Rotary engine with variable speed driven piston

A rotary engine and engine technology, applied to rotary piston engines, rotary or swinging piston engines, internal combustion piston engines, etc., can solve the problems of large area, low thermal efficiency, large heat loss, etc., and achieve high thermal efficiency and low frictional resistance , The effect of high torque output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Figure 1 to Figure 19 A first implementation example is shown.

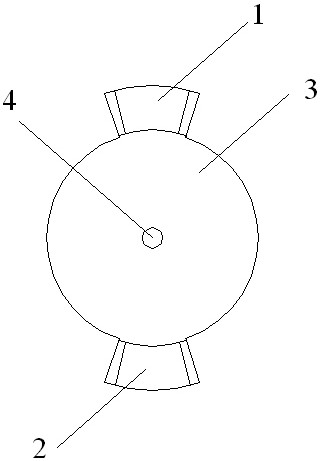

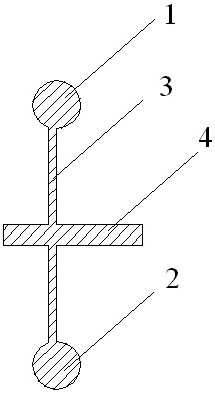

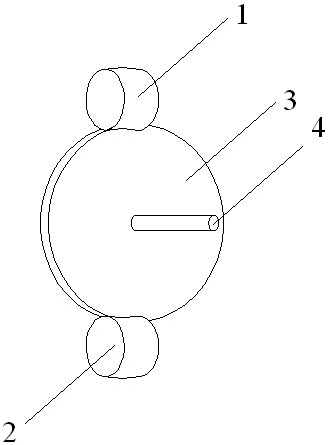

[0063] The rotary engine of this implementation case has two power pistons, figure 1 It is the front view of the power piston and power disc, figure 2 is a sectional view, image 3 It is a three-dimensional schematic diagram of the power piston and the power disc. The first power piston 1 and the second power piston 2 are fixed on the periphery of the power disc 3. The two power pistons 1 and 2 are separated by about 180 degrees. The center of the power disc 3 has PTO shaft 4, Figure 4 It is the front view of the first driven piston 5, the second driven piston 6 and the driven disc 7, Figure 5 is a sectional view, Image 6 It is a three-dimensional diagram. The first driven piston 5 and the second driven piston 6 are fixed on the periphery of the driven disc 7, and the two driven pistons 5 and 6 are separated by about 180 degrees. There is a shaft sleeve 8 in the center of the driven disc 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com