Riveting and expanding bolt bar guide sleeve for fluoroplastic heat exchange tube

A technology of heat exchange tubes and fluoroplastics, which is applied in the field of tools for pneumatic riveting and expansion joints, can solve problems affecting the expansion joint effect and firmness, uneven expansion joints of metal expansion cores, orientation, and general neutrality, etc. Achieve the effects of firm, uniform and reliable expansion joints, simple structure, and improved expansion joint effect and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

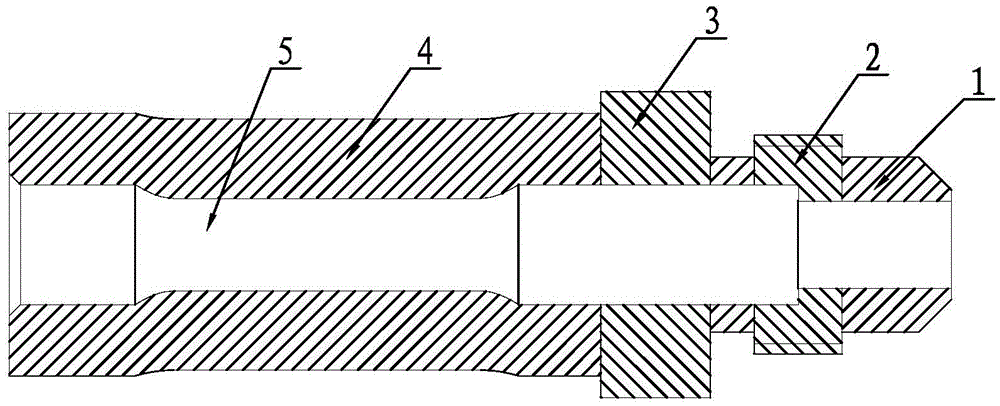

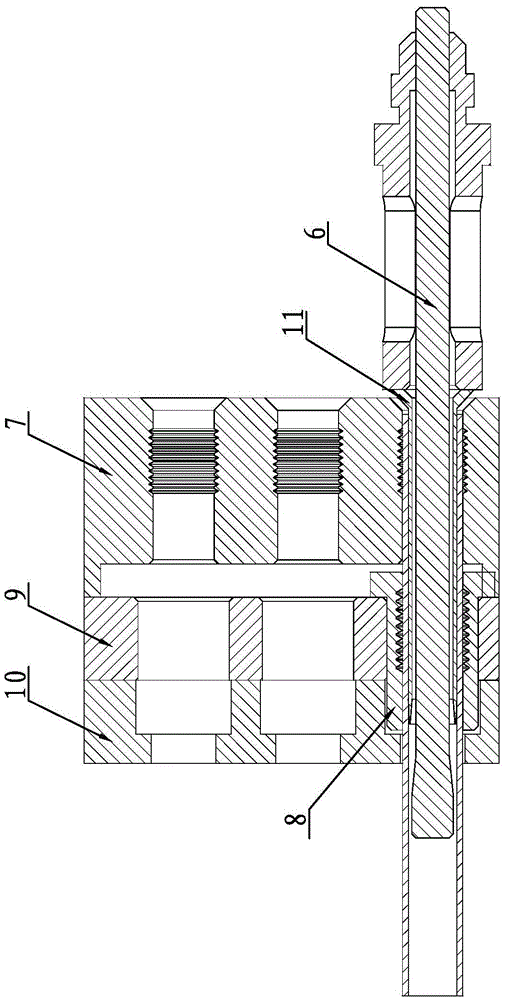

[0015] A guide sleeve for a fluoroplastic heat exchange tube riveted and expanded bolt rod, such as Figure 1-3 As shown, it includes the introduction section 1, the connecting thread section 2, the clamping section 3 and the guide section 4. The introduction section 1, the connecting thread section 2, the clamping section 3 and the guide section 4 are sequentially connected as a whole. The introduction section 1, the connecting section There is a bolt chamber 5 in the center of the threaded section 2, the clamping section 3 and the guide section 4. The bolt chamber 5 matches the diameter of the bolt 6, and the bolt 6 can move back and forth freely in the bolt chamber 5. , the diameter of the outer circle of the introduction section 1 is smaller than the opening diameter of the pneumatic riveting gun, and the guide sleeve of the bolt rod is fixed and screwed on the jaw of the pneumatic riveting gun through the connecting thread section 2 .

[0016] The using method of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com