A friction stir welding electric spindle device with retraction function

A friction stir welding and electric spindle technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of poor structure compactness, machine tool failure, affecting the use of welding machine tools, etc., to achieve simple structure and improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention will be described in more detail hereinafter with reference to the accompanying drawings showing embodiments of the invention. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein.

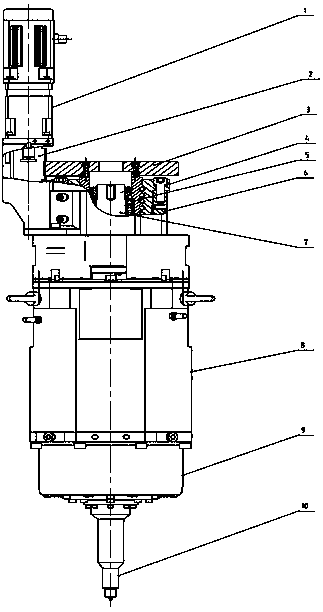

[0019] Such as figure 1 As shown, the friction stir welding electric spindle device with retraction function provided by the preferred embodiment of the present invention includes: retraction drive assembly 1, retraction gear A2, retraction gear B3, lead screw nut 4, ball screw 5, connection Part A6, internal and external spline shaft 7, built-in hollow motor 8, connector B9, stirring head 10.

[0020] The retraction drive assembly 1, the retraction gear A2, the lead screw nut 4 and the connector A6 are connected by screws; the retraction gear B3 is connected to the ball screw 5 by screws, and the ball screw 5 is connected to the internal and external spline shaft 7 through the bearing. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com