Shale gas volume fracturing micro-earthquake monitoring method

A micro-seismic and shale gas technology, applied in seismic survey, seismology, geophysical survey, etc., can solve the problems of describing the shape of fracturing fractures, poor pertinence of shale gas platform wells, and susceptibility to background noise , to achieve the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

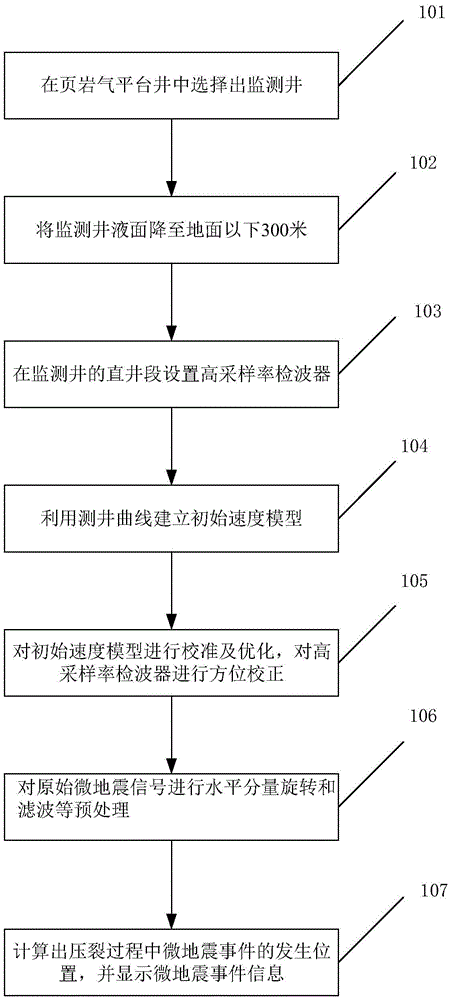

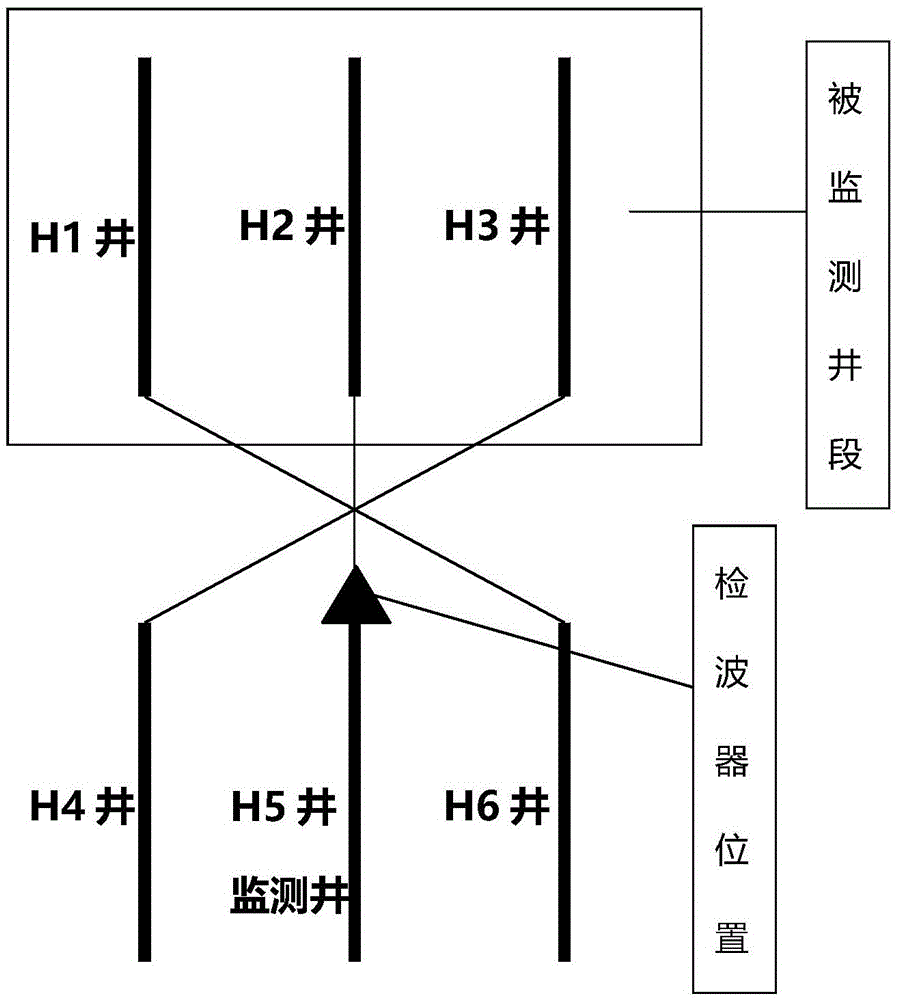

[0034] see figure 1 and figure 2 , the embodiment of the present invention provides a shale gas volume fracturing microseismic monitoring method, the method includes the following steps:

[0035] Step 101: Select monitoring wells among the shale gas platform wells according to factors such as the maximum monitoring range of the shale gas platform wells, the cementing quality at the instrument deployment location, background noise, and actual construction requirements.

[0036] According to the maximum monitoring range of shale gas platform wells, the fracturing wells on the platform must be within the monitoring range; the location of the instrument deployment should avoid the location with poor cementing quality; noise sources should be eliminated, and the same platform and fracturing wells should be avoided. cause interfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com