3D-printed counter-current chromatography separation column for and chromatographic instrument

A countercurrent chromatography and 3D printing technology, which is applied in the field of countercurrent chromatography separation columns and chromatographs, can solve the problems of limited development of countercurrent chromatographic columns, difficult innovation of pipeline structure, easy damage of pipelines, etc., to increase the interaction of solutions Force and mixing strength, improved distribution efficiency, and improved separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

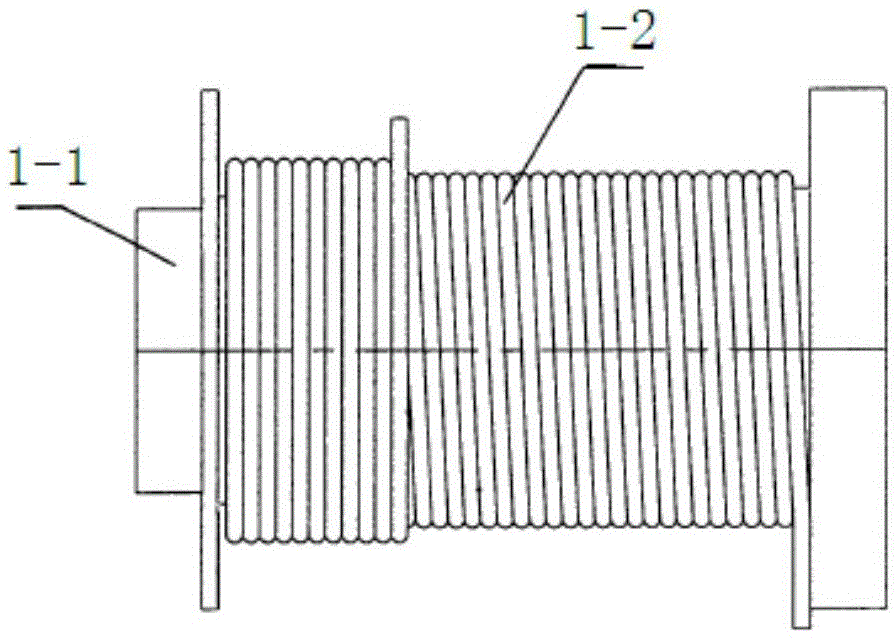

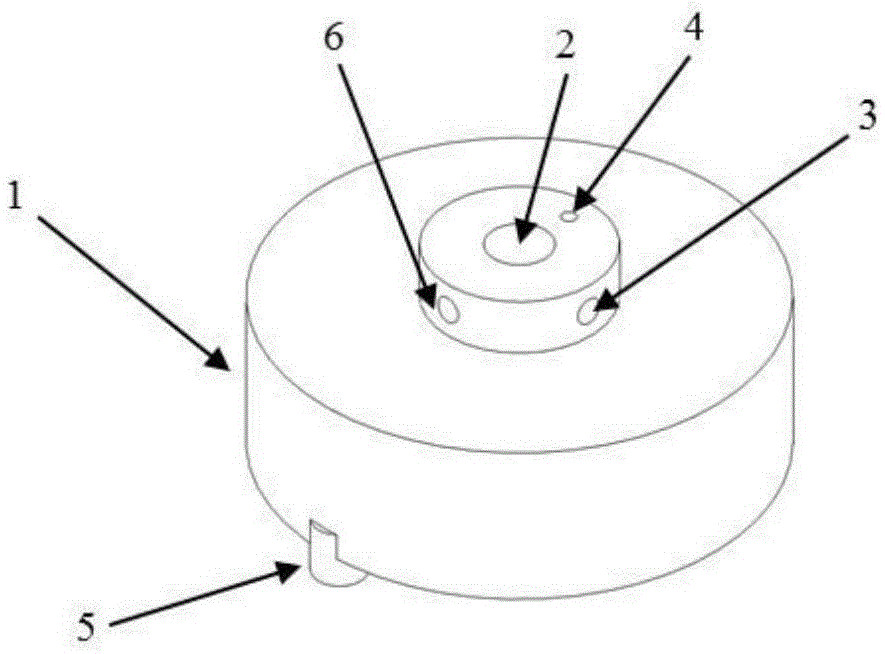

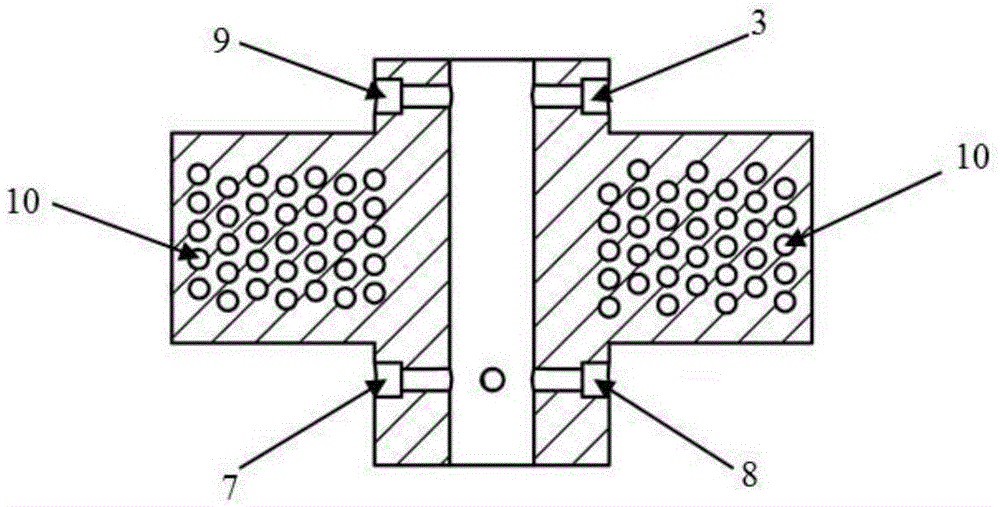

[0028] The structure of the present invention is as figure 2 , image 3 As shown in the figure, the 3D printed countercurrent chromatography separation column has an integrated structure of the pipeline and the support column by 3D printing technology.

[0029] Further, the countercurrent chromatographic separation column 1 is a columnar structure, and a cylindrical protrusion coaxial with the columnar structure is provided at the center of the top and bottom of the columnar structure, and a columnar structure and two cylindrical protrusions are provided along the center of the cylindrical protrusion. The central axis perforation 2 in the center of the shaped protrusion is provided with central axis fixing screw perforations 3, 6, 7, 8, 9 on the sides of the two cylindrical protrusions; the sample inlet 4 is provided on the cylindrical protrusion at the top, There are multiple circles of cylindrical channels 10 used to replace the original pipelines in the columnar structure...

Embodiment 2

[0035] A chromatograph, the countercurrent chromatographic separation column adopts the 3D printed countercurrent chromatographic separation column designed in Example 1.

[0036] Aiming at the technical difficulties existing in conventional countercurrent chromatography separation columns, the present invention develops a countercurrent chromatography separation column based on 3D printing, which can print out tube shapes of any structure through drawing software, and then directly print them through 3D printing technology, and because the tube The road and the supporting column are integrally formed by 3D printing technology, so when the length of the pipeline is as long as that of the prior art, the volume of the separation column of the present invention is obviously smaller than that of the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com