Hard-to-hard LCD screen binding method

A liquid crystal screen, hard-to-hard technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve problems such as uneven stress distribution, cumbersome binding process, and weak adhesion, so as to achieve no anti-bubble phenomenon and reduce The effect of cost, efficiency and yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

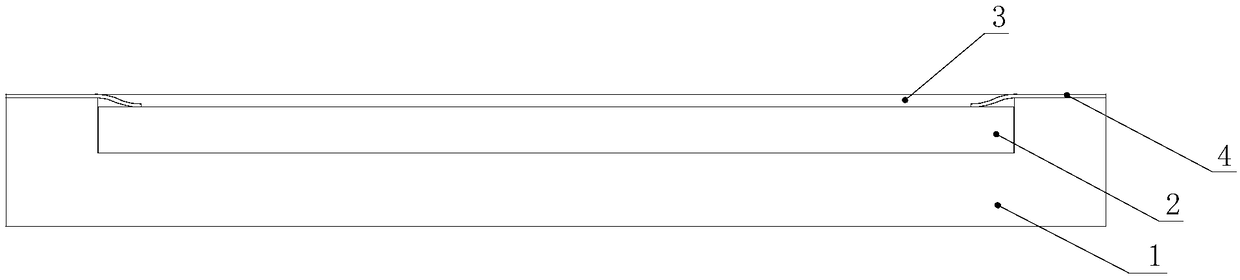

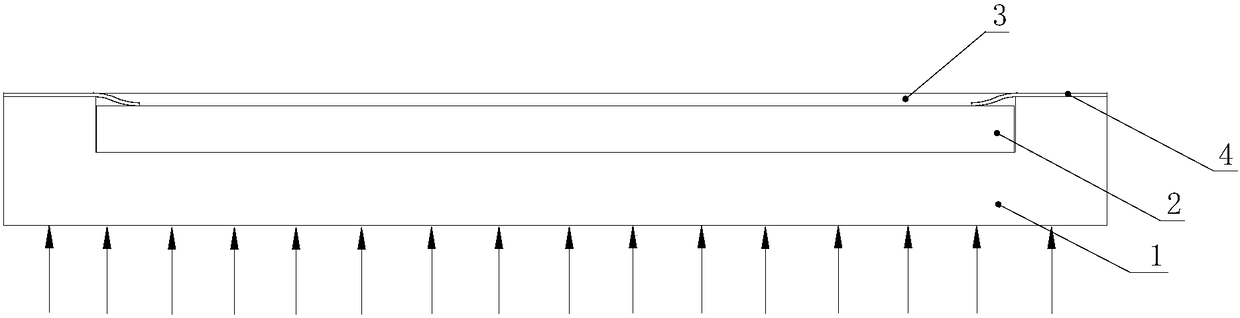

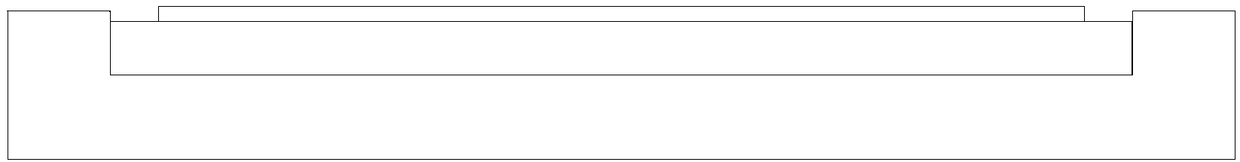

[0028] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

[0029] The invention provides a hard-to-hard LCD screen binding method, comprising the following steps:

[0030] (1) Glue is applied to the functional glass;

[0031] (2) pre-curing the glue applied to the functional glass;

[0032] (3) Complete the construction of the glue layer;

[0033] (4) Bind the functional glass with the adhesive layer to the LCD screen in position.

[0034] Specifically, in step (1), the glue used is a silicon-based glue, which is not only soft but also can effectively reduce the binding stress; if it is necessary to enhance the binding strength, you can mix some Polyu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com