A core melt trap

A technology of core melt and melt, applied in the direction of reactors, reduction of greenhouse gases, climate sustainability, etc., can solve the problems of accumulation of core melt, unfavorable cooling of core melt, and failure to consider the use of blasting devices, etc. , to achieve the effect of high availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

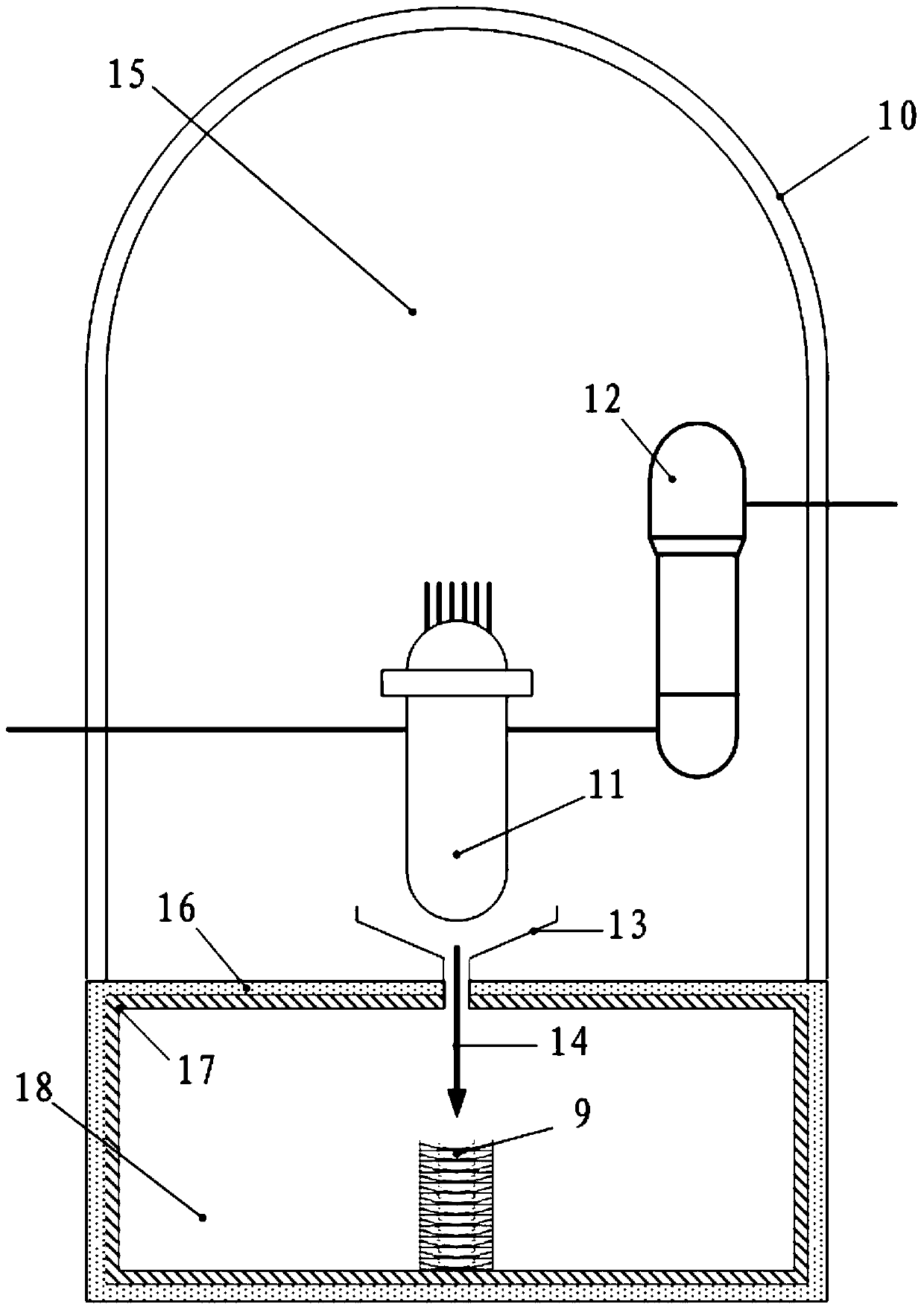

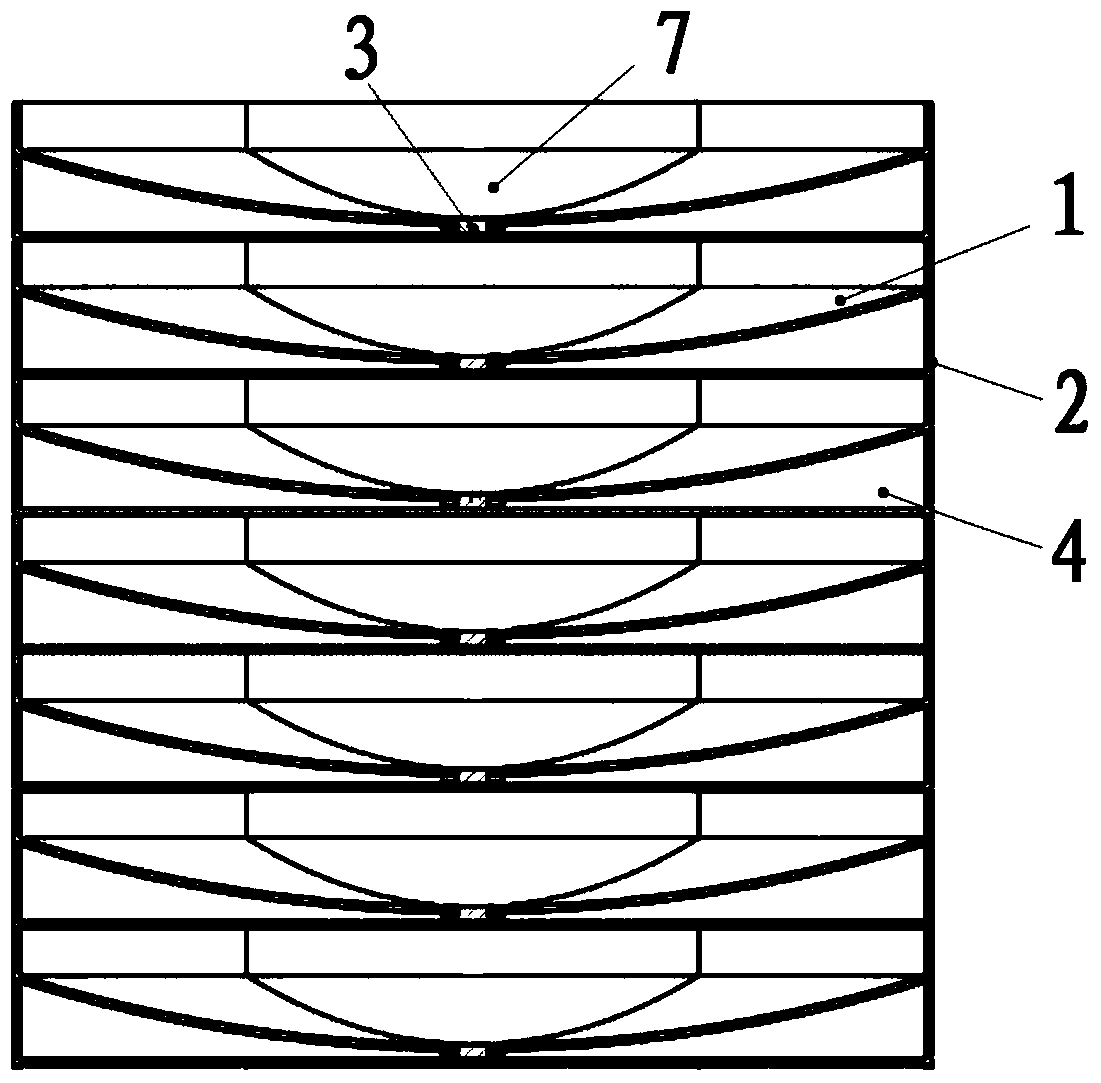

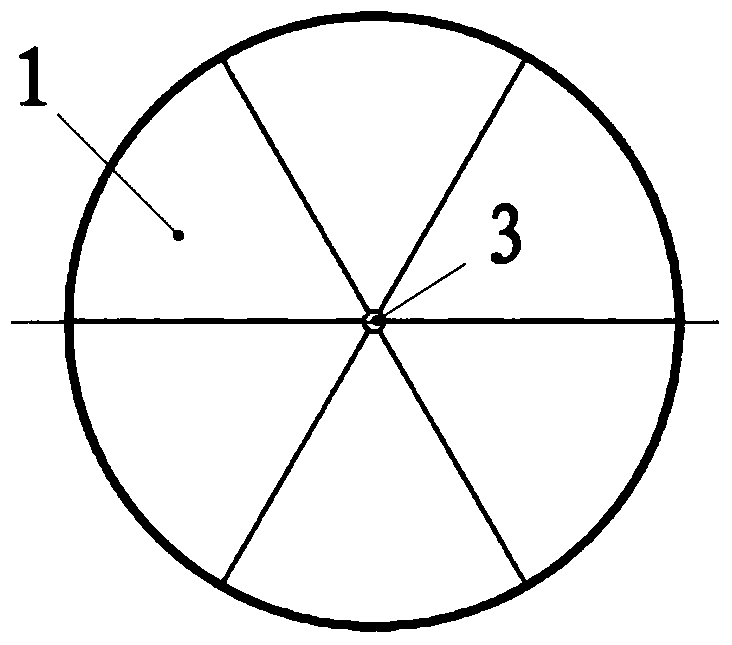

Embodiment 1

[0036] The molds of the smelt retention trays of the blasting units provided by the first embodiment and the second embodiment are different, and the blasting and spreading directions of the core melts are different (the spreading direction of the first embodiment is the oblique upward direction of the blasting unit, and the spreading direction of the second embodiment is is the horizontal side and oblique downward direction of the blasting unit), which can be adopted as appropriate according to the volume of the core trap and other specific factors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com