Infrared monitoring early warning system for belt conveyer key part

A belt conveyor and belt conveying technology, applied to computer parts, character and pattern recognition, instruments, etc., can solve problems such as inaccurate positioning, inability to predict in advance, and intermittent detection points, so as to improve the production environment and enhance Monitor the level of early warning and the effect of production safety, good interactivity and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

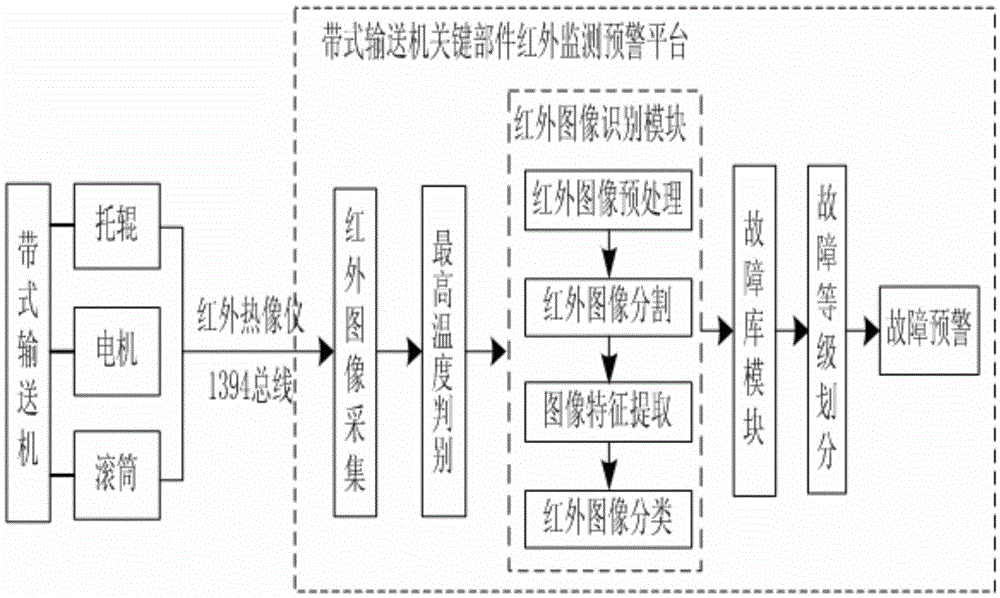

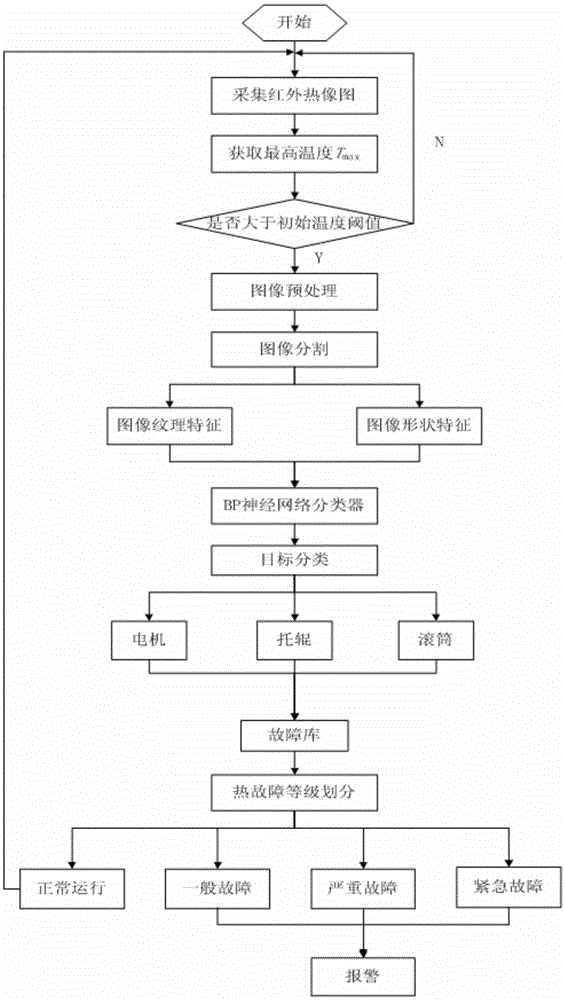

[0029] Such as figure 1 As shown, the system includes a belt conveyor, an infrared thermal imager, and an infrared monitoring and early warning platform for key components of the belt conveyor.

[0030] The key components of the belt conveyor include rollers, rollers and motors;

[0031] The infrared thermal imager is used to collect infrared images of key components of the belt conveyor;

[0032] The infrared monitoring and early warning platform for key components of the belt conveyor includes an infrared image acquisition module for key components of the belt conveyor, a maximum temperature discrimination module, an infrared image recognition module for key components, a fault library module, a fault level division module, and a fault early warning module;

[0033] The infrared image acquisition module transmits the infrared image of the key components of the belt conveyor collected by the infrared thermal imager to the infrared monitoring and early warning platform for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com