Fully-automatic thin-layer chromatography planking machine

A thin-layer chromatography, fully automatic technology, applied in the field of thin-layer chromatography preparation devices for chemical experiments, can solve the problems of insufficient grinding, large experimental influence, time-consuming and labor-intensive, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

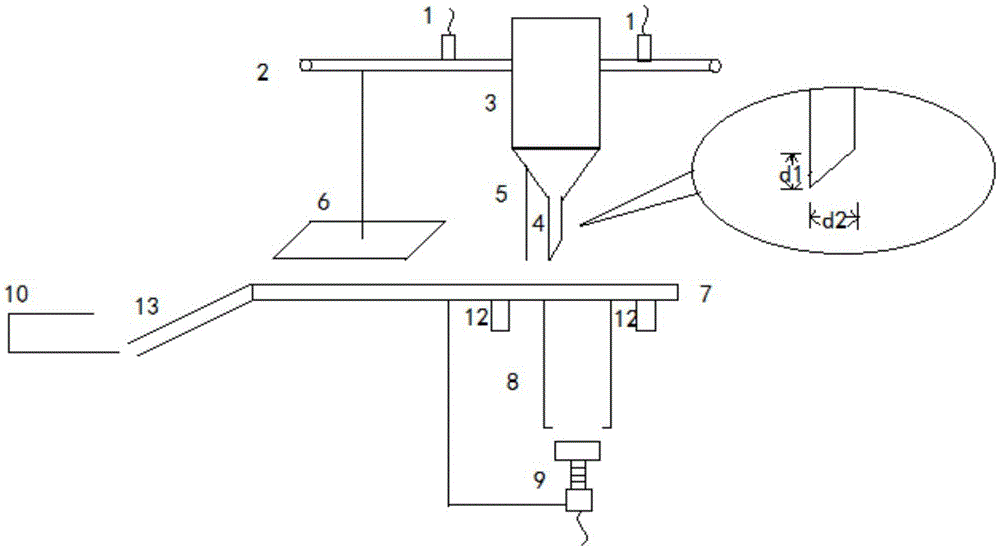

[0025] Example 2. One-time automatic preparation of 30 chromatography plates with a thickness of 2mm and a size of 10cm*20cm

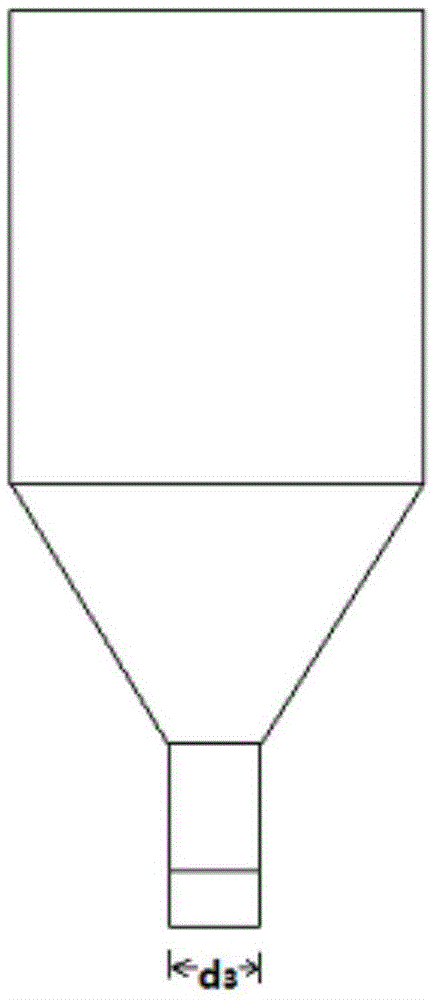

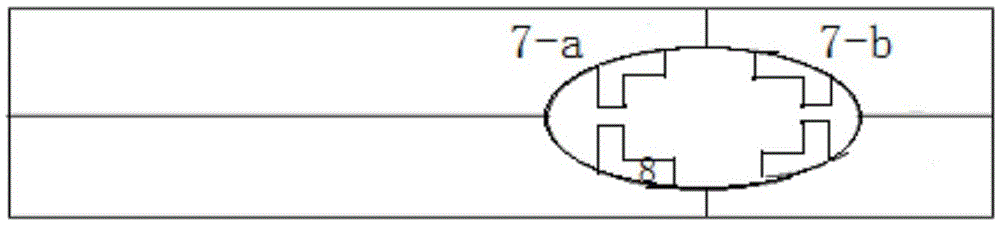

[0026] When the program setting requires 30 chromatographic plates with a thickness of 2mm and a size of 10cm*20cm, 30 glass plates are placed in the storage tank 8, and the required materials are poured into the mixing tank 3. The program starts, the materials are uniformly mixed by ultrasonic and air bubbles are shaken. At the end of the set time, the spiral column 9 adjusts the glass sheet to a position 2mm from the horizontal plane of the fixing table 7. At this time, a No. Ⅱ 10cm blanking port 4 is used, and the four parts of the fixing table 7 are in accordance with the size of the glass sheet. Adjust to a suitable size, the mixing tank 3 and its connected discharging port 4, and the scraper plate 5 move from left to right until it touches the contact sensor 1 on the right, so that the screw column 9 is screwed up to the bottom of the glass sheet. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com