Coaxial opposite-rotating dual-rotating-wing duct type vertical take-off and landing aircraft

A technology of vertical take-off and landing and rotor culvert, applied in aircraft, unmanned aircraft, rotorcraft, etc., can solve the problems of low application value and short battery life, and reduce the possibility of being involved in the propeller and the battery life. long, reduced aerodynamic load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

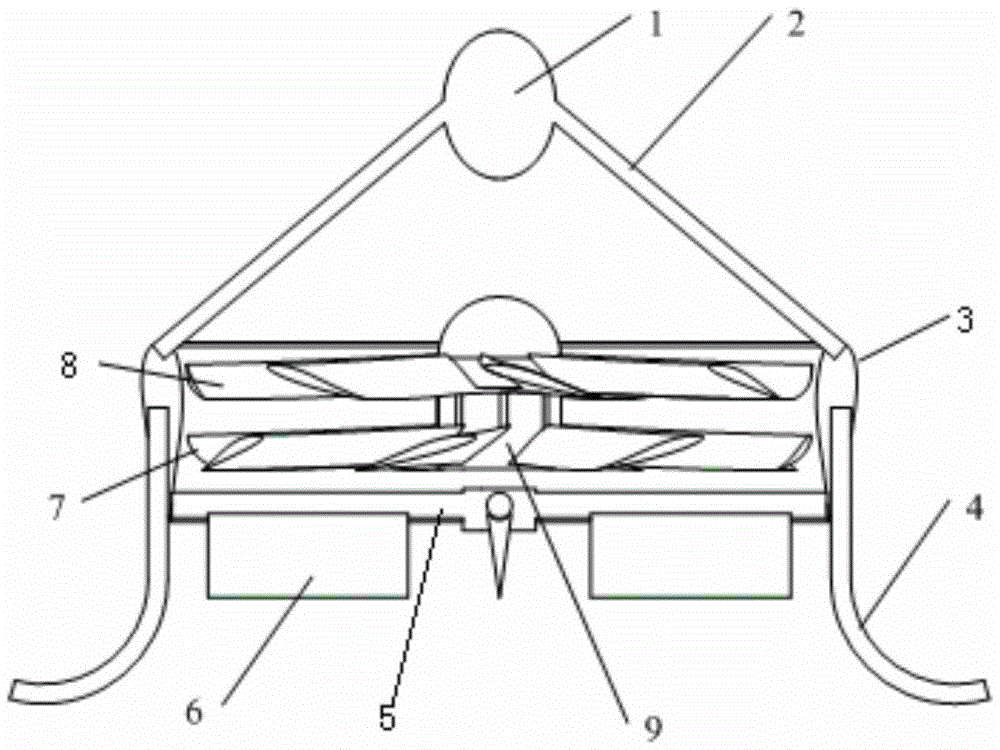

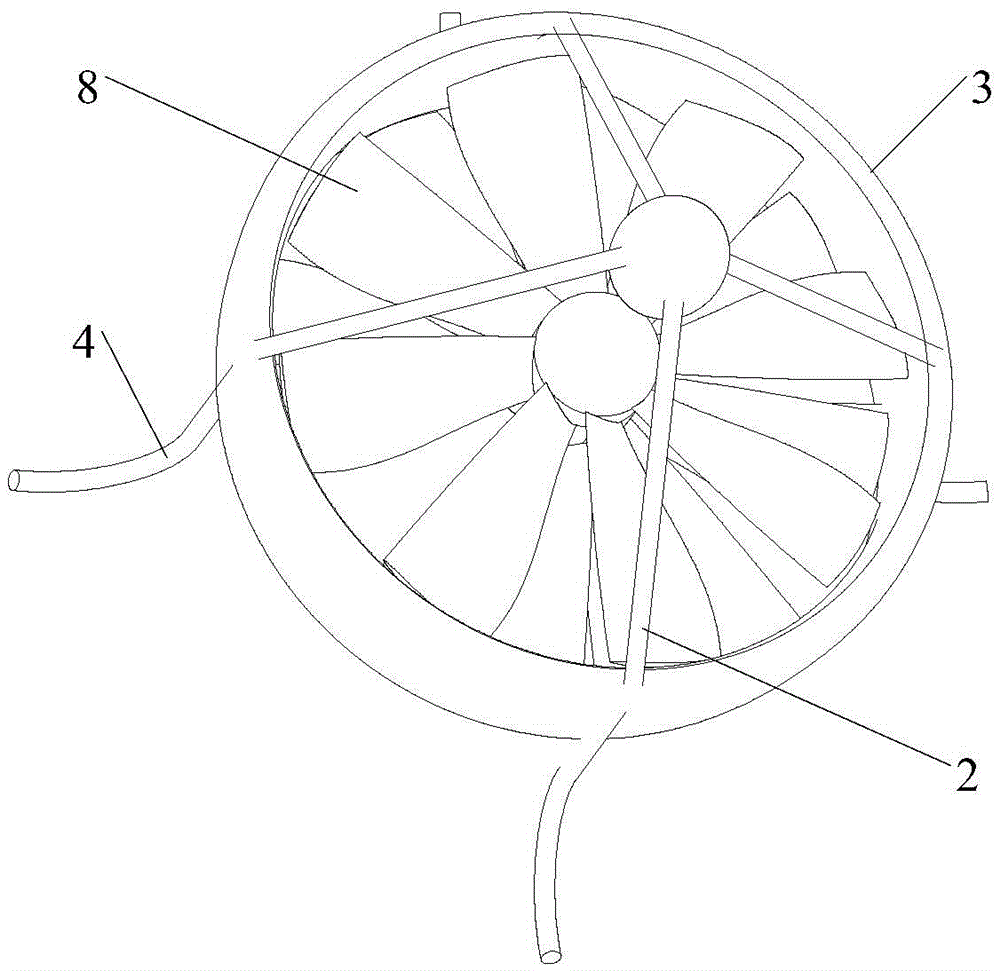

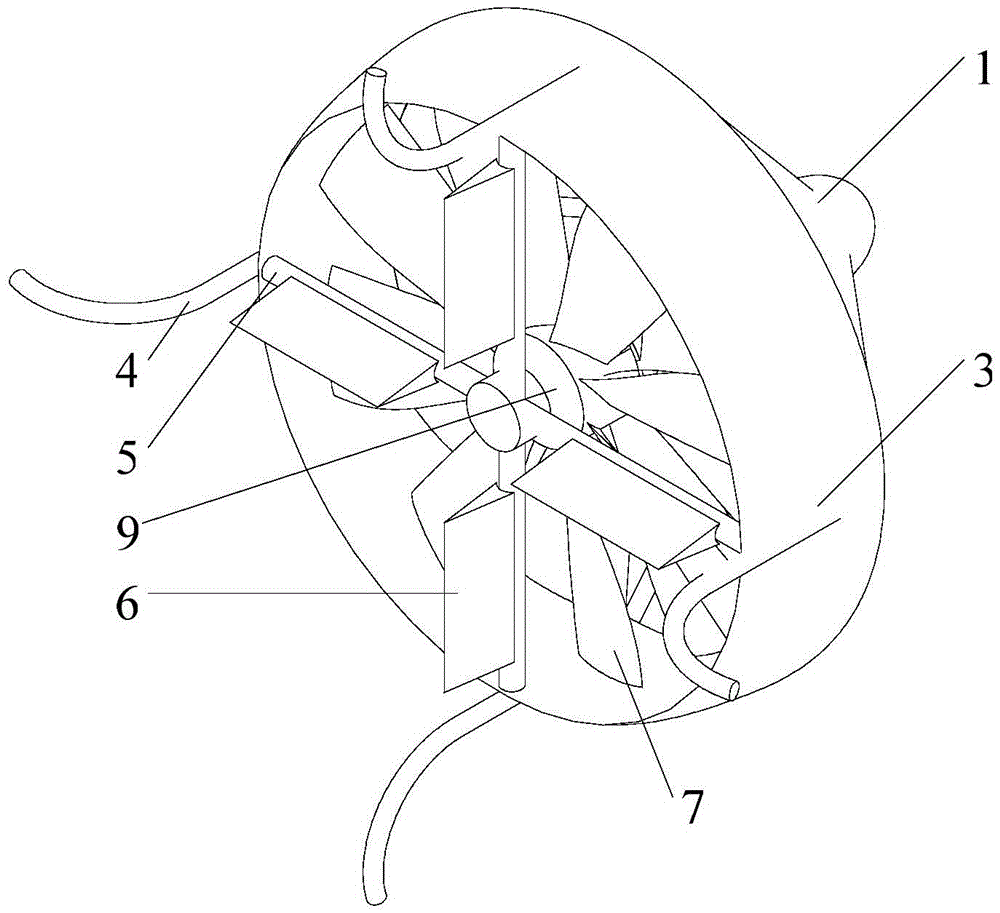

[0019] This embodiment is a coaxial counter-rotating dual-rotor ducted vertical take-off and landing aircraft.

[0020] refer to Figure 1~3 In this embodiment, the coaxial counter-rotating dual-rotor ducted vertical take-off and landing aircraft consists of a load compartment 1, a load compartment support 2, a ducted casing 3, a landing gear 4, a mounting frame 5, a diversion rudder 6, and a first rotor 7 , the second rotor 8, and a counter-rotating drive motor 9; the load compartment 1 is installed above the ducted casing 3, one end of the load compartment bracket 2 is fixedly connected to the load compartment 1, and the other end of the load compartment bracket 2 is connected to the ducted casing 3 Fixedly connected, there are multiple load compartment supports 2, and the load compartment supports 2 are evenly distributed circumferentially along the upper edge of the duct casing 3. The ducted casing 3 is a hollow annular structure, and the inner diameter of the ducted casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com