Sliding-flap free-float type

A technology of traps and float balls, applied in steam traps, mechanical equipment, etc., can solve the problems of steam leakage, large starting force, waste of energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

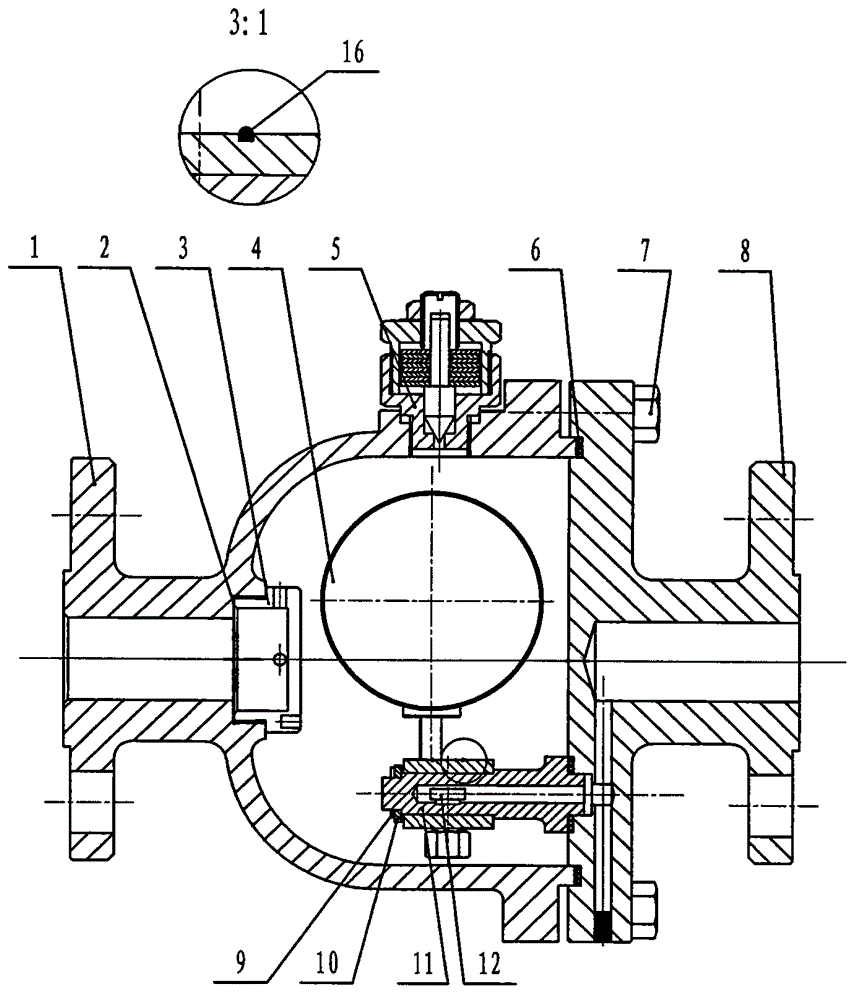

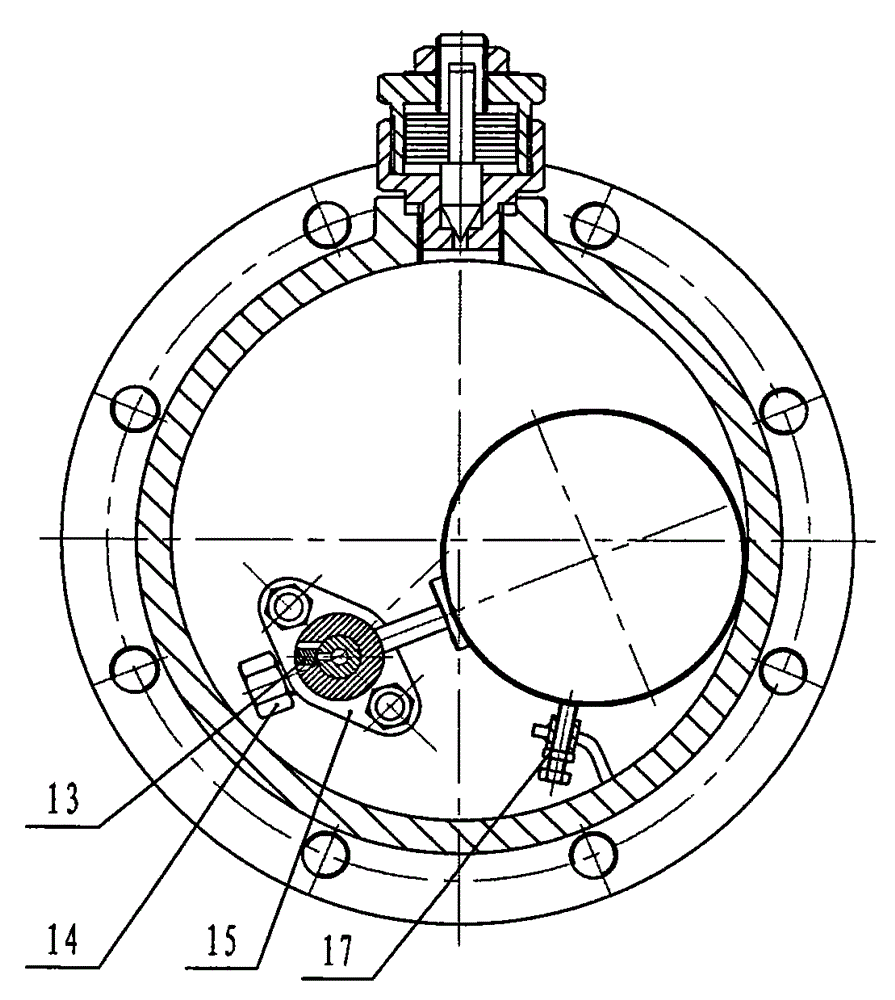

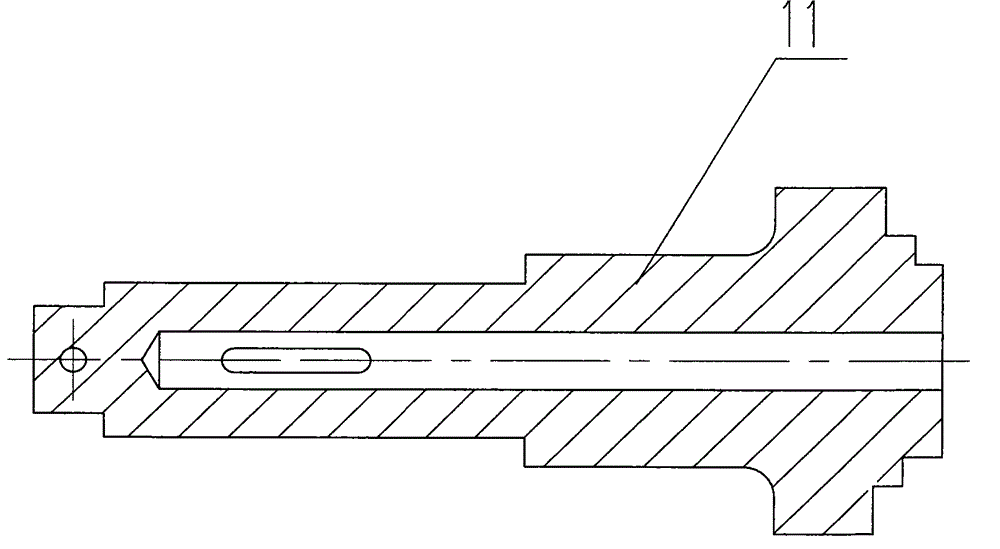

[0012] As shown in the figure, the left valve body 1 and the right valve body 8 are connected by bolts 7 to form a casing, the left valve body 1, the filter screen 2 and the plug 3 are connected in sequence, and the top of the left valve body 1 is equipped with an automatic emptying valve 5 to limit The positioning device 17 is fixed in the left valve body cavity, the floating ball 4, the shaft sleeve 12, and the counterweight 14 are solidified together and set on the valve shaft 11, the counterweight 14 is adjustable, the cotter pin 9, the flat washer 10, the valve The shaft 11, the gland 15, and the right valve body 8 are connected in sequence, and the side of the bushing 12 is processed into a "convex"-shaped hole, the upper part of the "convex" shape is a waist-shaped hole, and the lower part is a rectangular hole, between the valve disc 13 and the rectangular hole For clearance fit, two ring springs 16 are used to press the valve disc 13 on the outer circumference of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com