Compound pure water filtering machine

A filter and white water technology, applied in the direction of filtration separation, filtration circuit, mobile filter element filter, etc., can solve the problems of high processing cost, high power consumption, waste of fiber, etc., to improve raw material yield, reduce cost, reduce The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

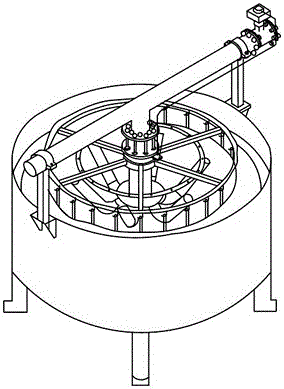

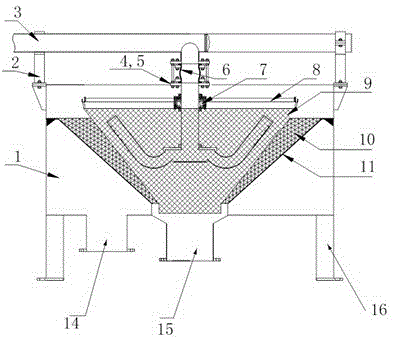

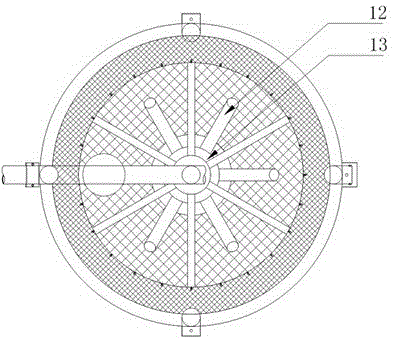

[0030] Such as Figure 1 to Figure 3 As shown, a compound white water filter includes a cylinder body 1 with a foot support 16, an inner filter screen 9 and an outer filter screen that are arranged inside the cylinder body in sequence from the inside to the outside, and are coaxial with the cylinder body 1. 10, and a "T"-shaped feed pipe 3; the outer filter screen 10 is fixed on the inner wall of the cylinder through the filter screen support plate 11; the "T"-shaped feed pipe 3 shown in the 2 Across the top of the cylinder, the "T"-shaped feed pipe 3 has a feed inlet at one end of the horizontal pipe, and a closed structure at the other end, and a discharge outlet at the end of the vertical pipe; the "T" The feeding port of the "shaped feeding pipe is equipped with a flow regulating mechanism, and the outlet of the "T" shaped feeding pipe is connected with a disc distribution head 13; in this embodiment, there are six A spray pipe 12, the spray pipe 12 forms an included angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com