Concrete pumping equipment hydraulic system and concrete pumping equipment

A technology of concrete pump and hydraulic system, applied in mechanical equipment, fluid pressure actuating device, servo motor, etc., can solve the problems of reversing impact of concrete pumping equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

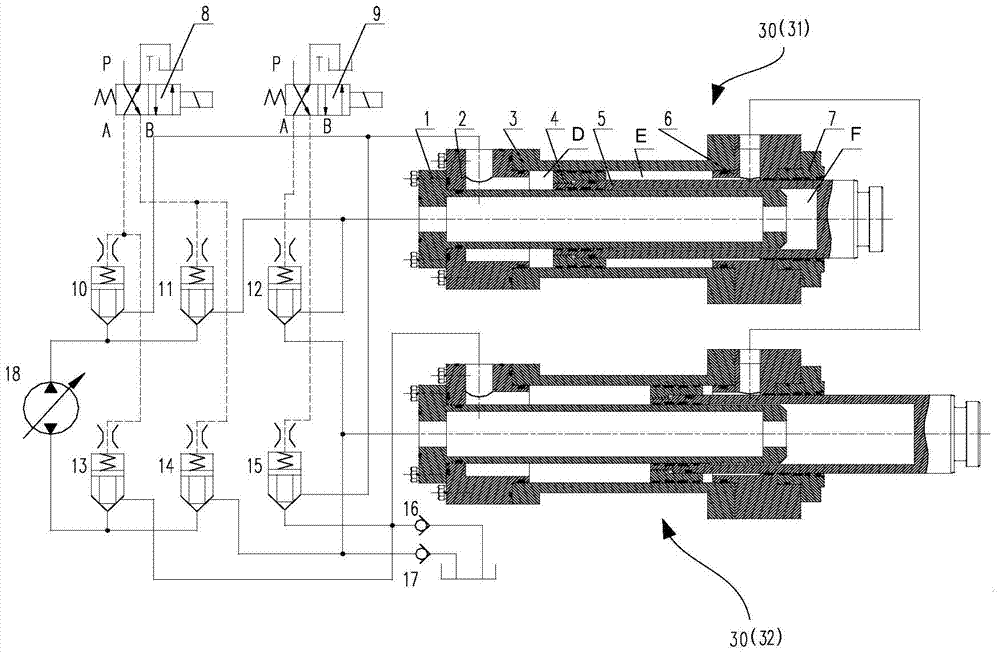

[0067] Such as image 3 with Figure 4 As shown, the two pumping cylinders 30 are respectively the first pumping cylinder 31 and the second pumping cylinder 32, and the number of reversing valves is two, which are respectively the first reversing valve 8 and the second reversing valve 9 , the number of cartridge valves is six, which are the first cartridge valve 10, the second cartridge valve 11, the third cartridge valve 13, the fourth cartridge valve 14, the fifth cartridge valve 15 and the sixth cartridge valve Install the valve 12, wherein, when the hydraulic system adopts the closed rotary pump 18 as the high-pressure oil source, the first main oil circuit and the second main oil circuit are respectively connected to the two oil ports of the closed rotary pump 18, When the hydraulic system uses an open pump as the high-pressure oil source, one of the first main oil circuit and the second main oil circuit that needs to be connected to the high-pressure oil source is conne...

Embodiment 2

[0086] Such as Figure 5 As shown, in addition to the structure in the above-mentioned embodiment 1, this embodiment also includes the seventh cartridge valve 19, the eighth cartridge valve 20 and the ninth cartridge valve 21, and the second cavity E of the first pumping cylinder 31 The seventh cartridge valve 19 is connected to the second cavity E of the second pumping cylinder 32, and the second cavity E of the first pumping cylinder 31 is connected to the first main oil circuit through the eighth cartridge valve 20. The second cavity E of the second pumping cylinder 32 is connected to the second main oil circuit through the ninth cartridge valve 21;

[0087] It also includes a third reversing valve 22, the third reversing valve 22 has a first working position and a second working position, the pilot control chamber of the seventh cartridge valve 19 is connected to the first oil port of the third reversing valve 22, Both the pilot control chamber of the eighth cartridge val...

Embodiment 3

[0092] Such as Image 6 As shown, in this embodiment, different from Embodiment 2, an open pump 24 is used in this embodiment to provide a high-pressure oil source for the hydraulic system, and a fourth reversing valve 23 is also included in this embodiment. The first oil port of the valve 23 is connected to the open pump 24, the second oil port is connected to the oil tank, the third oil port is connected to the first cartridge valve 10, the second cartridge valve 11 and the eighth cartridge valve 20, The fourth oil port is connected with the third cartridge valve 13 , the fourth cartridge valve 14 and the ninth cartridge valve 21 .

[0093] More preferably, the fourth reversing valve 23 is a three-position four-way reversing valve. When the fourth reversing valve 23 is in the first working position, the open pump 24 and the third cartridge valve 13 and the fourth cartridge valve 14 and the ninth cartridge valve 21 are connected, and the oil tank is connected with the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com