Nuclear facility vessel cleaning device

A technology for cleaning equipment and nuclear facilities, which is applied in nuclear engineering, nuclear power generation, nuclear reactor monitoring, etc. It can solve the problem of limited accessibility at the edge of the pool, and achieve the effect of simplified construction or assembly and simple scheduling of floating platforms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

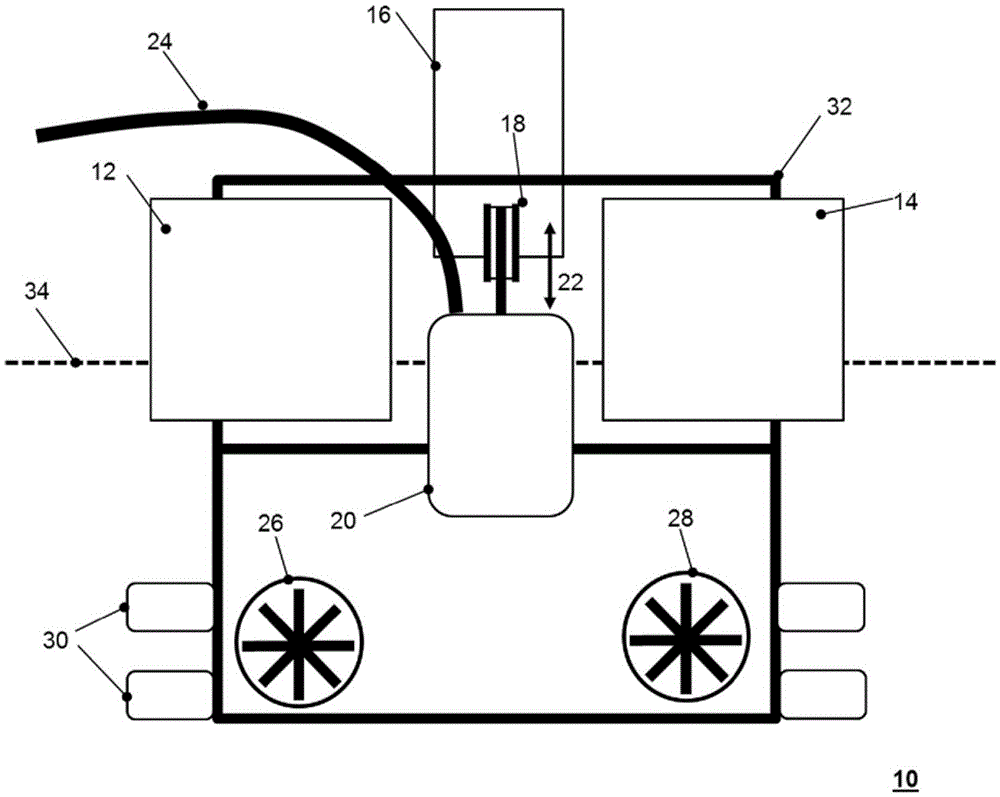

[0036] figure 1 A first example floating platform 10 is shown in side view. At the metal frame 32 , cuboid floating bodies 12 , 14 are arranged on both sides of its axial center, and these floating bodies keep the floating platform 10 floating in the water at least partially above the water surface 34 . Between the buoys 12 , 14 arranged at a distance relative to each other, a towing device 16 is provided, in this case comprising a winch with a drive, which can be moved by a rope guided via a winch wheel 18 . The pump 20 fixed at the end of the rope is hoisted up or down in the direction of the arrow 22 . The pump 20 is connected via a suction hose 24 to a storage tank, not shown, into which the pumped water is introduced.

[0037]The floating platform 10 can be fully adjusted by means of a drive device comprising a plurality of drives 26 , 28 , which, like the towing device 16 , can be remotely controlled via a remote control device (not shown). Partially surrounding dampe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com