Method and station for the construction of a stator winding with rigid bars for a rotary electrical machine

A technology of rotating electric machines and construction methods, which is applied in the manufacture of motor generators, electric components, electrical components, etc., and can solve the problems of discarding corresponding rods, increasing production costs, and reducing tank filling coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

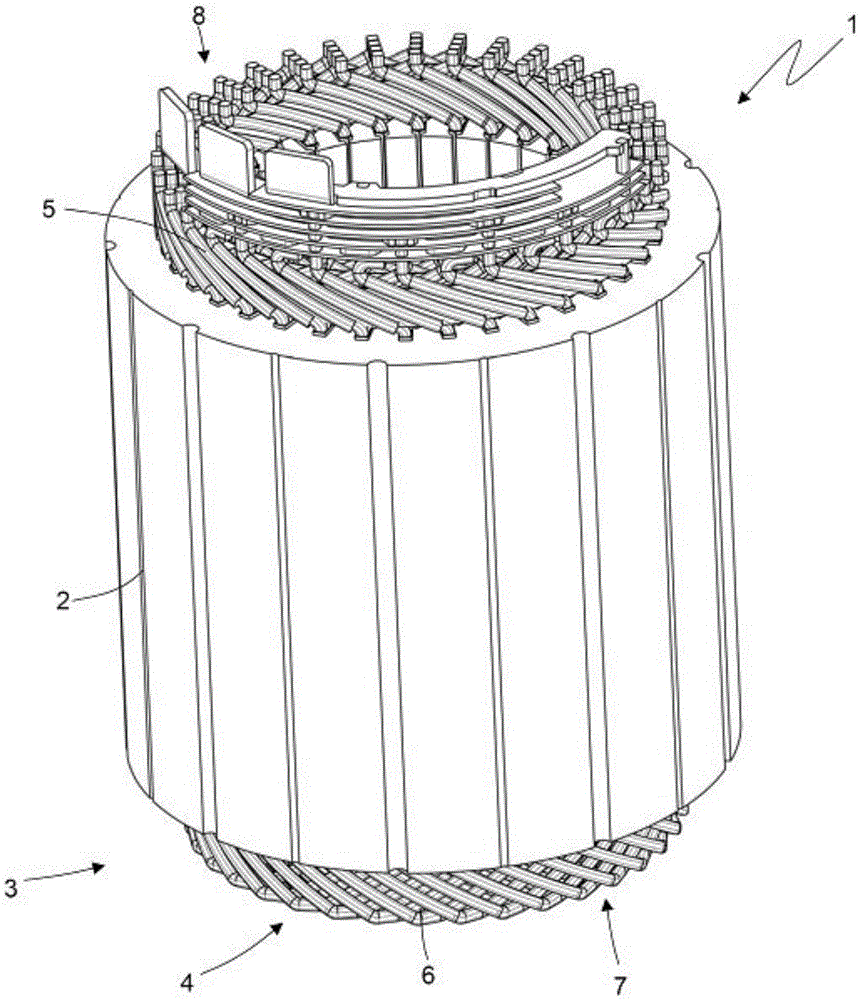

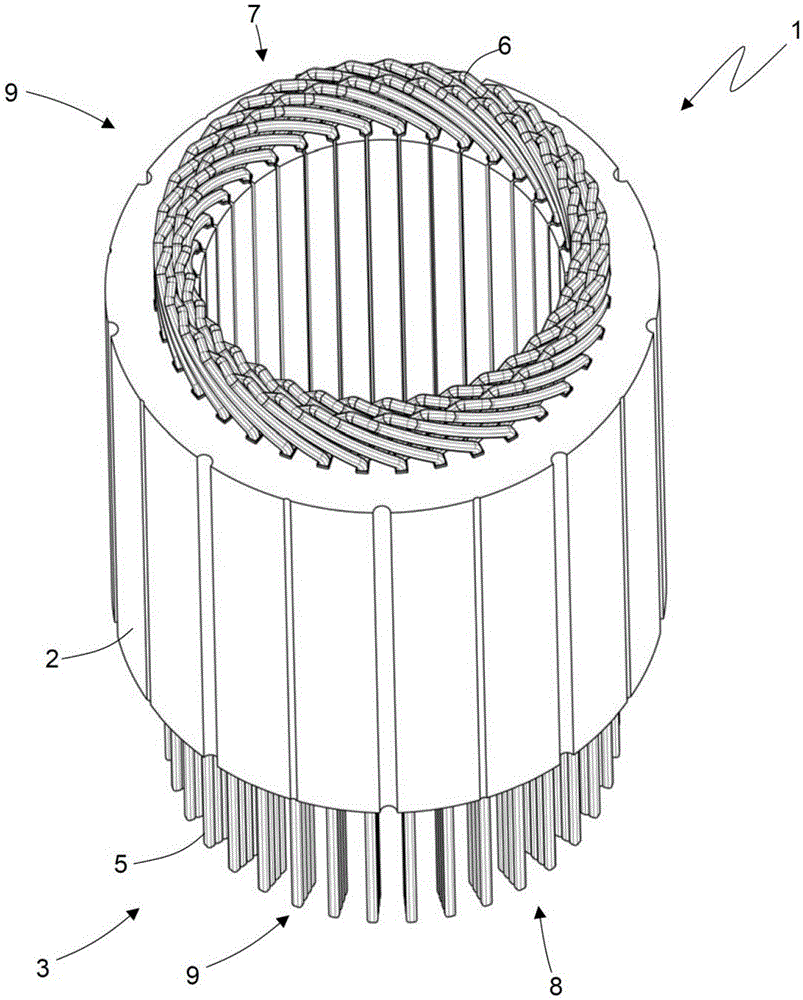

[0028] exist figure 1 In , the reference number 1 represents as a whole the stator of a synchronous motor for reversible automatic traction (that is, it can be operated as a machine by absorbing electrical energy and generating mechanical drive torque, and as an electric motor absorbing mechanical energy and generating electrical energy dynamo). The stator 1 has a cylindrical tubular shape, and is arranged around a rotor (not shown) so as to enclose the rotor itself therein.

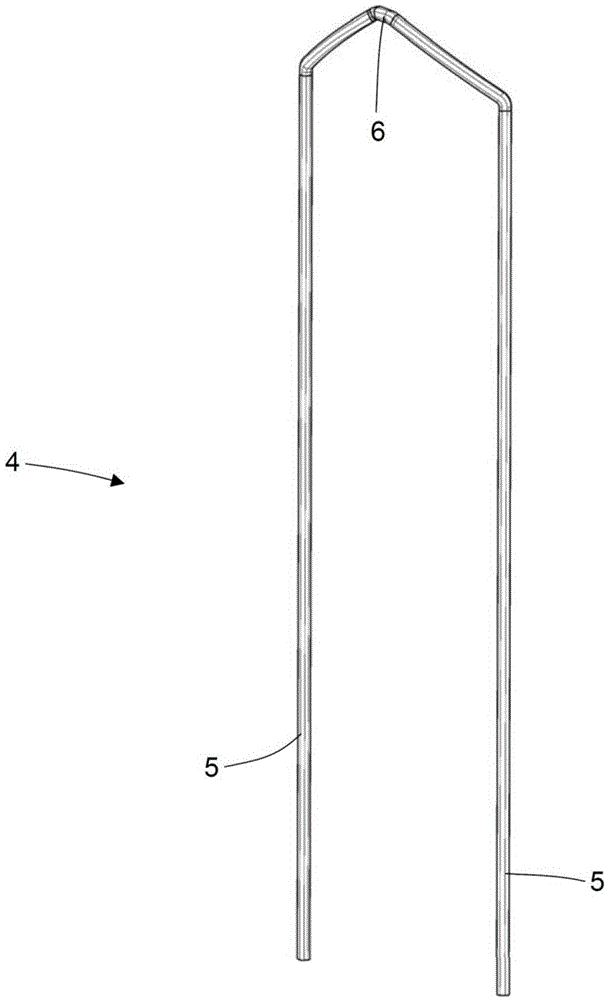

[0029] The stator 1 includes a magnetic core 2, which is composed of a series of sandwich sheets and is tubular with a central hole; the magnetic core 2 is passed longitudinally by thirty-six stator slots evenly distributed along the inner side of the magnetic core 2, and accommodates three Phase stator winding 3 (obviously the number of stator slots can be different). A three-phase stator winding 3 comprises a series of rigid U-shaped bars 4, each bar 4 comprising two legs 5 connected to each other by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com