A kind of automatic garlic cutting machine

A fully automatic, garlic technology, applied in metal processing, food processing, application, etc., can solve the problems of affecting root cutting efficiency, not fully realizing automatic operation, high labor intensity, etc., and achieves suitable promotion and use, ingenious structure, and labor saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but they are not used to limit the scope of the present invention.

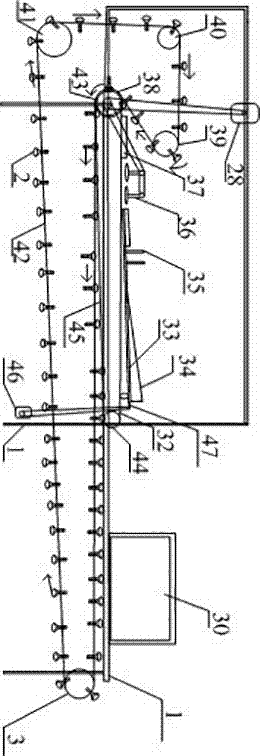

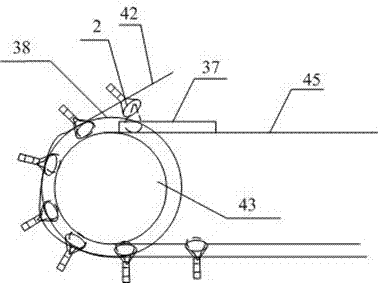

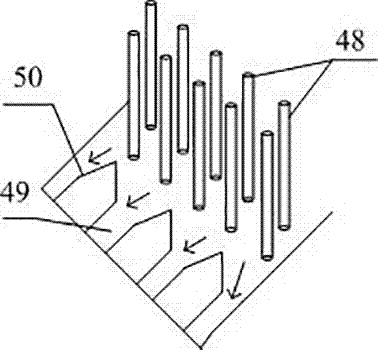

[0026] A full-automatic garlic root cutting machine, comprising a frame 1, an automatic feeding device, a motor 28, a sprocket chain transmission mechanism, and a root cutting chamber 30 positioned at the rear end of the sprocket chain transmission mechanism, the sprocket chain transmission mechanism includes a first active Sprocket 38, the first driven sprocket 39, the second driven sprocket 40, the 3rd driven sprocket 41 and the 4th driven sprocket 3, and conveying chain 42, on the described conveying chain 42 evenly distributed material Cup 2, the second driven sprocket 40, the first driven sprocket 39, the first driving sprocket 38 and the fourth driven sprocket 3 are distributed in a "Z" shape, and the third driven sprocket 41 is located Below the second driven sprocket 40,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com