Clamp-type elevator device for heavy steel plate blank and using method thereof

A steel slab and clamping technology, which is applied in the field of clamping and lifting devices for heavy steel slabs. It can solve the problems of steel slab clamping, fastening, lack of a good technical solution, and the inability of limbs and feet to reach in, etc. problems, to achieve the effect of light weight, small deformation and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further illustrated below by specific examples.

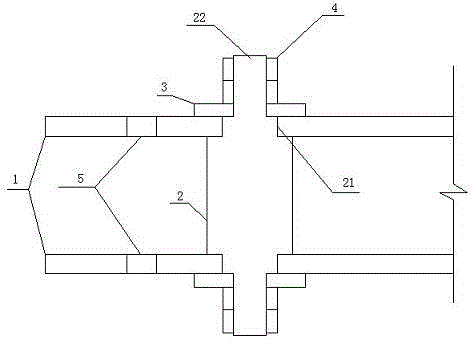

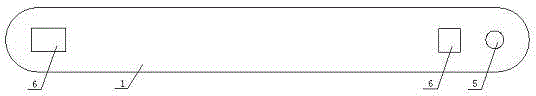

[0032] Such as figure 1 , figure 2 As shown, a clamp-type clamping and lifting device for heavy steel plate blanks, which includes two splints 1, two connecting rods 2, a number of gaskets 3 and lock nuts 4; one end of the splint 1 is provided with a lifting hole 5 and the splint 1 Both ends of the connecting rod are provided with connecting holes 6 for connecting rods to pass through, wherein the connecting holes 6 near the side of the lifting hole 5 are located inside the lifting hole 5; Section 21, the threaded locking section 22 located at both ends of the perforated section 21, the cross-sectional shape of the perforated section 21 is the same as the opening shape of the connecting hole 6, and the two splints 1 pass through the connecting holes 6 and pass through the two connecting rods 2 respectively. On the perforated section 21, the gasket 3 is set on the threaded locking section 22 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com