divided angle θ i Can be determined by the formula:

[0054]

[0055] Find

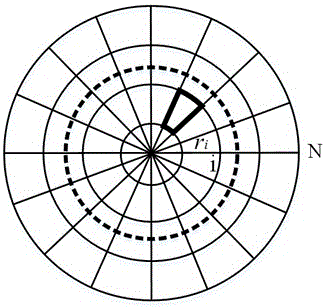

[0056] S2. In this embodiment, the shape of the illumination area is selected as a circle, the radius is R=100mm, the distance between the illumination area and the center of the LED is L=50mm, and the illuminance distribution is that all areas in the spot have equal illuminance. Then, the target surface 100 is also divided into N=200 parts according to the spot shape and illumination distribution requirements. Then the spot radius corresponding to each area can be calculated by the formula:

[0057]

[0058] Find

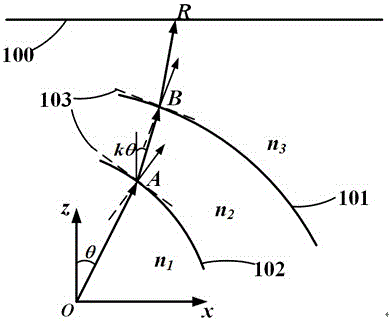

[0059] S3. In thi...

Embodiment 2

[0066] Repeat embodiment 1 with the same steps as described, the difference is that the free-form surface material in this embodiment is PC (polycarbonate), the height of the center point of the inner surface 102 is 5mm, and the height of the center point of the outer surface 101 is 8mm; The angular deflection coefficient of the inner surface 102 is k=1. The target surface is a circle with a radius of R=200mm, and the distance from the light source to the target surface 100 is L=100mm. Picture 9 The topography of the free-form surface lens of this embodiment, Picture 10 This is the illuminance distribution diagram of the free-form surface lens on the target surface 100 in this embodiment. After calculation, the uniformity of illumination is 0.94, the Fresnel optical loss is 9.8%, and the light extraction efficiency is 90.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com