Hydraulic control loop for retractable ironing vibration motors and roadbed slope vibrating motors

A vibration motor and control circuit technology, applied in servo motors, roads, roads, etc., can solve problems such as inconvenient installation and complicated pipelines, and achieve the effect of improving flatness, low cost and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

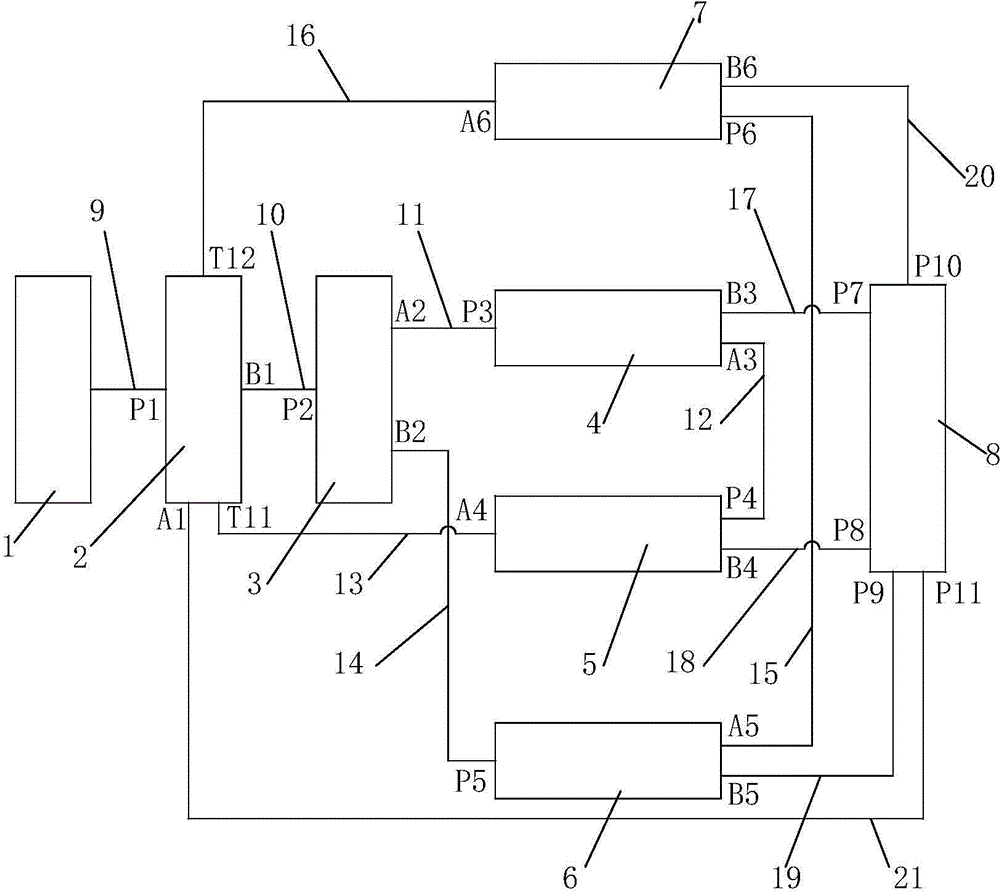

[0023] like figure 1 The hydraulic control circuit of a telescopic screed vibrating motor and roadbed slope vibrating motor shown includes an oil absorbing body 1, a hydraulic pump 2, a diverter valve 3, a left slope vibrating motor 4, a right slope vibrating motor 5, a left telescopic vibrating Tamping motor 6, right telescopic vibrating motor 7, oil return body 8, first pipeline 9, second pipeline 10, third pipeline 11, fourth pipeline 12, fifth pipeline 13, sixth pipeline 14. The seventh pipeline 15, the eighth pipeline 16, the ninth pipeline 17, the tenth pipeline 18, the eleventh pipeline 19, the twelfth pipeline 20 and the thirteenth pipeline 21; the oil suction The body 1 is connected to the oil inlet P1 of the hydraulic pump 2 through the first pipeline 9, and the working oil port B1 of the hydraulic pump 2 is connected to the oil inlet P2 of the diverter valve 3 through the second pipeline 10, and the diverter valve The working oil port A2 of 3 is connected to the oi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap