CNC lathe large size precision direct drive spindle structure

A large-scale, spindle technology, applied in bearings, shafts and bearings, control mechanical energy, etc., can solve the same or similar reports of "large-scale precision direct drive spindle structure", poor sealing effect, uneven air pressure, etc. problems, to achieve the effect of high stability and reliability, long life and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

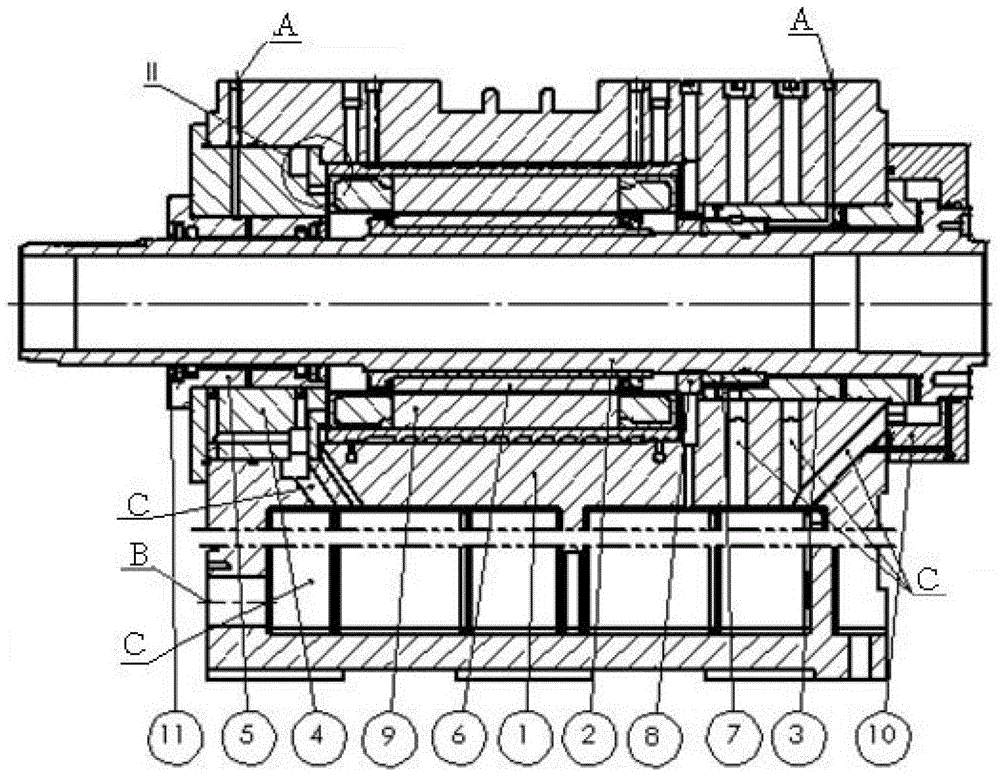

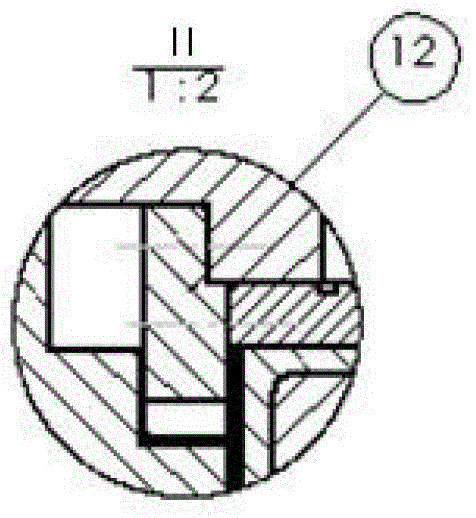

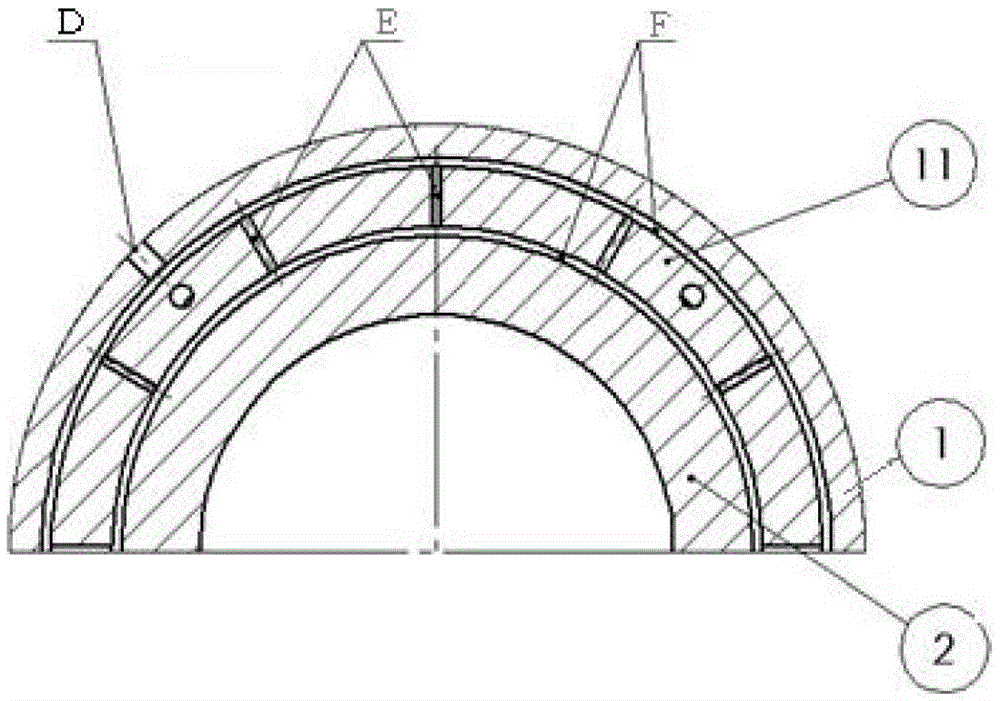

[0028] Such as Figure 1-4 Specific embodiments of the invention are given.

[0029] in the structure Figure 1-2 Among them, the hydraulic oil inlet of main shaft case 1 enters the static pressure chamber of the front and rear hydrostatic bearings to form a hydrostatic oil film, and the inner cavity at the bottom of the main shaft case is a supporting member. A static pressure cavity is formed between the rear static pressure bearings 5, and the hydraulic oil passes through the hydraulic oil leakage cavity on the main shaft housing, and flows out the leakage oil through its hydraulic oil outlet. The electric motor is a power drive system, placed between the front and rear hydrostatic bearings, and drives the main shaft 2 to rotate and work. It is characterized in that: the large-scale precision direct drive spindle is adopted, the structure is simple, the layout is reasonable, the practical application is strong, the work stability is good, the reliability is high, the spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com