Construction method of segment girder prestressed pipeline

A technology of prestressed pipeline and construction method, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of misplacement of orifices, pipeline blockage, easy deformation, etc., and achieves prevention of deformation, compact device structure, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

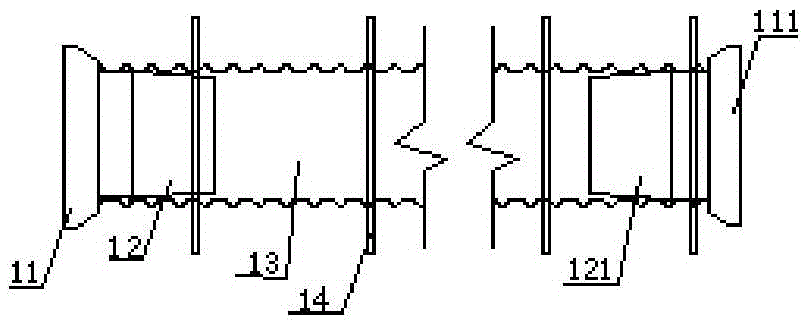

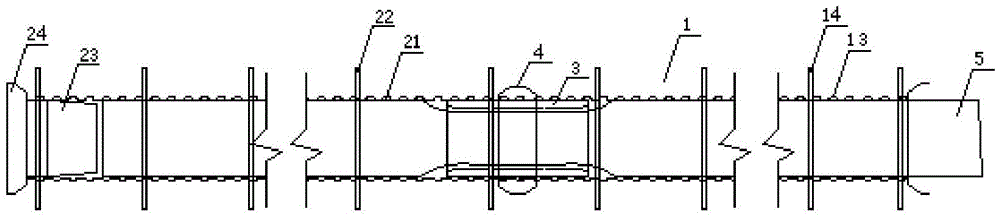

[0027] Segmental beam prestressed pipeline construction methods, such as Figure 1-5 shown, including the following steps,

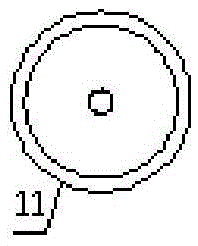

[0028] A. Install the first notch mold 11 on the template, the other end of the first notch mold 11 is fixed with the first plug 12, the outer side of the first plug 12 is sleeved with the first corrugated pipe 13, and the side wall of the first corrugated pipe 13 Fix with the first positioning steel bar 14, and fix the second plug 121 and the second notch mold 111 at the other end of the first corrugated pipe 13 in sequence, and pouring after the connection is completed to form the matching section 1;

[0029] B. The matching section 1 is removed from the template, and the first notch mold 11, the first plug 12, the second notch mold 111 and the second plug 121 at both ends of the matching section 1 are removed;

[0030] C. Sleeve the plastic pipe 3 inside one end of the matching section 1, and expose half of the plastic pipe 3; the exposed plastic pip...

Embodiment 2

[0035] Segmental beam prestressed pipeline construction methods, such as Figure 1-5 shown, including the following steps,

[0036] A. Install the first notch mold 11 on the template, the other end of the first notch mold 11 is fixed with the first plug 12, the outer side of the first plug 12 is sleeved with the first corrugated pipe 13, and the side wall of the first corrugated pipe 13 Fix with the first positioning steel bar 14, and fix the second plug 121 and the second notch mold 111 at the other end of the first corrugated pipe 13 in sequence, and pouring after the connection is completed to form the matching section 1;

[0037] B. The matching section 1 is removed from the template, and the first notch mold 11, the first plug 12, the second notch mold 111 and the second plug 121 at both ends of the matching section 1 are removed;

[0038] C. Sleeve the plastic pipe 3 inside one end of the matching section 1, and expose half of the plastic pipe 3; the exposed plastic pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com