Vibration and noise reduction device of transformer

A vibration and noise reduction, transformer technology, applied in transformer/inductor noise damping, transformer/reactor installation/support/suspension, spring/shock absorber design features, etc., can solve severe environmental vibration and noise, increase transformer Cost, induced structural noise and other issues, to achieve good energy absorption and buffering effect, prevent structural instability, and reduce mechanical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

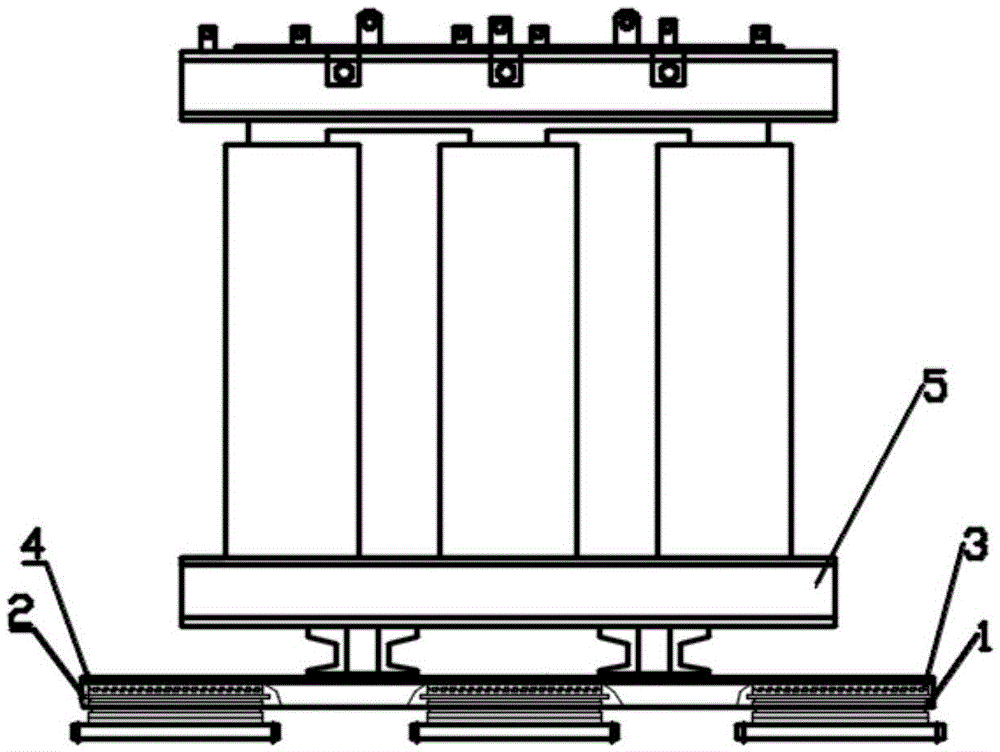

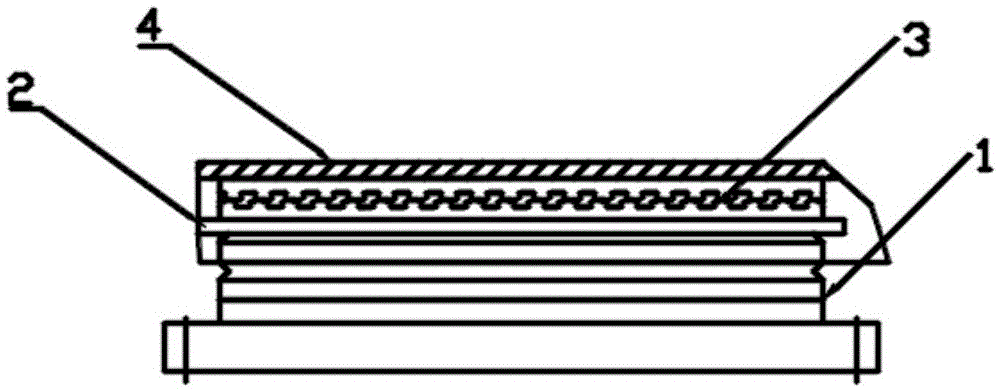

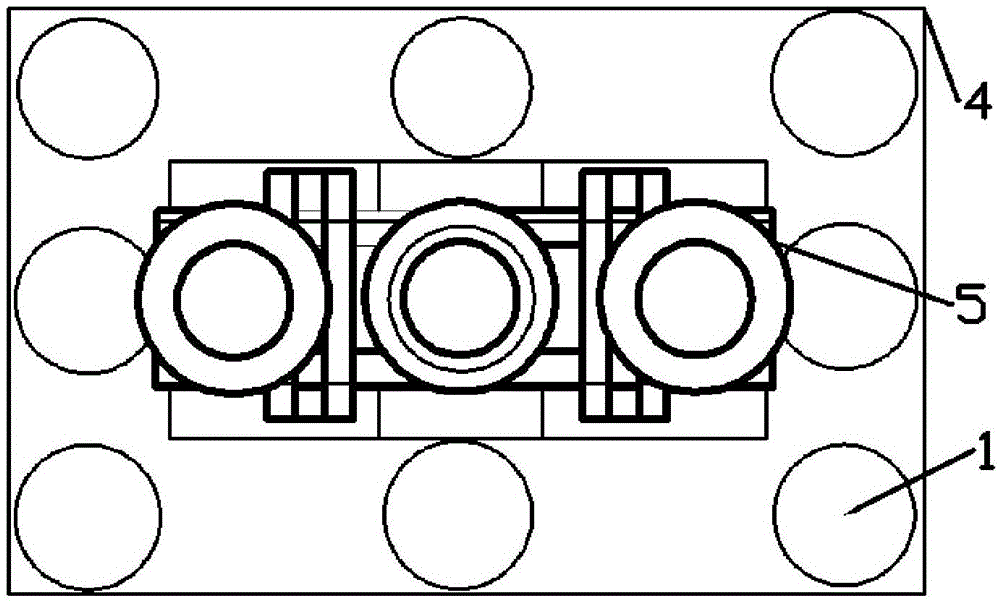

[0026] Such as figure 1 As shown, this embodiment provides a transformer vibration and noise reduction device, including a polyurethane buffer 1, an intermediate partition 2, a shock-absorbing rubber pad 3 and a C-shaped channel steel frame 4 connected sequentially from bottom to top, and the polyurethane buffer 1 Form a fixed connection with the ground, one side of the opening of the C-shaped channel steel frame 4 faces the shock-absorbing rubber pad 3, and the shock-absorbing rubber pad 3 is nested in the C-shaped steel channel frame 4, and the other side of the C-shaped steel channel frame 4 is fixedly installed Transformer base 5.

[0027] The polyurethane buffer 1 has a microporous air bubble structure, which is connected to the ground through bolts. Thereby greatly reducing the transmission of the vibration of the transformer to the ground, so as to achieve the purpose of reducing the vibration of the transformer and noise pollution.

[0028] The shock-absorbing rubber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com