Stepped heat storage system and stepped heat storage method

A heat storage system and heat storage technology, applied in the field of heat storage systems, can solve the problems of high cost, complex structure, limited thermal energy output stability, etc., and achieve the effects of low cost, simple structure, and flexible operation scheduling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

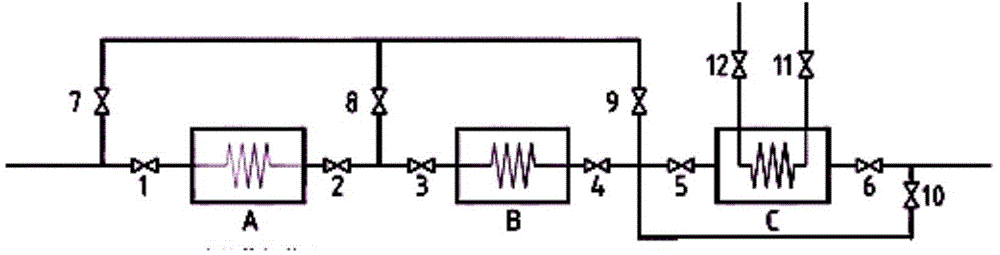

[0071] For main line valve design:

[0072] Set the first valve 1 in the first main road pipeline;

[0073] Set the second valve 2 and the third valve 3 in sequence in the second main pipeline; wherein, the second valve 2 is close to the solid heat storage heat exchanger A, and the third valve 3 is close to the phase change heat storage heat exchanger B;

[0074] Set the fourth valve 4 and the fifth valve 5 in sequence in the third main pipeline; wherein, the fourth valve 4 is close to the phase change heat storage heat exchanger B, and the fifth valve 5 is close to the molten salt steam superheater C;

[0075] The sixth valve 6 is set in the fourth main road pipeline.

[0076] For bypass line valve designs:

[0077] The first bypass pipeline and the second bypass pipeline have a first common pipeline; the second bypass pipeline and the third bypass pipeline have a second common pipeline;

[0078] Set the 8th valve 8 in the first public pipeline; set the 9th valve 9 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com