Auxiliary wire arranging and drawing mechanism and automatic winding machine

A technology for pulling and arranging wires, which is applied to automatic winding machines. field, it can solve problems such as loose coil arrangement, broken enamelled copper wire, deformation, etc., and achieve the effect of simple structure and winding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

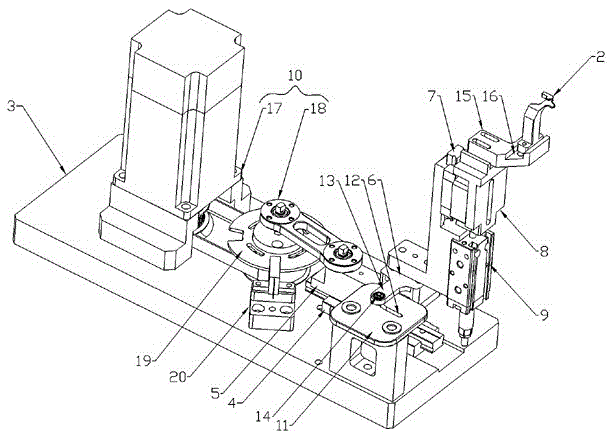

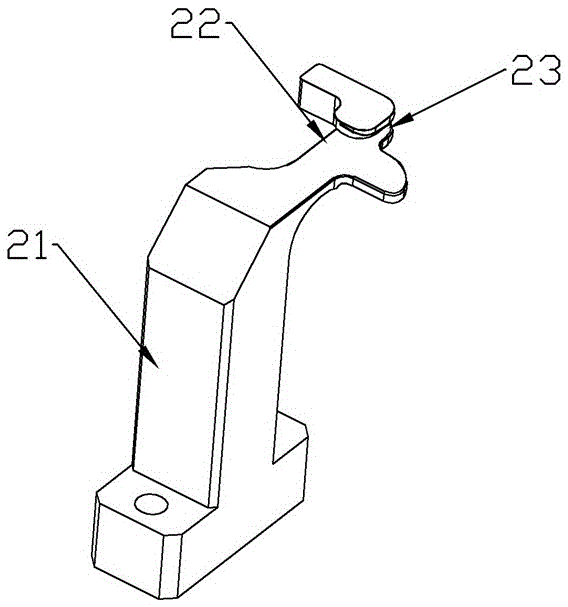

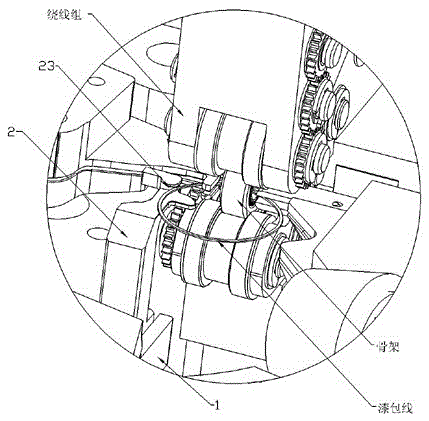

[0017] Such as figure 1 , figure 2 with image 3 As shown, in this embodiment, the auxiliary wire arrangement and wire pulling mechanism includes a driving mechanism 1 and a wire pulling head 2 arranged on the driving mechanism 1. When working, the driving mechanism 1 drives the wire pulling head 2 to press The set track toggles.

[0018] In this embodiment, the driving mechanism 1 includes a base 3, an X-axis slide 4 arranged on the base 3, an X-axis slide 5 slidably connected with the X-axis slide 4, and the The Y-axis slider 6 slidably connected to the X-axis slider 5, the Z-axis slider 7 arranged on the Y-axis slider 6, and the Z-axis slider 8 slidably connected to the Z-axis slider 7, so The wire pulling head 2 is arranged on the Z-axis slider 8, the Z-axis slider 7 is also provided with a Z-axis driving mechanism 9 connected with the Z-axis slider 8, and the base 3 is provided with There is an X-axis driving mechanism 10 connected with the X-axis slider 5, a limit b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com