Automatic auxiliary apparatus for solar module power tester alignment

A technology of solar modules and auxiliary devices, which is applied in the monitoring of electrical components, semiconductor devices, photovoltaic systems, etc. It can solve problems such as the impact of component accuracy, achieve the effects of improving productivity, making calibration work easy and convenient, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

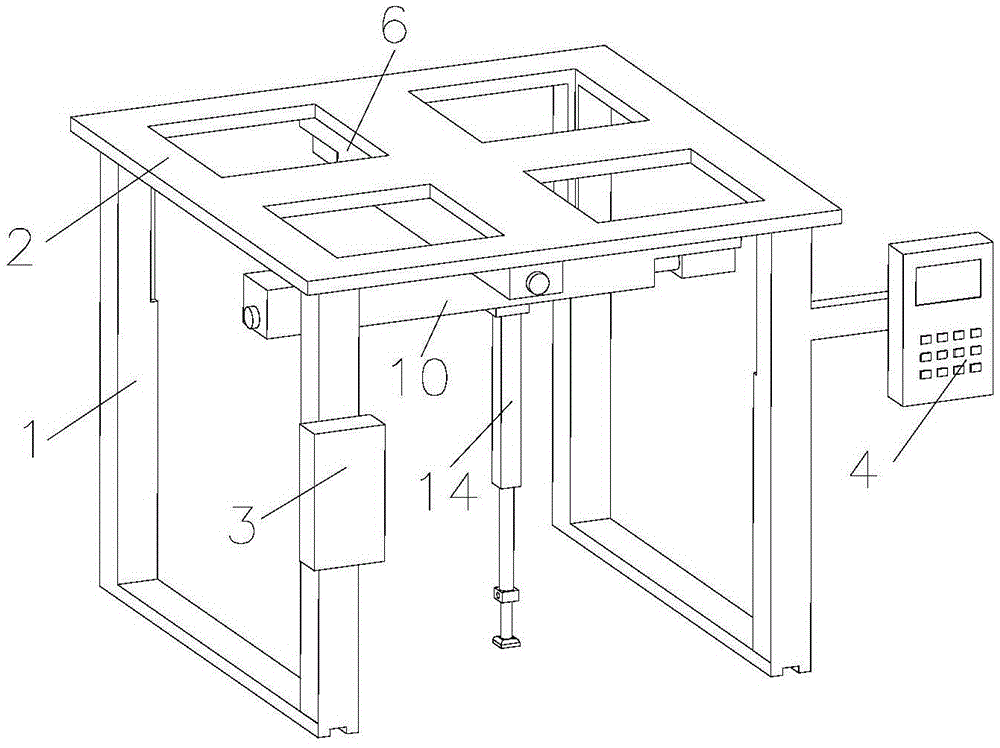

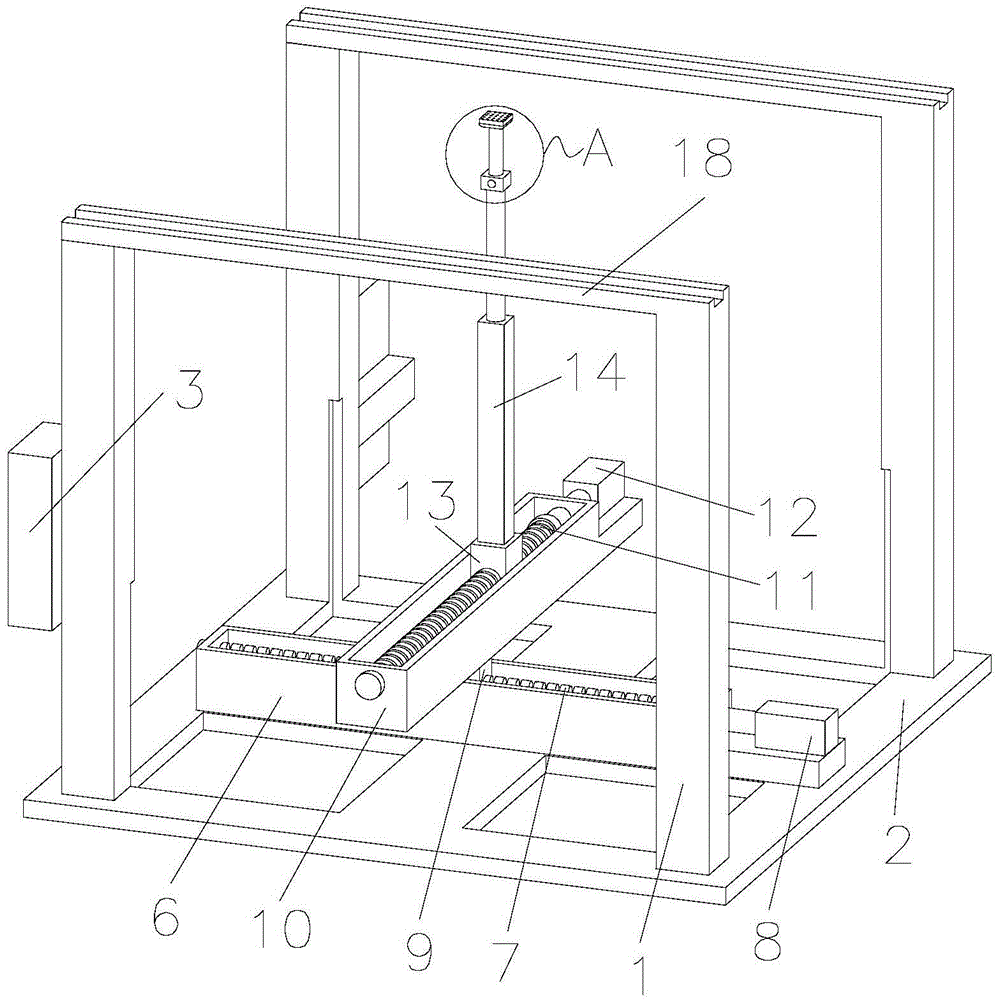

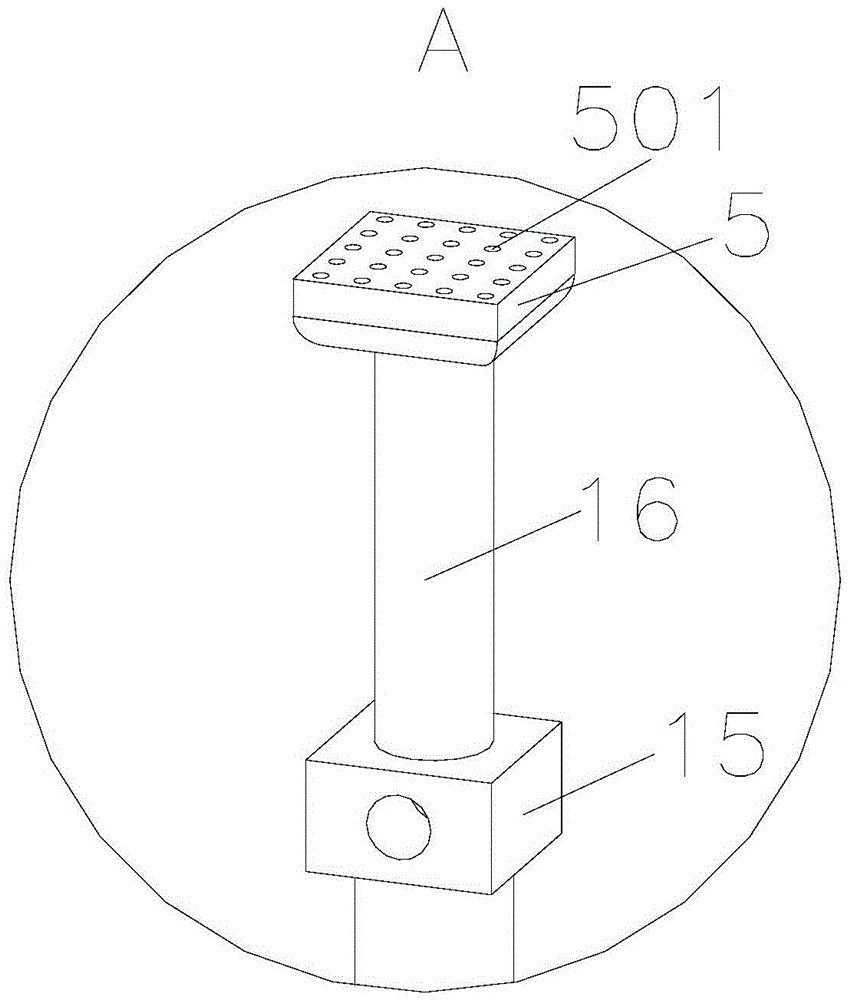

[0025] Such as Figure 1-4 As shown, an automatic auxiliary device for calibrating a solar module power tester includes a column 1, a bearing plate 2, a vacuum generator 3 and a controller 4, the column 1 is supported under the bearing plate 2, and the bearing The lower surface of the plate 2 is fixed with a Y-axis feed mechanism, and the Y-axis feed mechanism is provided with an X-axis feed mechanism, and the Y-axis feed mechanism is used to drive the X-axis feed mechanism to move along the Y-axis direction. The X-axis feed mechanism is provided with a Z-axis feed mechanism, and the X-axis feed mechanism is used to drive the Z-axis feed mechanism to move along the X-axis direction. The Z-axis feed mechanism is provided with a suction cup 5, so The vacuum generator 3 is in communication with the suction cup 5 , and the controller 4 is signal-connected with the X-axis feeding mechanism, the Y-axis feeding mechanism, the Z-axis feeding mechanism and the vacuum generator 3 respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com