Distributed control system and control method for conveyer

A distributed control and conveyor technology, applied in the general control system, control/adjustment system, test/monitoring control system, etc., can solve the problems of difficult acquisition and processing of underlying data, inconvenient maintenance and repair, and high failure rate. Achieve rich and flexible conveying functions, save manpower, and facilitate maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

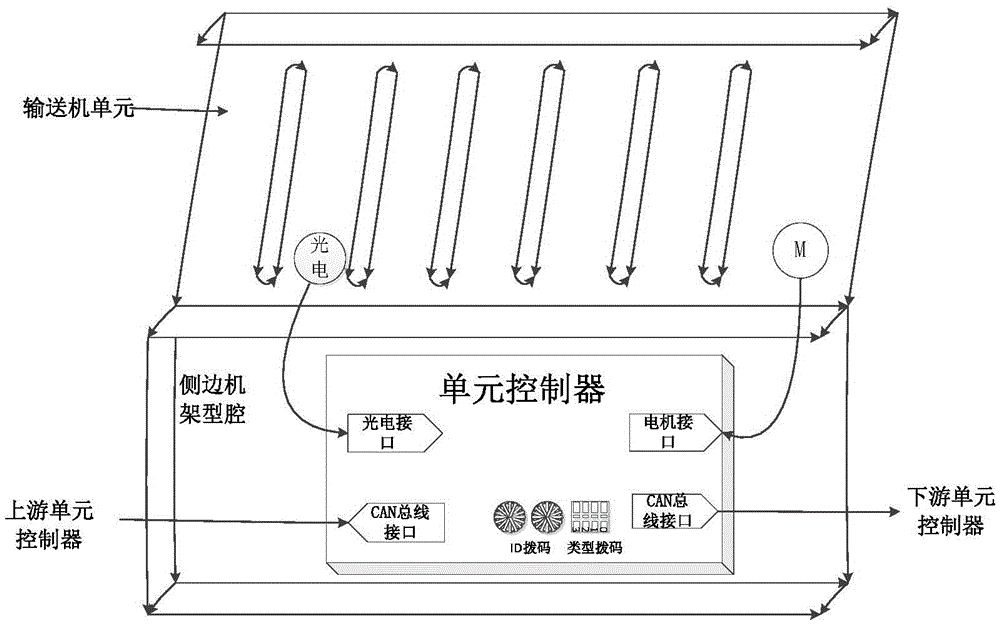

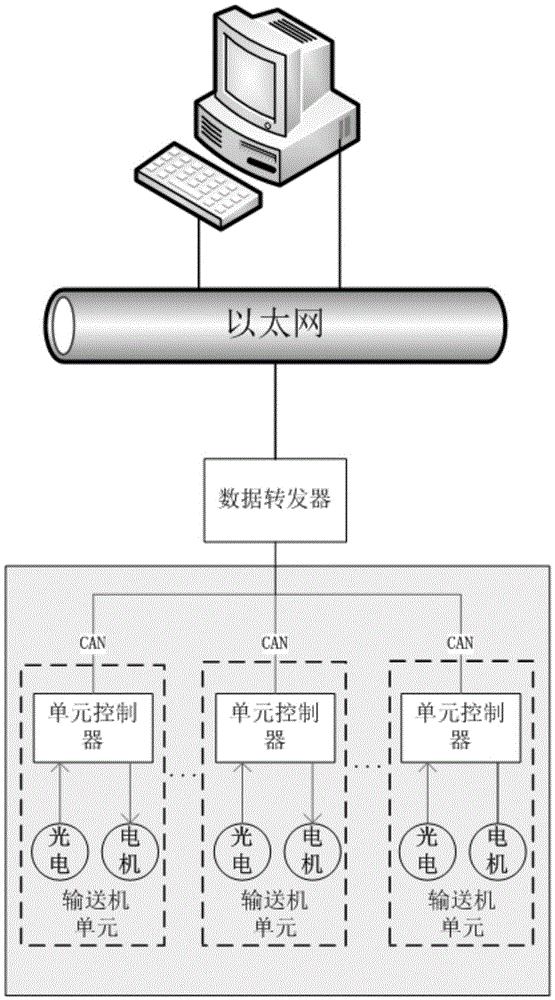

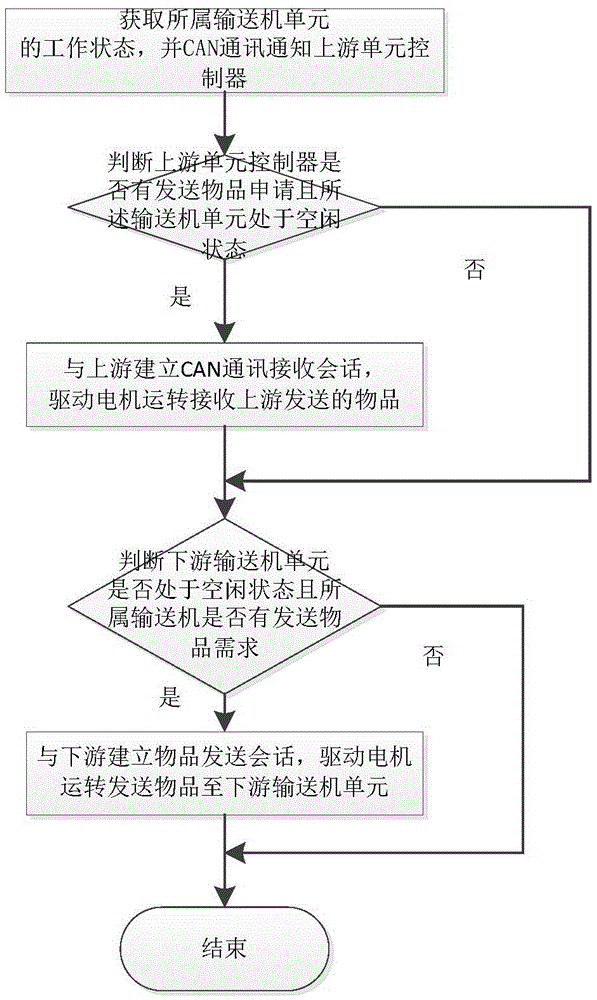

[0034] refer to figure 1 , figure 2 As shown, a conveyor distributed control system of the present invention is applied to a conveyor composed of a plurality of conveyor units connected, including: a data interface terminal, a data transponder, and a unit controller; wherein,

[0035] The data interface terminal monitors the status of the conveyor, conveys business logic control, and provides system maintenance and diagnosis; in the embodiment, the data interface terminal is a computer connected to the cloud database through the Ethernet network. Conveyor: Operators can check the working status and fault conditions of each conveyor unit in the conveyor through the computer, which is conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com